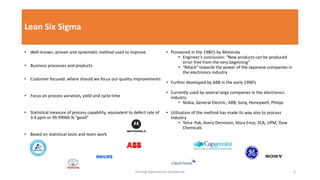

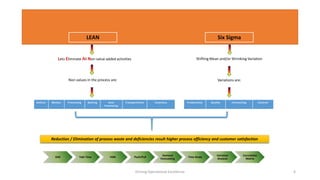

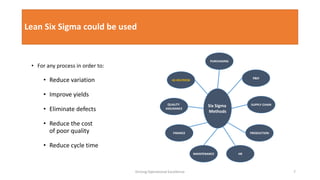

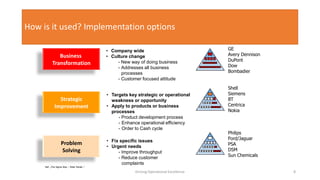

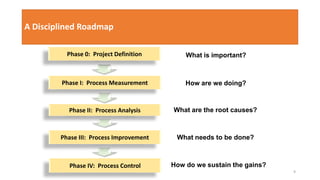

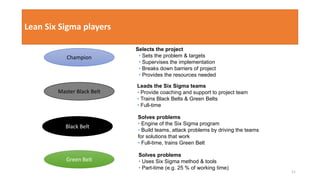

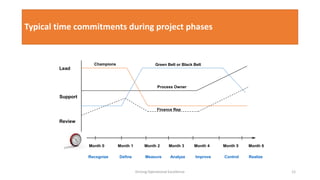

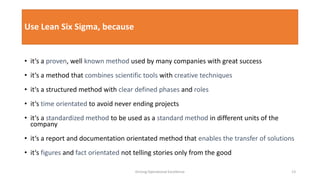

Lean Six Sigma is a systematic method used to improve business processes, products, and quality. It focuses on reducing process variation and cycle time through the use of statistical tools and teamwork. The method was pioneered in the 1980s and is now used by many large companies. Lean Six Sigma projects follow a defined roadmap of measuring the current process, analyzing root causes of defects, improving the process, and controlling the gains. Projects are led by a Black Belt with support from a Green Belt, Champion, and other roles using defined phases and tools. Using Lean Six Sigma provides benefits such as proven success, a structured approach, and fact-based results.