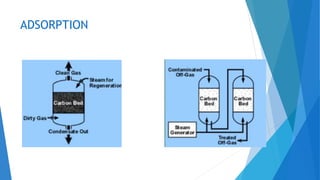

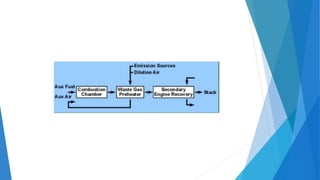

This document discusses various methods for air pollution control, including particulate and gas control systems. It describes common particulate control devices like cyclones, scrubbers, electrostatic precipitators, and baghouse filters. For gas control, it covers absorption, adsorption, and incineration methods. Absorption uses liquids to capture gases, while adsorption uses solids. Incineration involves combustion to convert gases to less harmful forms. The document provides details on the mechanisms and effectiveness of these different air pollution control methods.