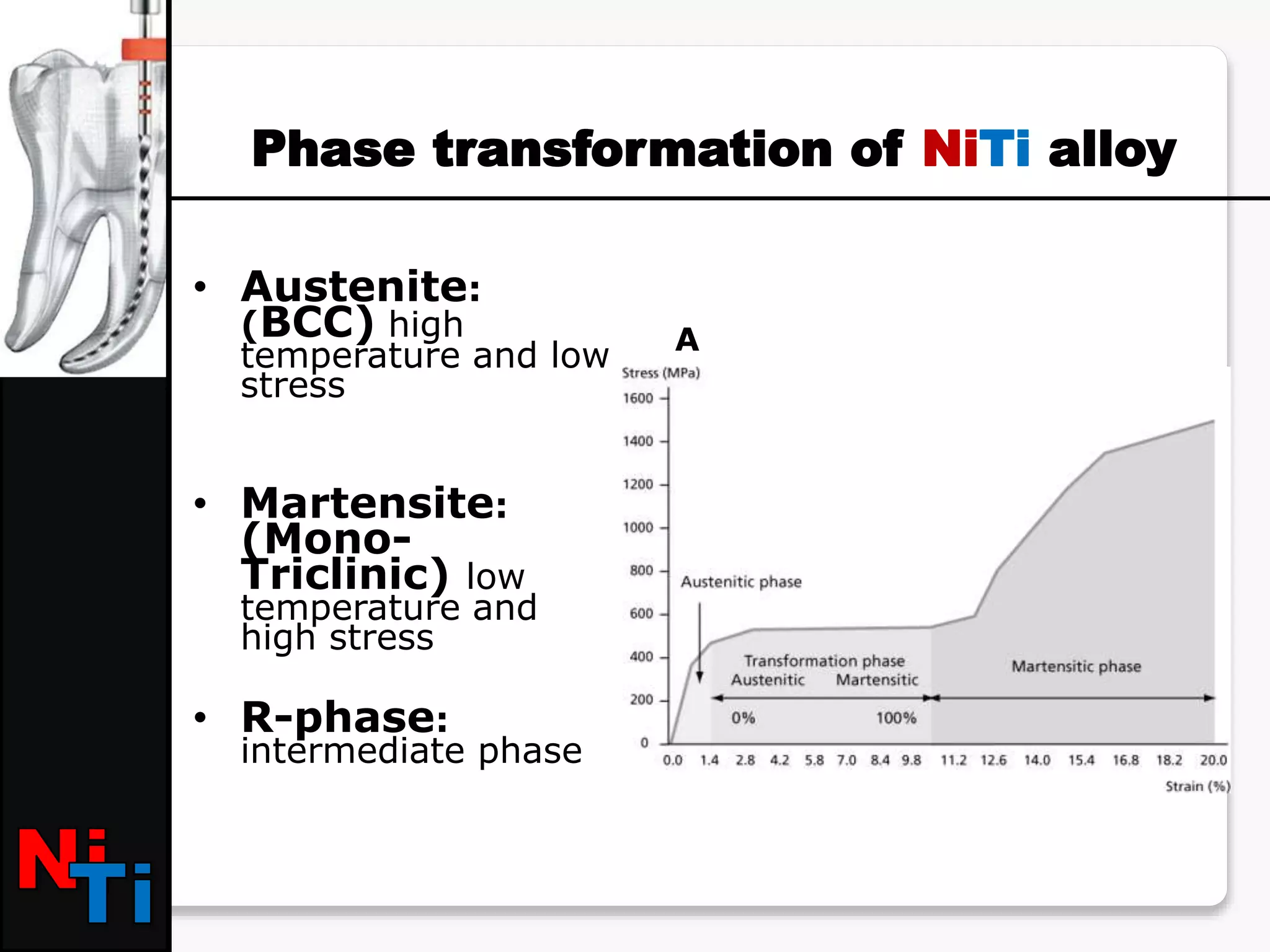

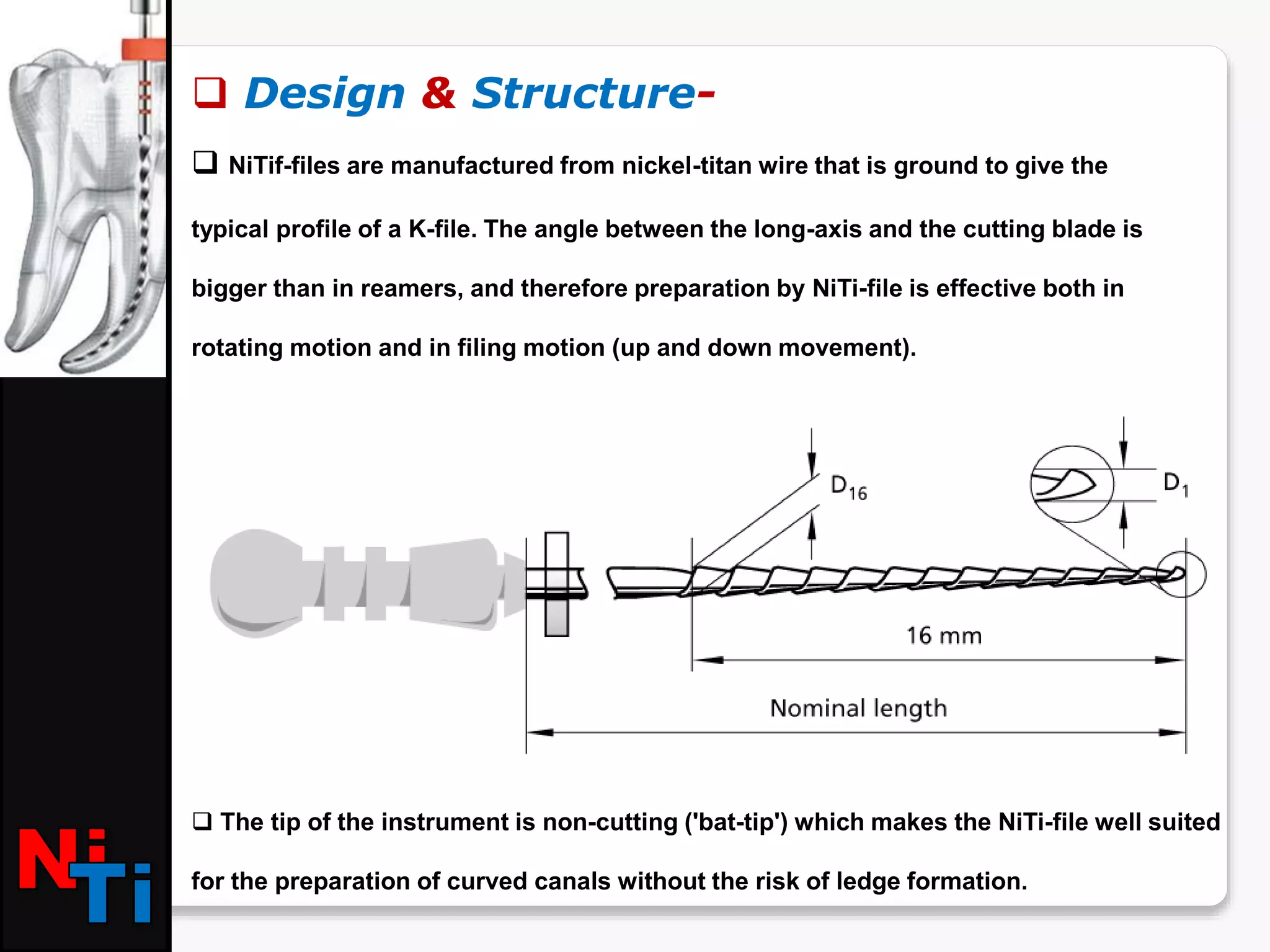

