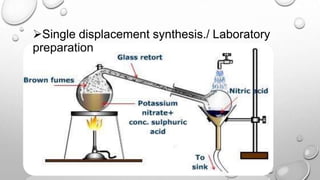

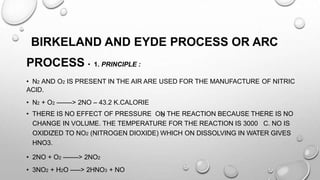

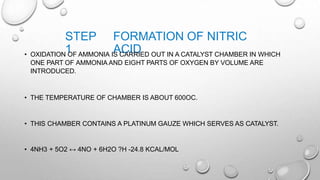

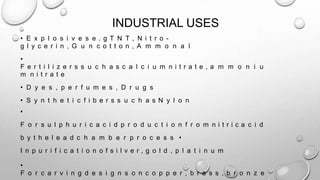

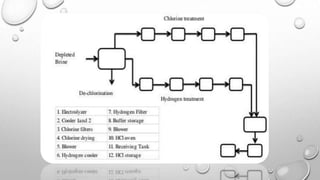

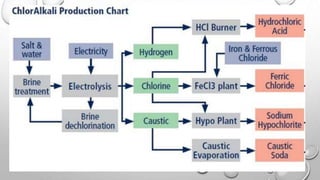

The document discusses the production and properties of nitric acid and hydrochloric acid. It describes the main industrial processes for manufacturing each acid, including the Ostwald process for nitric acid production and electrolysis of sodium chloride to produce chlorine for hydrochloric acid synthesis. Key safety considerations for acid storage are outlined, emphasizing the need for corrosion-resistant materials and segregation of different acid types.

![• ORIGINALLY POSTED BY ENGAGER

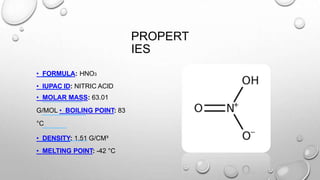

HIGHLY CONCENTRATED OR ANHYDROUS NITRIC ACID IS UNSTABLE AND DECOMPOSES SLOWLY

UNDER ORDINARY CONDITIONS, SEALS MUST NOT BE TIGHT BECAUSE DECOMPOSITION

PRODUCTS WILL GENERATE PRESSURE AND BOTTLE WILL FINALY CRACK AND SPILL ACID ALL

AROUND. HOWEVER THIS ACID CAN BE SAFELY STORED IN GLASS CONTAINER WITH TIGHT GLASS

LID IN DEEP FREEZE SECTION OF HOME REFRIGIRATOR. DECOMPOSITION IS SLOWED GREATLY AT

THIS CONDITIONS, AND NO2 GAS CANNOT GENERATE PRESSURE BECAUSE IT LIQUIFIES AT THIS

TEMPS. LIQUID NO2 REACTS WITH WATER CONTAMINANTS IN ACID TO FORM MORE NITRIC ACID,

SO SOME KIND OF CONSTANT EQUILIBRIUM EXIST. I STORED CONCENTRATED HNO3 IN THIS WAY

FOR MORE THEN 2 YEARS WITHOUT ANY PROBLEMS AND DEGREE OF DECOMPOSITION WAS LOW

(VERY SLIGHT YELLOW COLOR).

70% NITRIC ACID AND BELOW CAN BE STORED FOREVER IN DARK GLASS BOTTLES WITH PLASTIC

LID, WITHOUT ANY DECOMPOSITION AT ORDINARY TEMPERATURE.

[EDITED ON 15-7-2008 BY ENGAGER]](https://image.slidesharecdn.com/nitricacidpreparationuses-191221142107/85/Nitric-acid-preparation-uses-31-320.jpg)