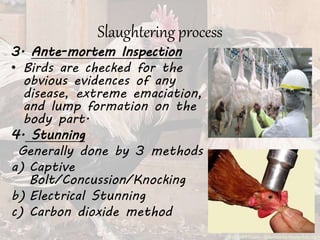

The document discusses the process of poultry processing from slaughtering to packaging. It begins by defining key terms like abattoir and carcass. It then describes the traditional and modern methods of slaughtering including steps like stunning, sticking, bleeding, scalding, picking and evisceration. After slaughtering, the processing steps discussed are chilling, grading, packaging and storage. The document also provides information on poultry meat properties, grading systems and popular chicken products. It concludes by noting that while India has a large poultry market, modern slaughter techniques have yet to be widely adopted.