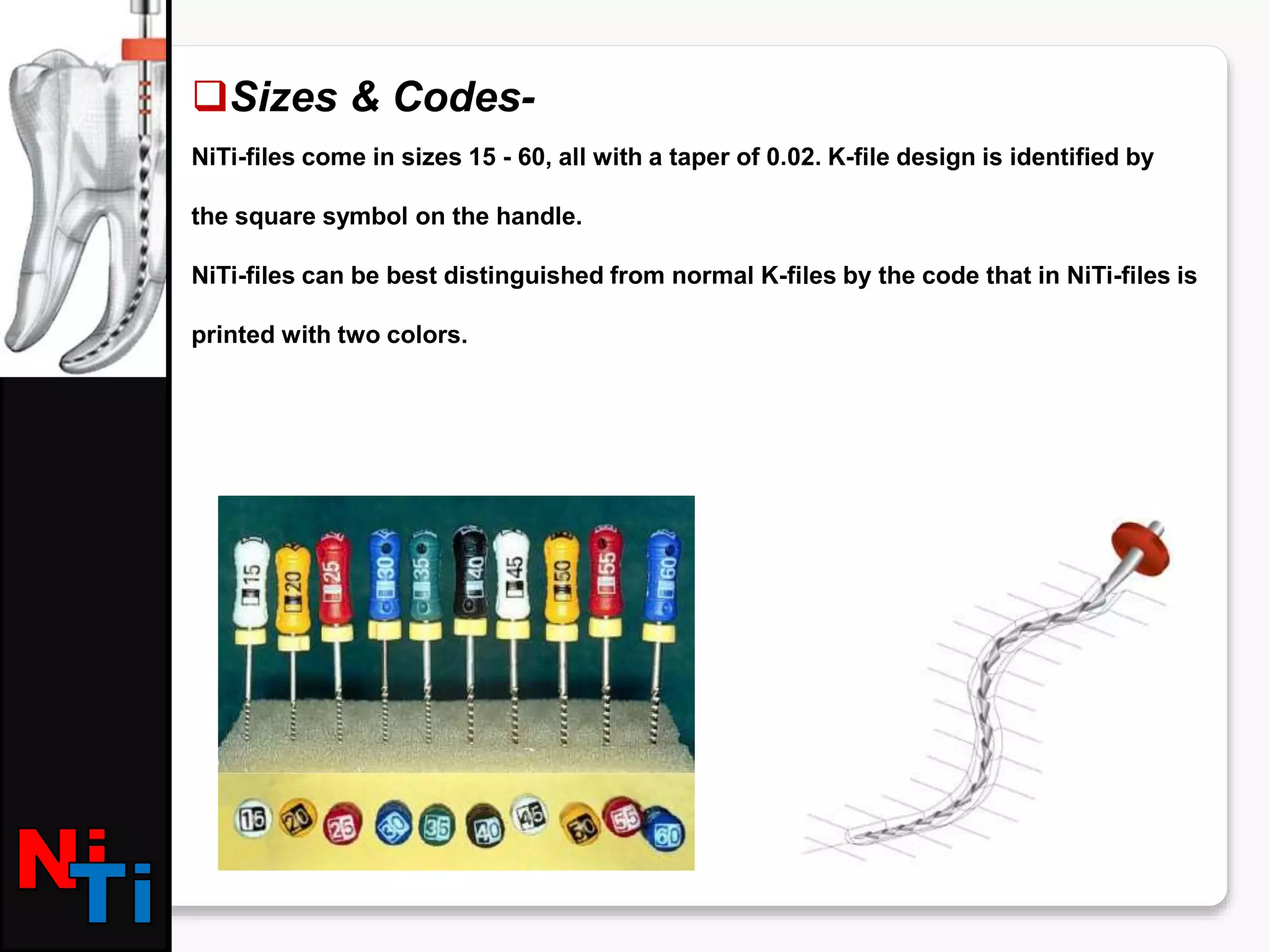

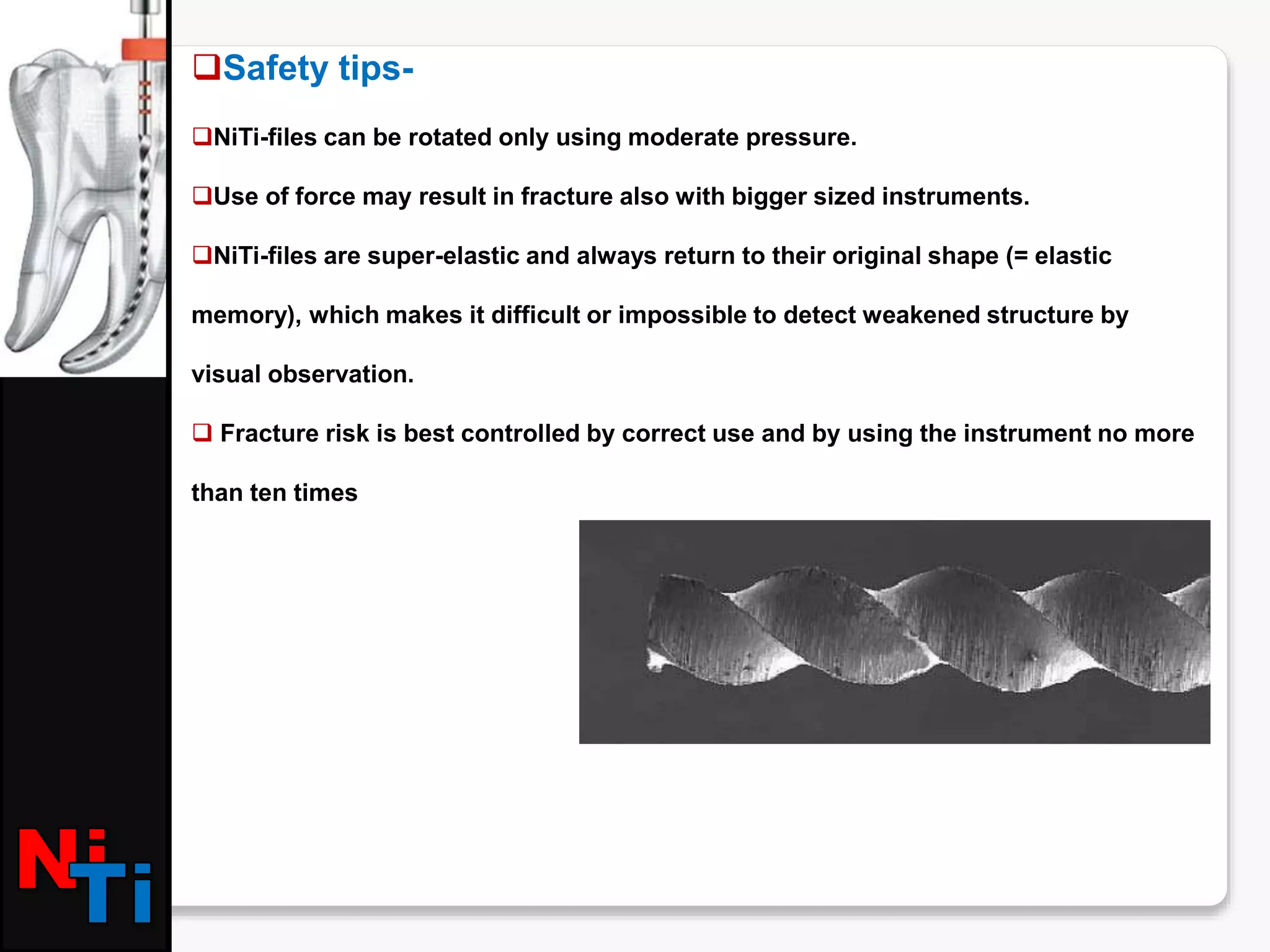

