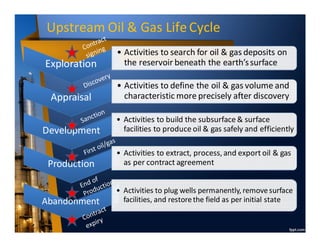

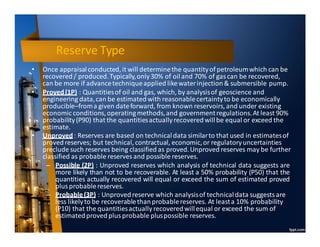

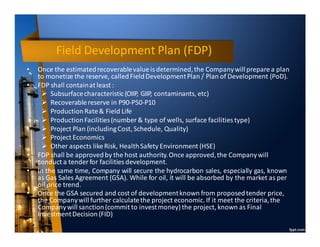

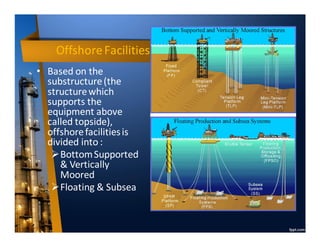

This document provides an overview of the oil and gas industry, including its upstream, midstream, and downstream sectors. It discusses how oil and gas are formed from the decomposition of ancient organisms, and traces the history of the industry from its early uses by ancient civilizations to the birth of the modern industry with Colonel Drake's 1859 well discovery. The document also outlines the key stages of the upstream oil and gas lifecycle from exploration and appraisal to development, production, and abandonment. It provides details on production facilities including wells, surface infrastructure, and different types of offshore facilities.