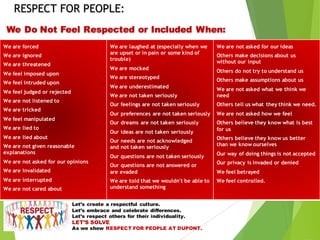

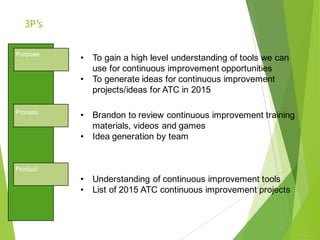

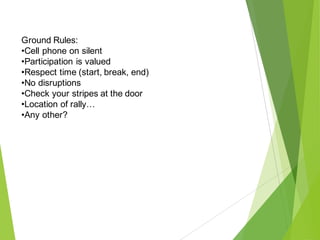

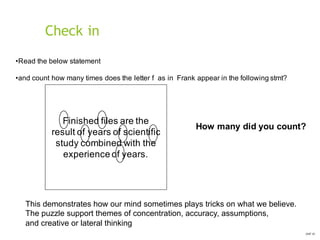

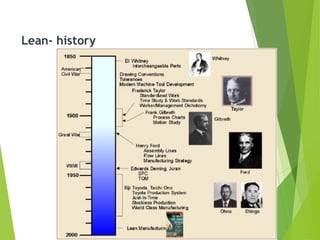

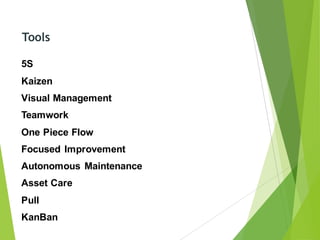

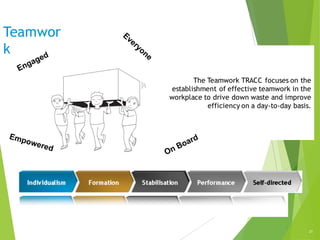

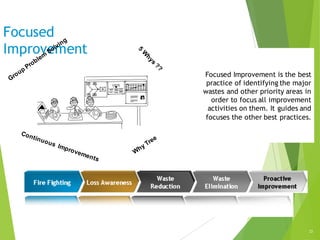

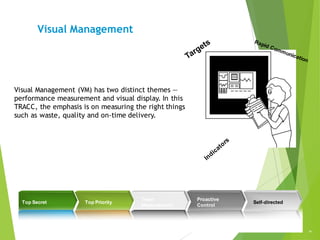

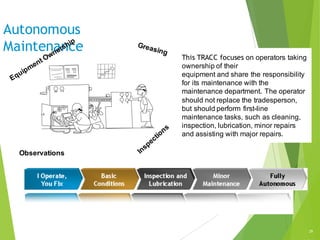

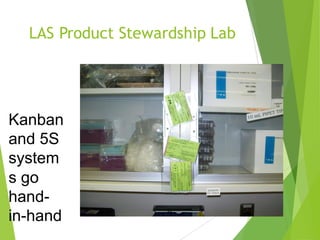

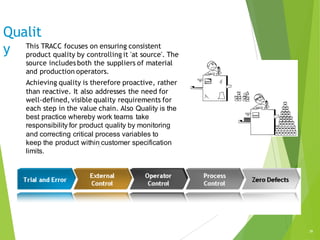

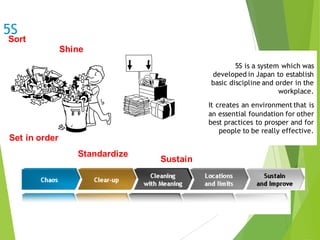

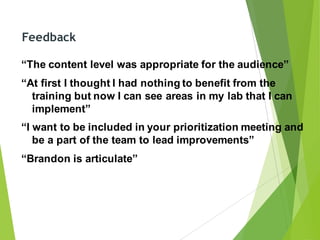

The document discusses continuous improvement at DuPont through respect for people. It outlines values of safety, environmental stewardship, ethics and respect. Respect for people involves creating a respectful culture that embraces differences and individuality. The document then lists ways that people may not feel respected or included. It provides an agenda for a meeting covering continuous improvement tools and generating project ideas. The meeting reviews concepts like lean, waste elimination and goals of variability, visibility and velocity. Opportunities and tools for improvement are discussed, including 5S, visual management and autonomous maintenance.