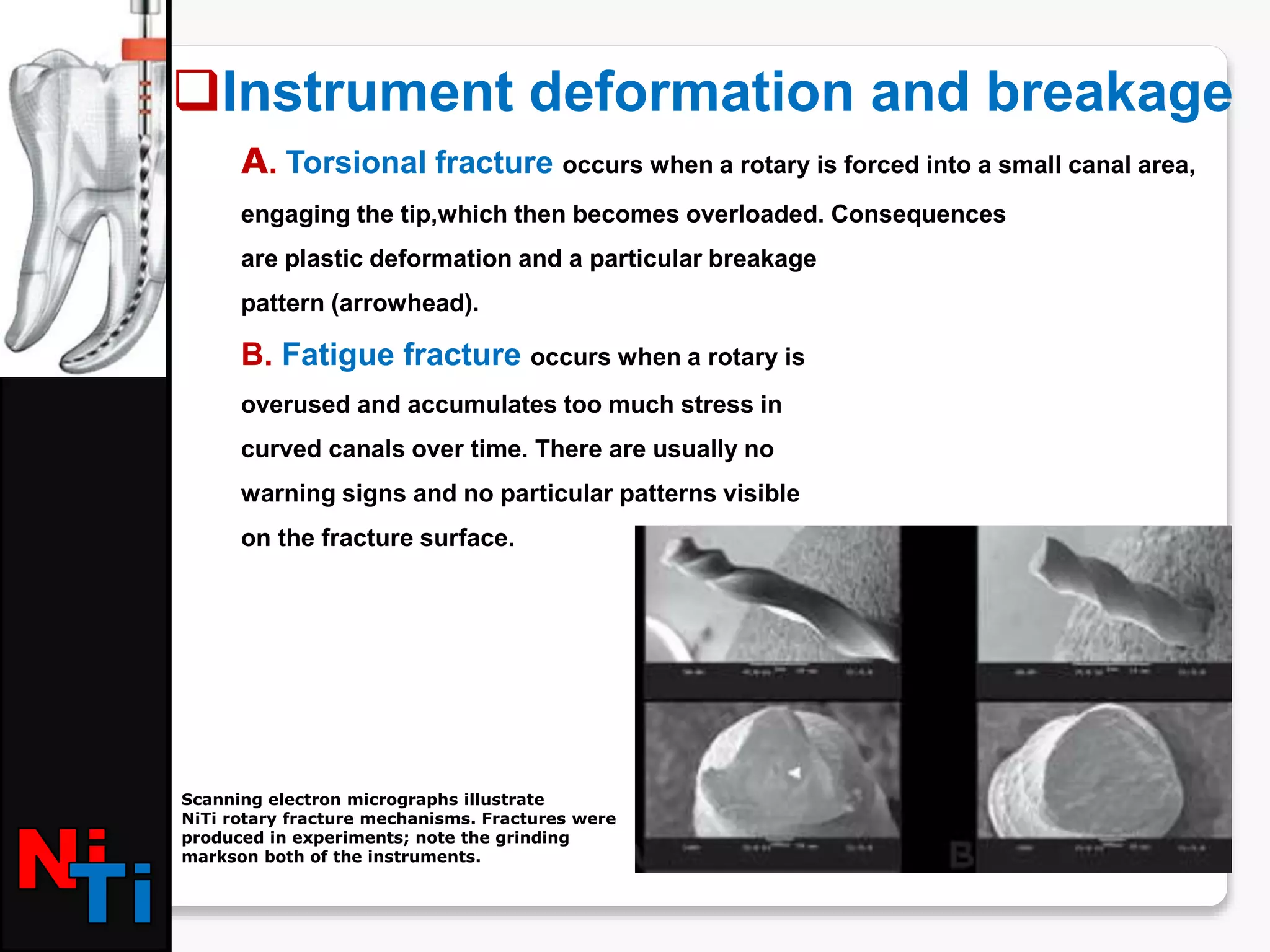

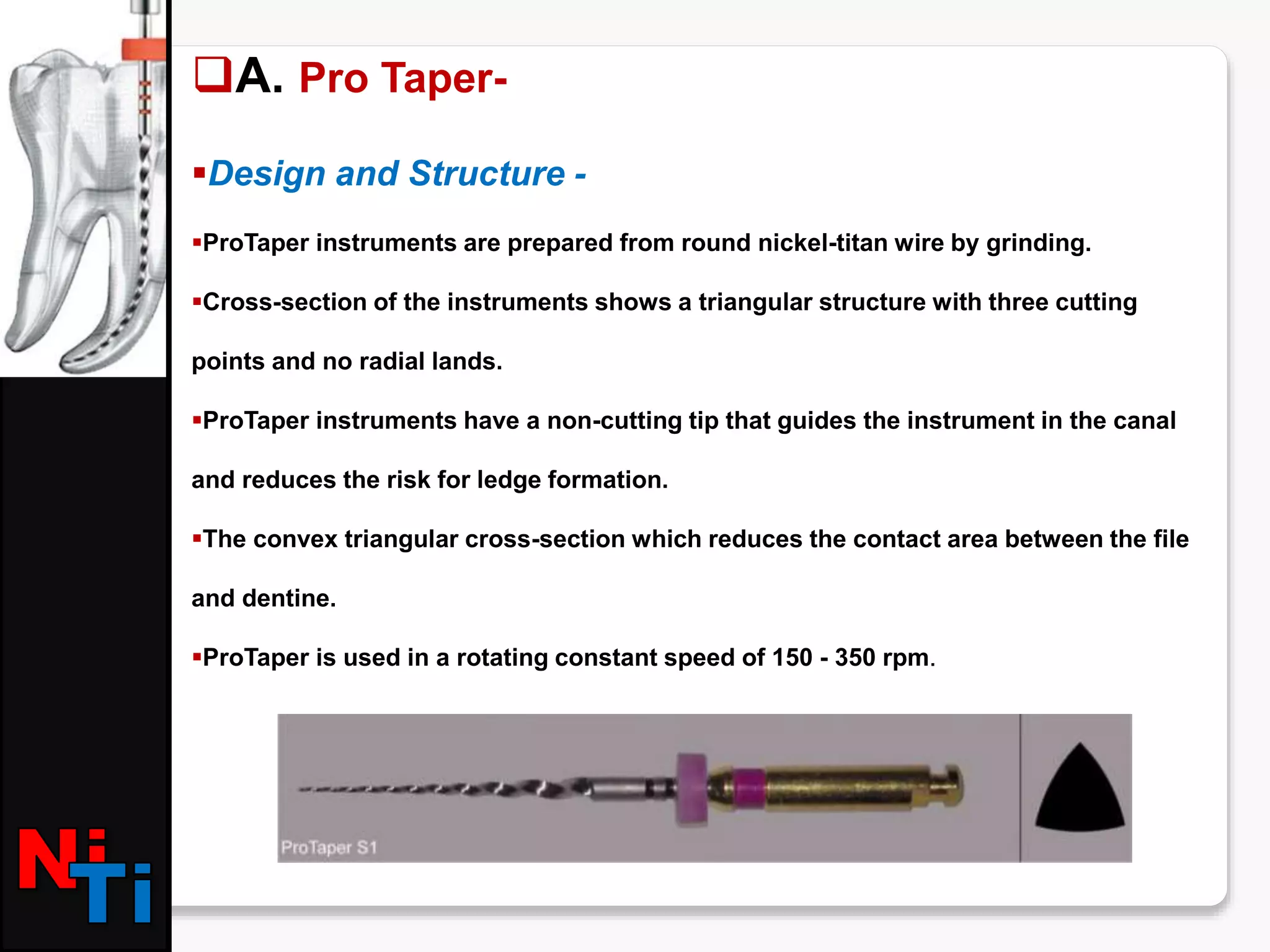

