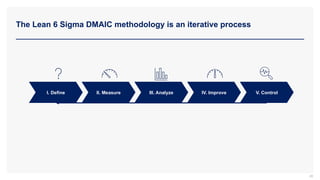

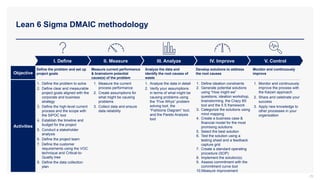

The Lean 6 Sigma Toolkit, developed by ex-McKinsey, Deloitte, and BCG consultants, provides frameworks, best practices, and templates to implement Lean Six Sigma methodologies for process improvement. It emphasizes reducing complexity and increasing reliability through the DMAIC (Define, Measure, Analyze, Improve, Control) approach, which aims to eliminate waste and enhance efficiency in organizations. Successful case studies, like Motorola's $16 billion savings and improved customer satisfaction, demonstrate the effectiveness of Lean Six Sigma in various industries.

![High-level current process and scope

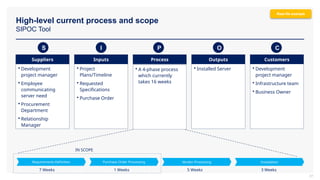

SIPOC Tool

33

Start point: [insert your

own text]

Process Name: [Identify the process to be worked on]

Process Owner: [Confirm the process owner]

End point: [insert your

own text]

Insert the

suppliers to the

process

Suppliers Inputs Outputs Customers

Process

Insert inputs

provided by

suppliers

Insert tangible

outputs

Insert the

customers of the

process

List what are the necessary

requirements for process

Process Requirements

List what is critical to customer

Customer Requirements

Insert your own text

Insert your own text

Insert your own text

Insert your own text

Insert your own text

In scope

Out of scope](https://image.slidesharecdn.com/13-240912093714-3eec5ba2/85/13-_Lean_6_Sigma_Toolkit_-_Overview_and_Approach-pptx-33-320.jpg)

![High-level current process and scope

SIPOC Tool

34

Start point: [insert your

own text]

Process Name: [Identify the process to be worked on]

Process Owner: [Confirm the process owner]

End point: [insert your

own text]

Insert the

suppliers to the

process

Suppliers Inputs Outputs Customers

Process

Insert inputs

provided by

suppliers

Insert tangible

outputs

Insert the

customers of the

process

List what are the necessary

requirements for process

Process Requirements

List what is critical to customer

Customer Requirements

Insert your own text

Insert your own text

Insert your own text

Insert your own text

Insert your own text

In scope

Out of scope

Tutorial

There should be no more than 5-7 high-level

process steps

Outputs should be tangible

There may be many inputs into the process but

use only the vital ones that are used to create to

output](https://image.slidesharecdn.com/13-240912093714-3eec5ba2/85/13-_Lean_6_Sigma_Toolkit_-_Overview_and_Approach-pptx-34-320.jpg)

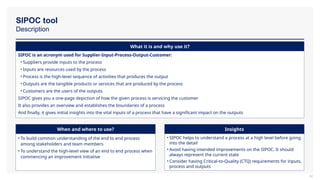

![High-level current process and scope

SIPOC Tool

35

Start point: the shop

orders coffee bean

Process Name: [Identify the process to be worked on]

Process Owner: [Confirm the process owner]

End point: The

customer drinks her

coffee

Coffee bean

supplier

Suppliers Inputs Outputs Customers

Process

Roasted coffee

beans

Milk

Water

Syrup

Cups

Lids

Espresso

Latte

Cappuccino

Mocha

Americano

Hot chocolate

In-store

customers

Drive-thru

customers

All the inputs have been received on

time and in the right quantity

Process Requirements

Quality coffee beverages that taste

good

Quick and efficient service

Friendly and helpful customer service

Customer Requirements

Grind coffee beans

Brew coffee

Steam milk

Mix coffee, milk, and syrup

Pour into cups

In scope

Out of scope

Real-life example for

a coffee shop

Add lids](https://image.slidesharecdn.com/13-240912093714-3eec5ba2/85/13-_Lean_6_Sigma_Toolkit_-_Overview_and_Approach-pptx-35-320.jpg)

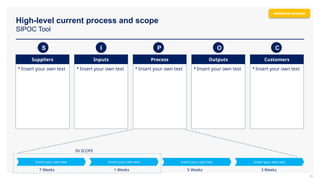

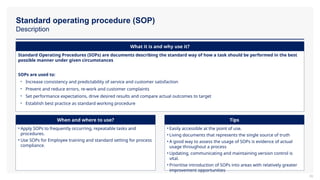

![Standard Operating Procedure (SOP)

Procedure Name: [Insert your own text]

Owner: [Insert your own text]

Version: [Insert your own text]

40

Responsibilities

[insert your own text]

Purpose

[insert your own text]

Scope

[insert your own text]

Procedure

1. [insert your own text]

• [insert your own text]

• [insert your own text]

• [insert your own text]

2. [insert your own text]

• [insert your own text]

• [insert your own text]

• [insert your own text]

3. [insert your own text]

• [insert your own text]

• [insert your own text]

• [insert your own text]

Template](https://image.slidesharecdn.com/13-240912093714-3eec5ba2/85/13-_Lean_6_Sigma_Toolkit_-_Overview_and_Approach-pptx-40-320.jpg)