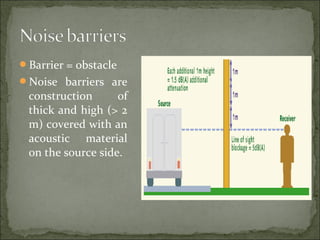

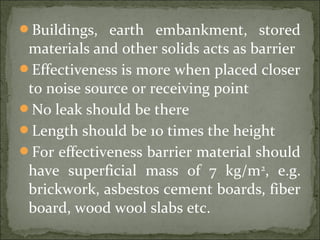

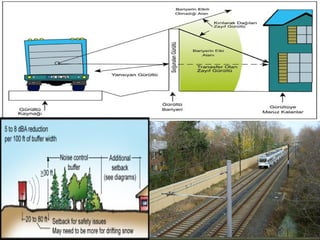

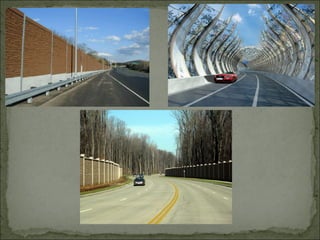

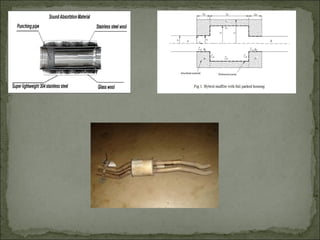

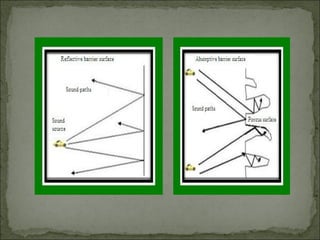

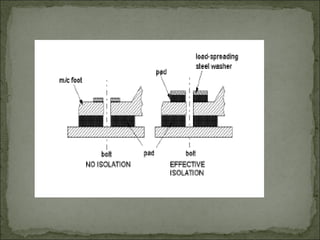

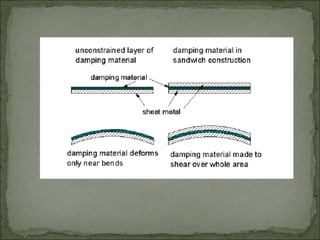

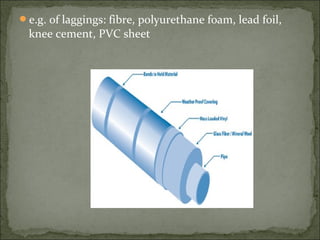

The document discusses various methods for noise control, including noise barriers that absorb or reflect sound, and mufflers (or silencers) that reduce noise through absorption and reflection principles. It emphasizes the importance of barrier height, length, and material for effective noise reduction, as well as vibration isolation techniques using low impedance materials. Damping methods, such as viscous and hysteresis damping, are also outlined to help control vibration and noise in mechanical systems.