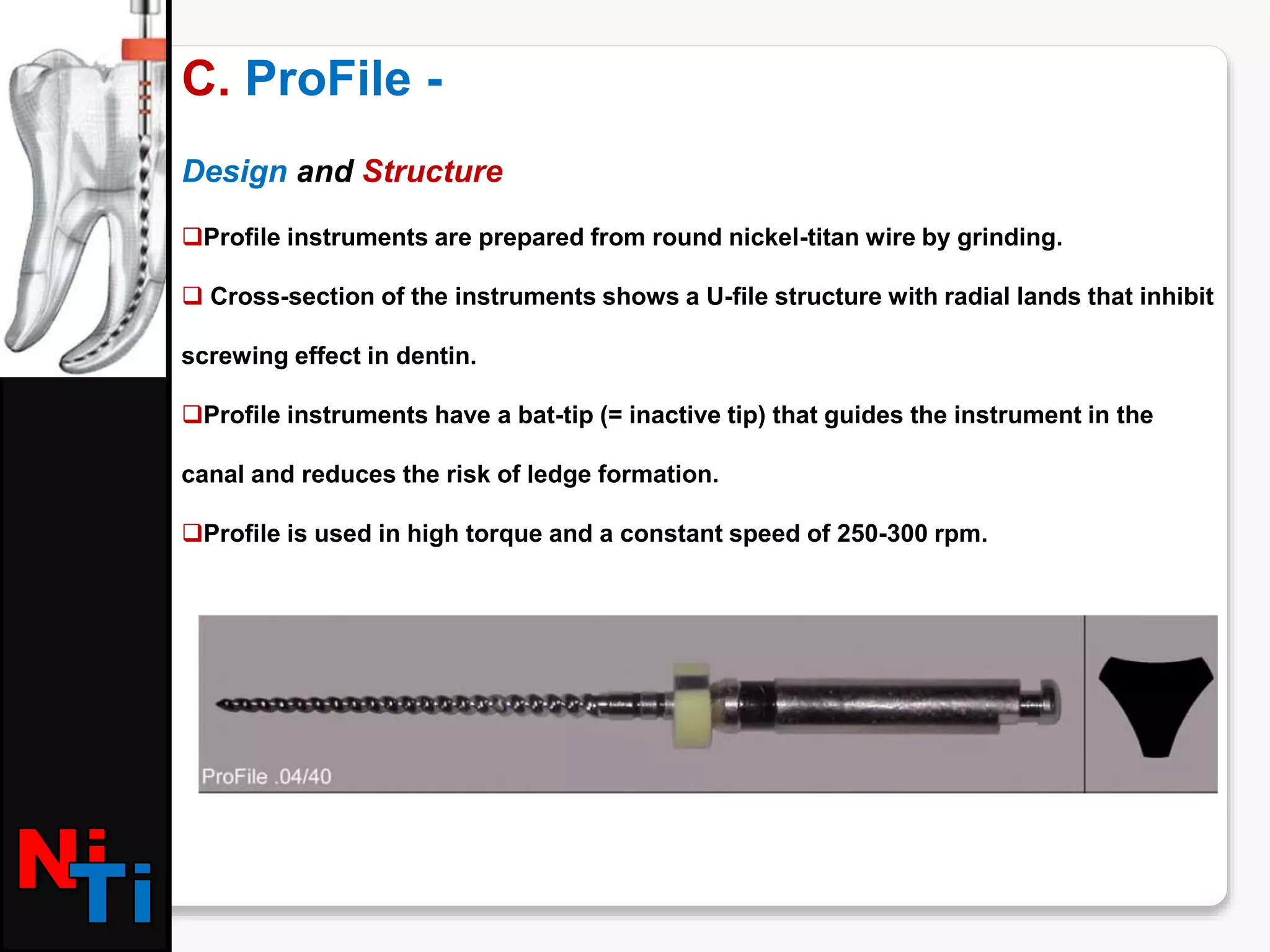

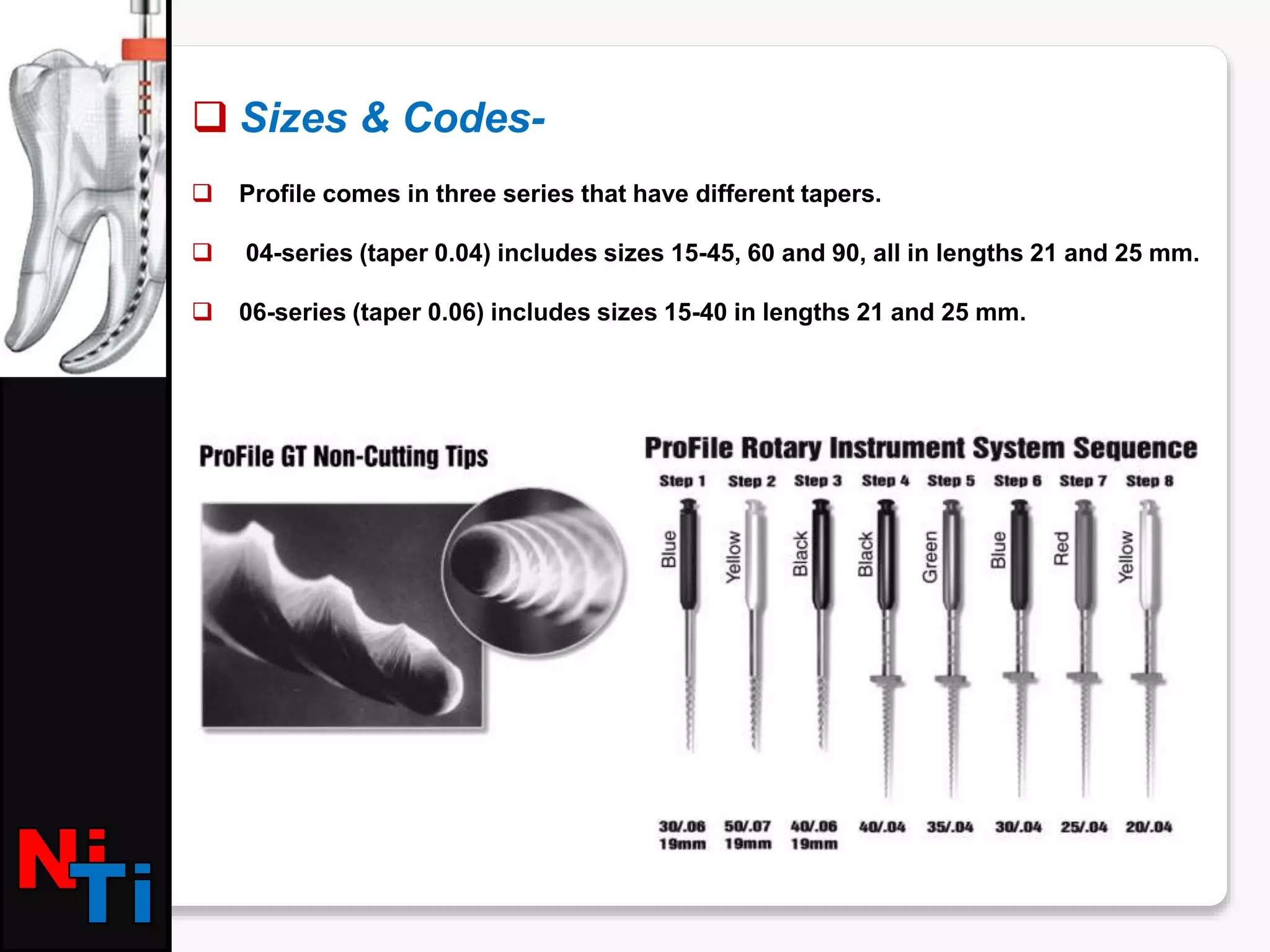

