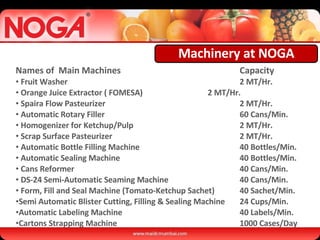

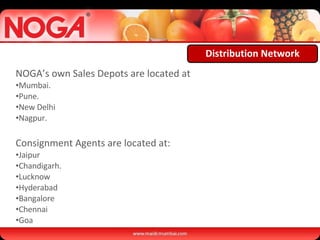

The document summarizes the history and operations of NOGA Private Limited, an agro-processing company in Maharashtra, India. It began as a cold storage facility for oranges in 1946 and was later taken over by the state government. NOGA processes various fruits into products like juices, squashes, jams and sells them to retail markets, hotels and airlines. It has received several awards for its products. NOGA continues to expand its product range and distribution network to meet growing demand.