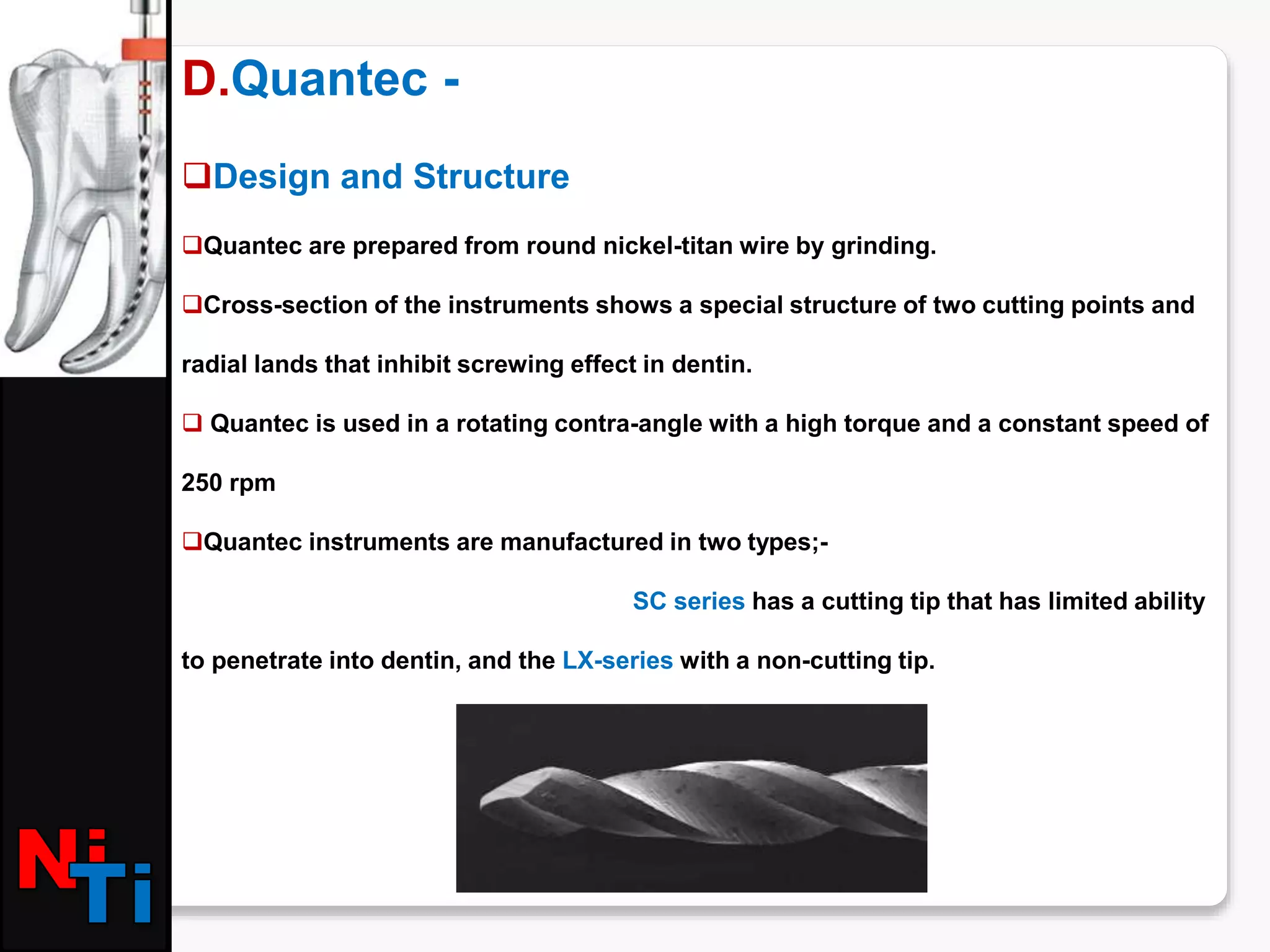

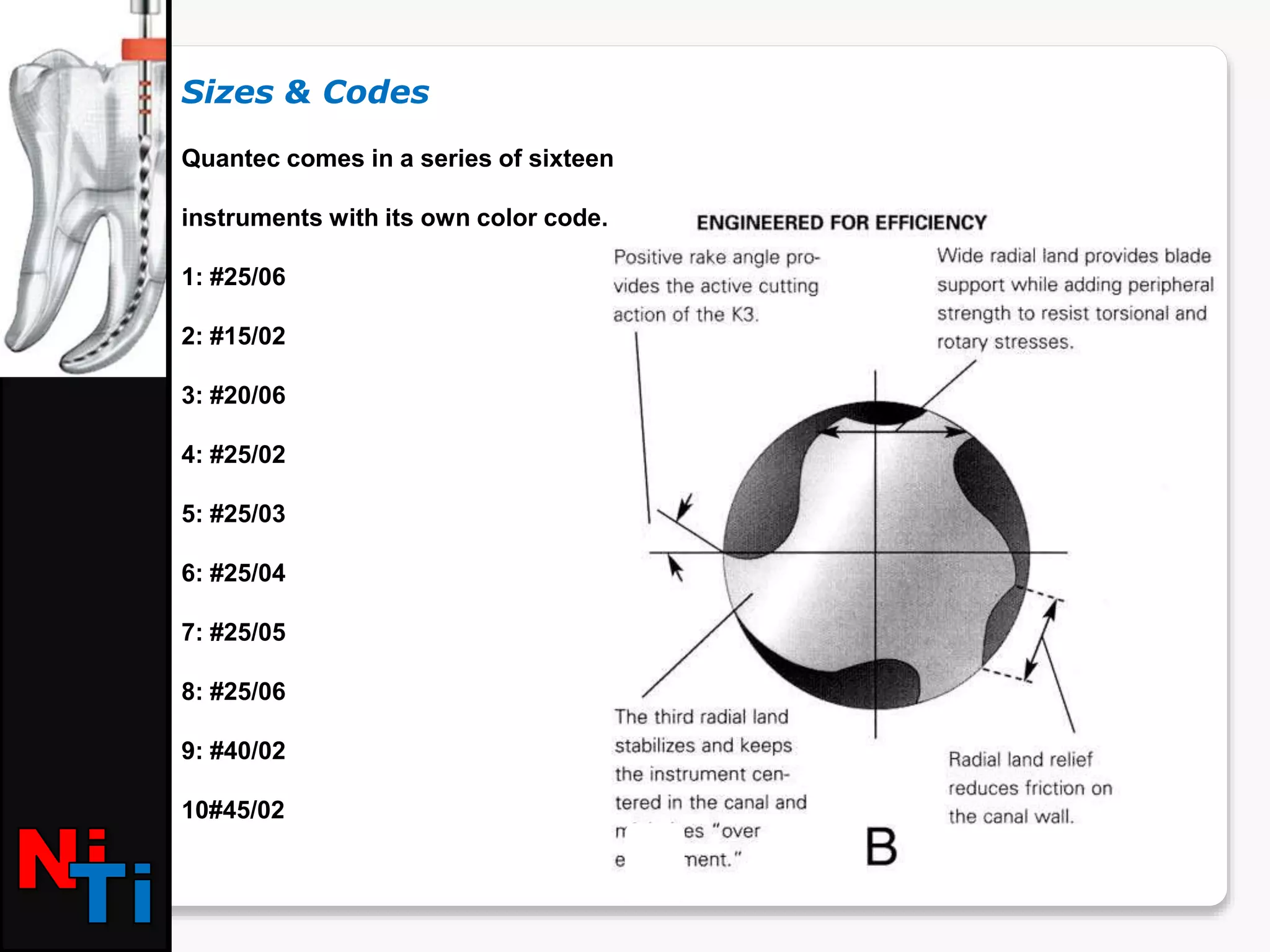

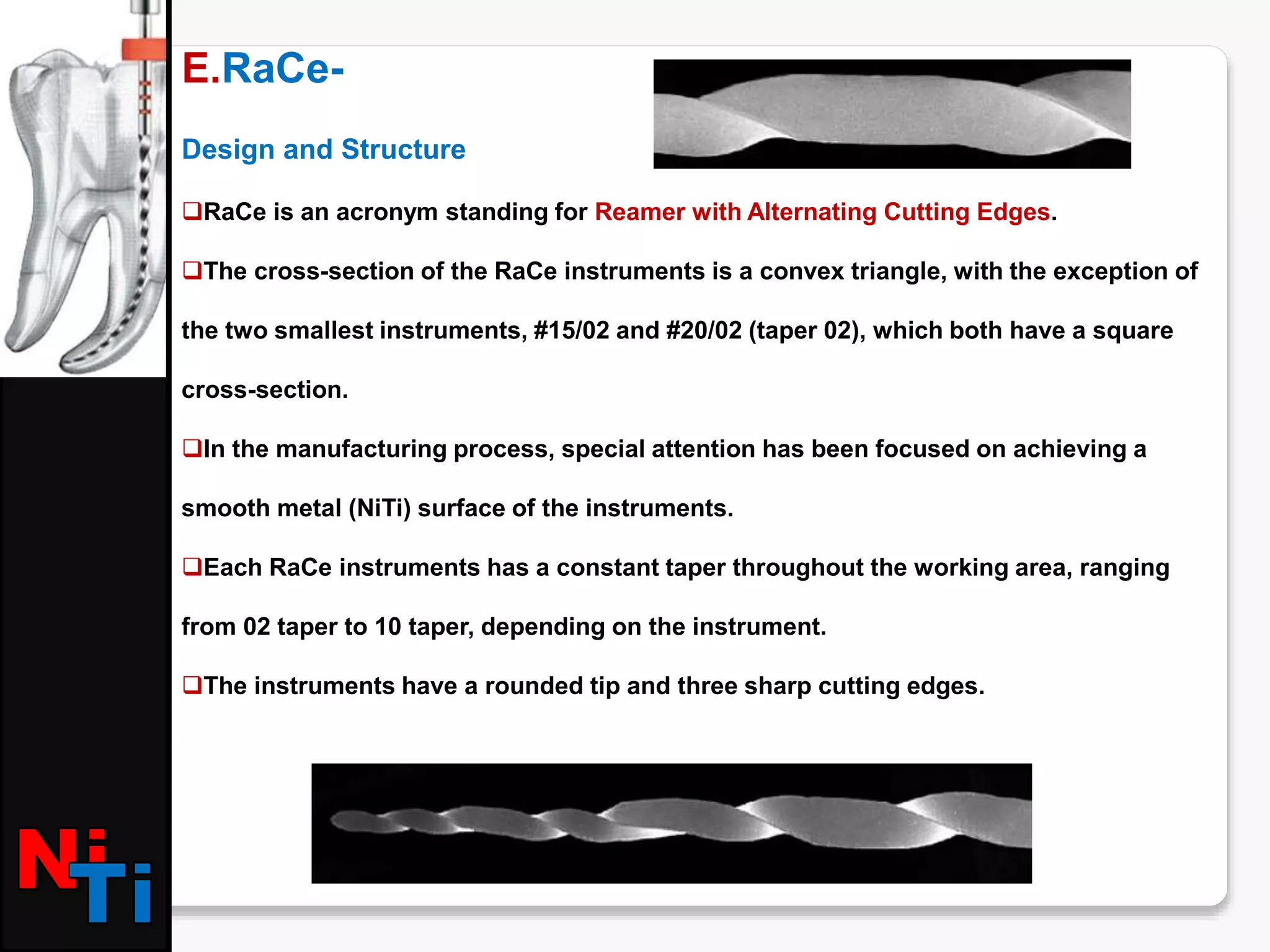

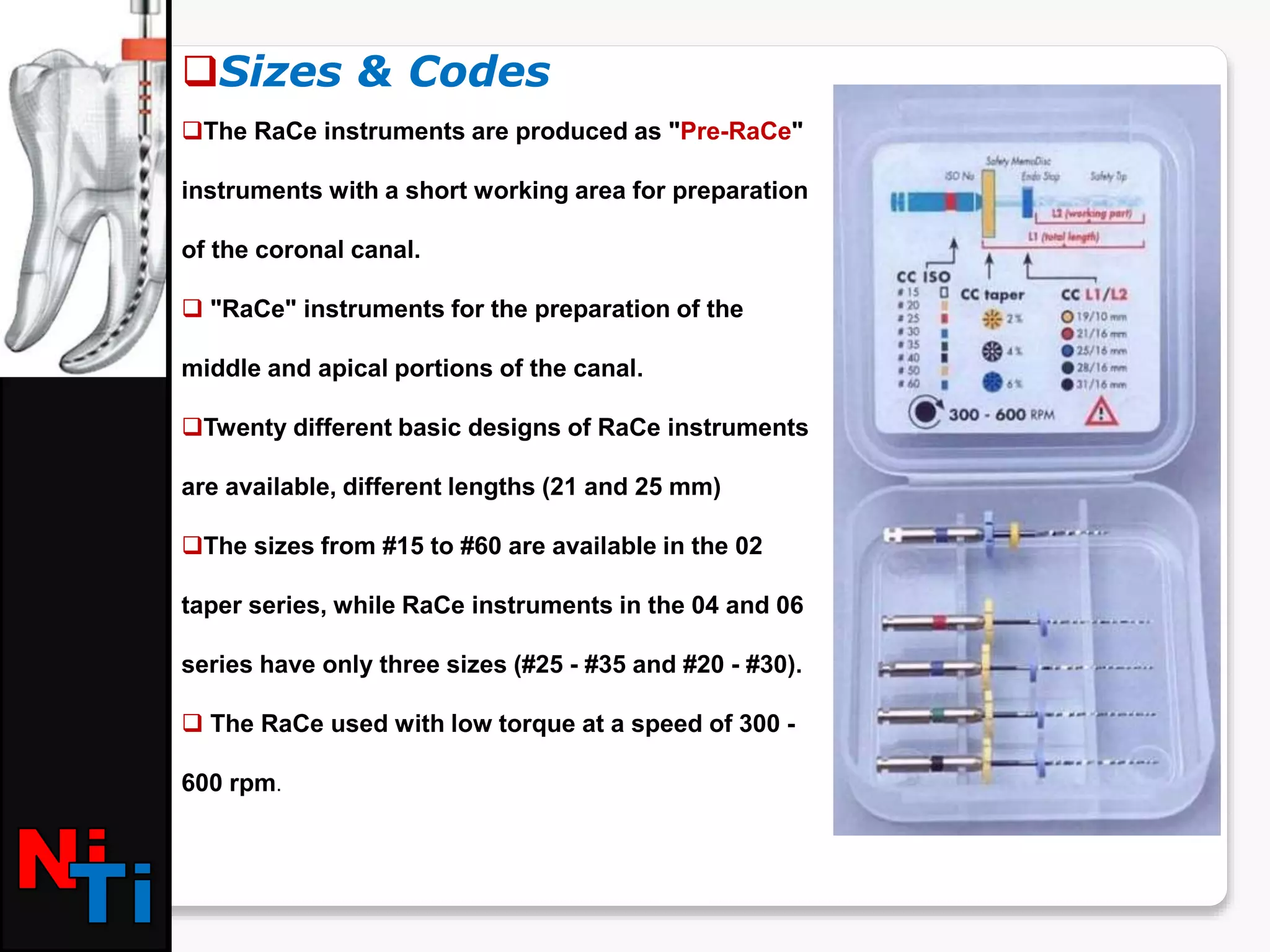

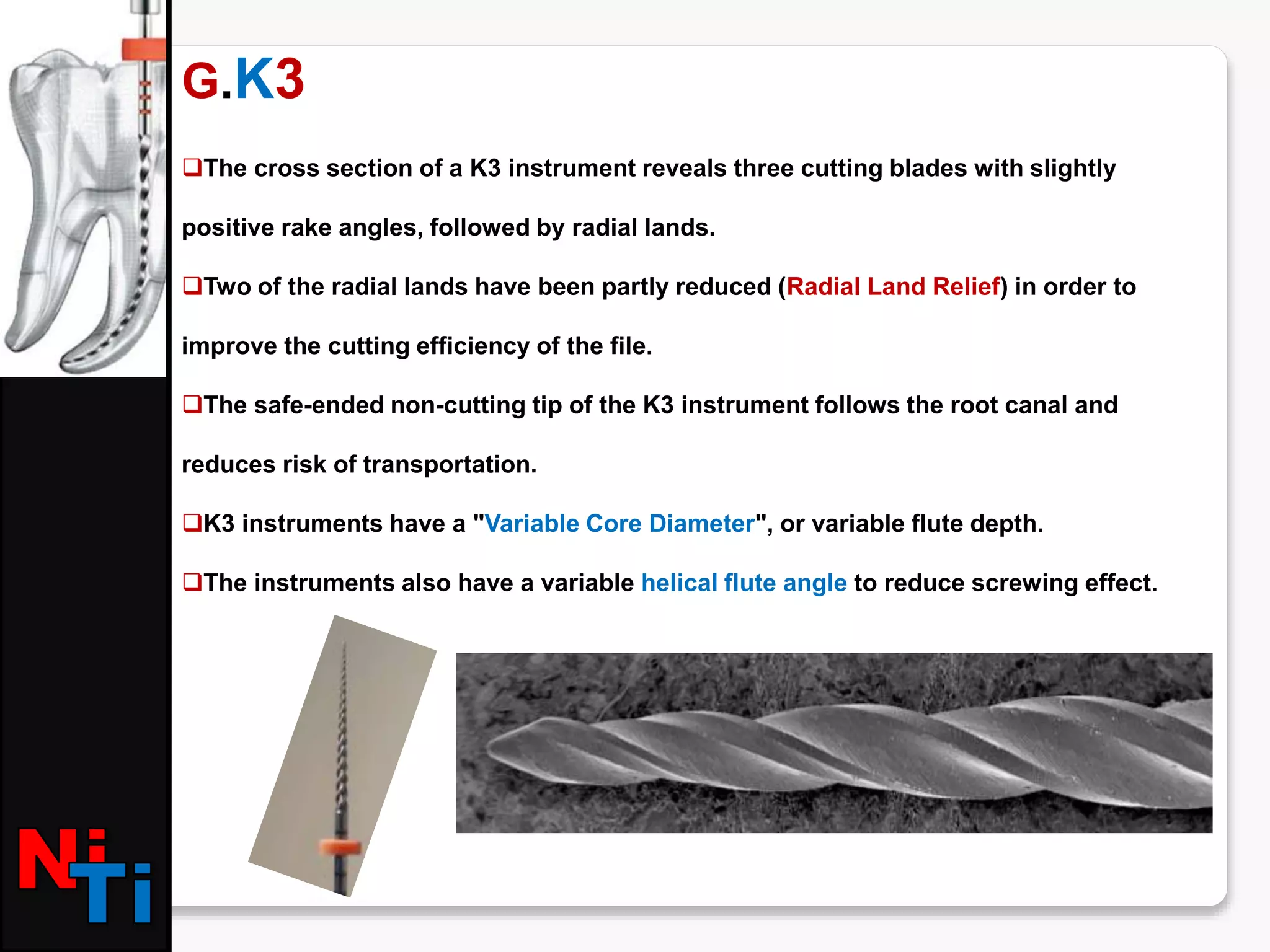

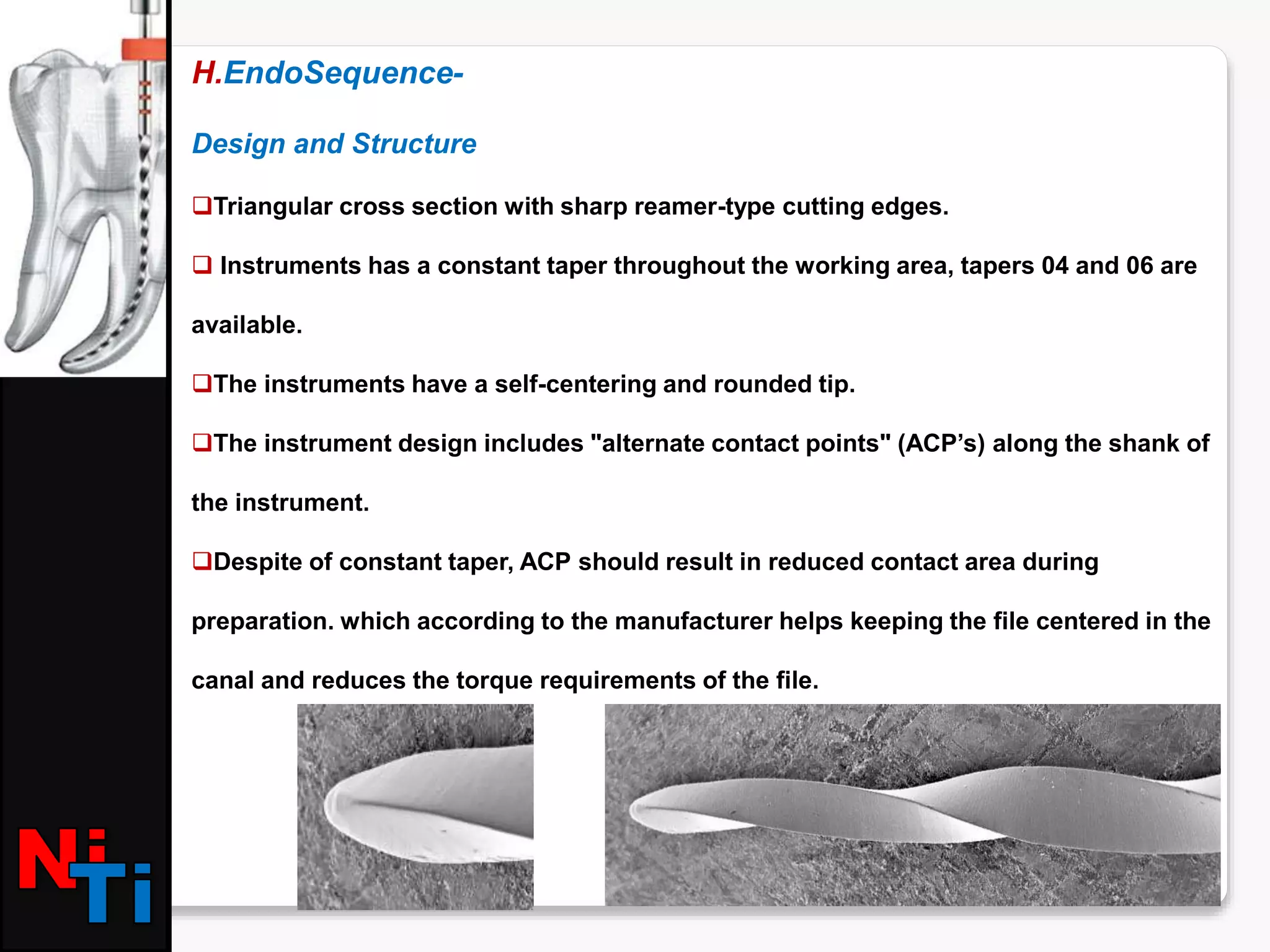

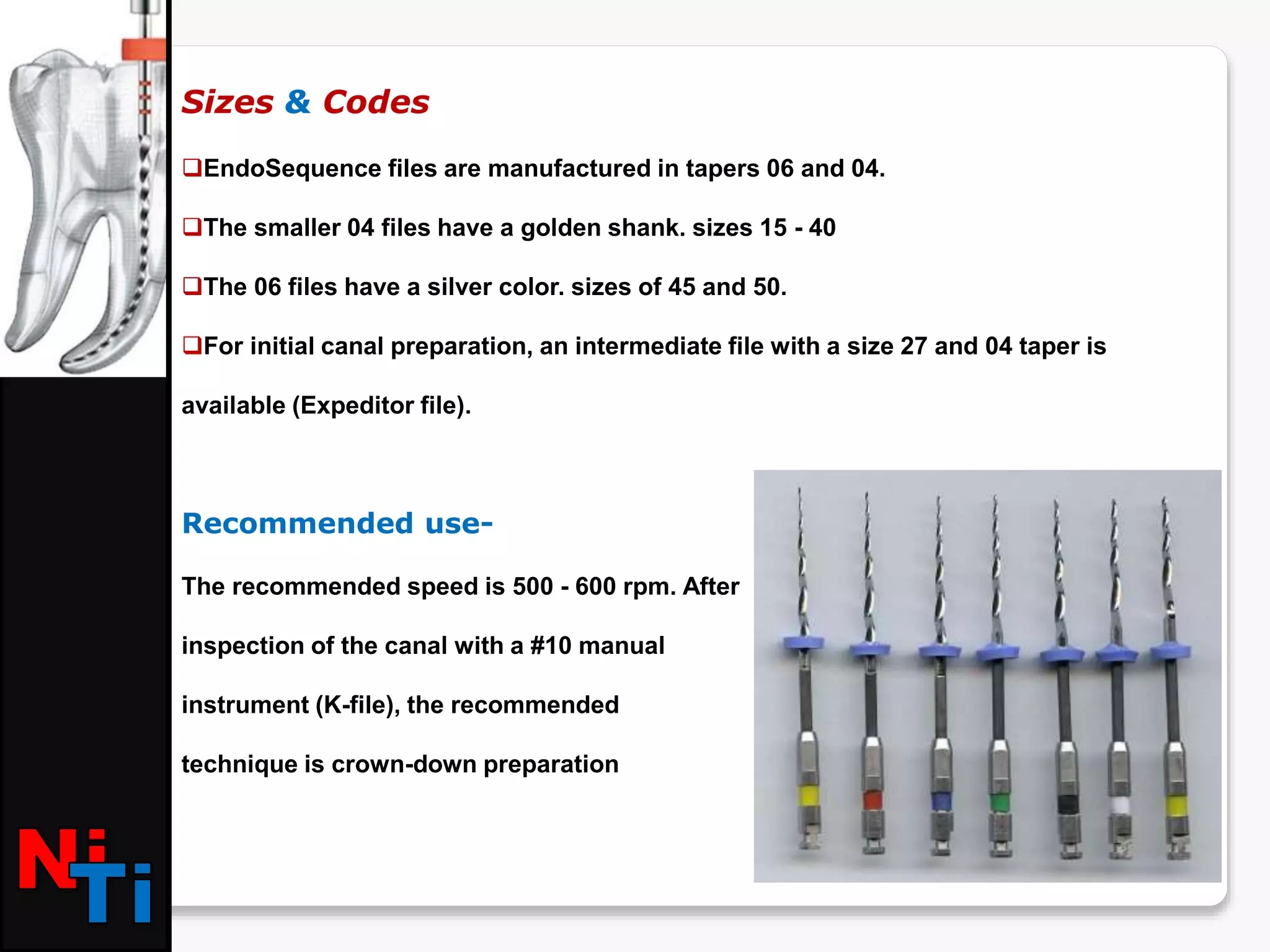

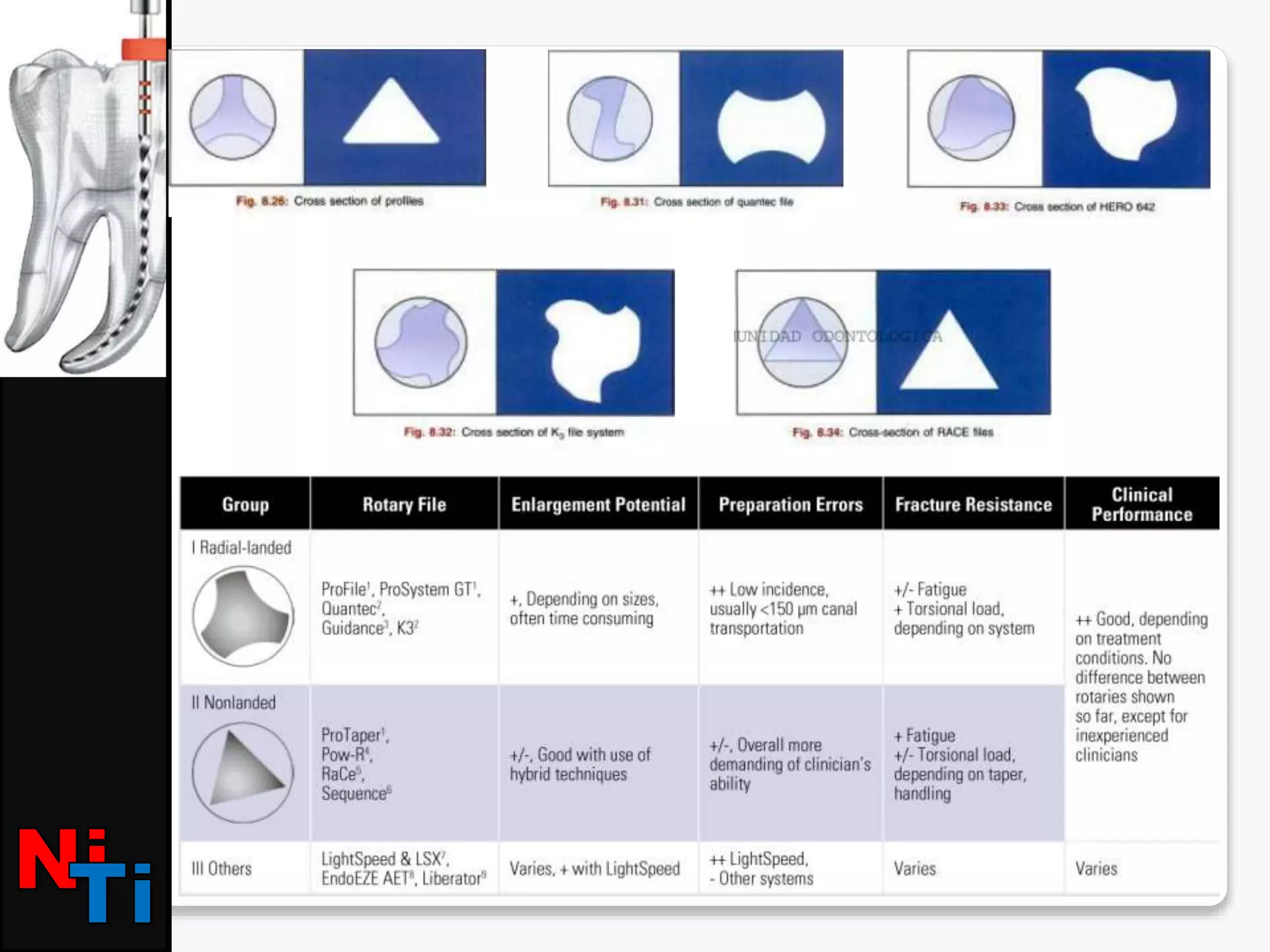

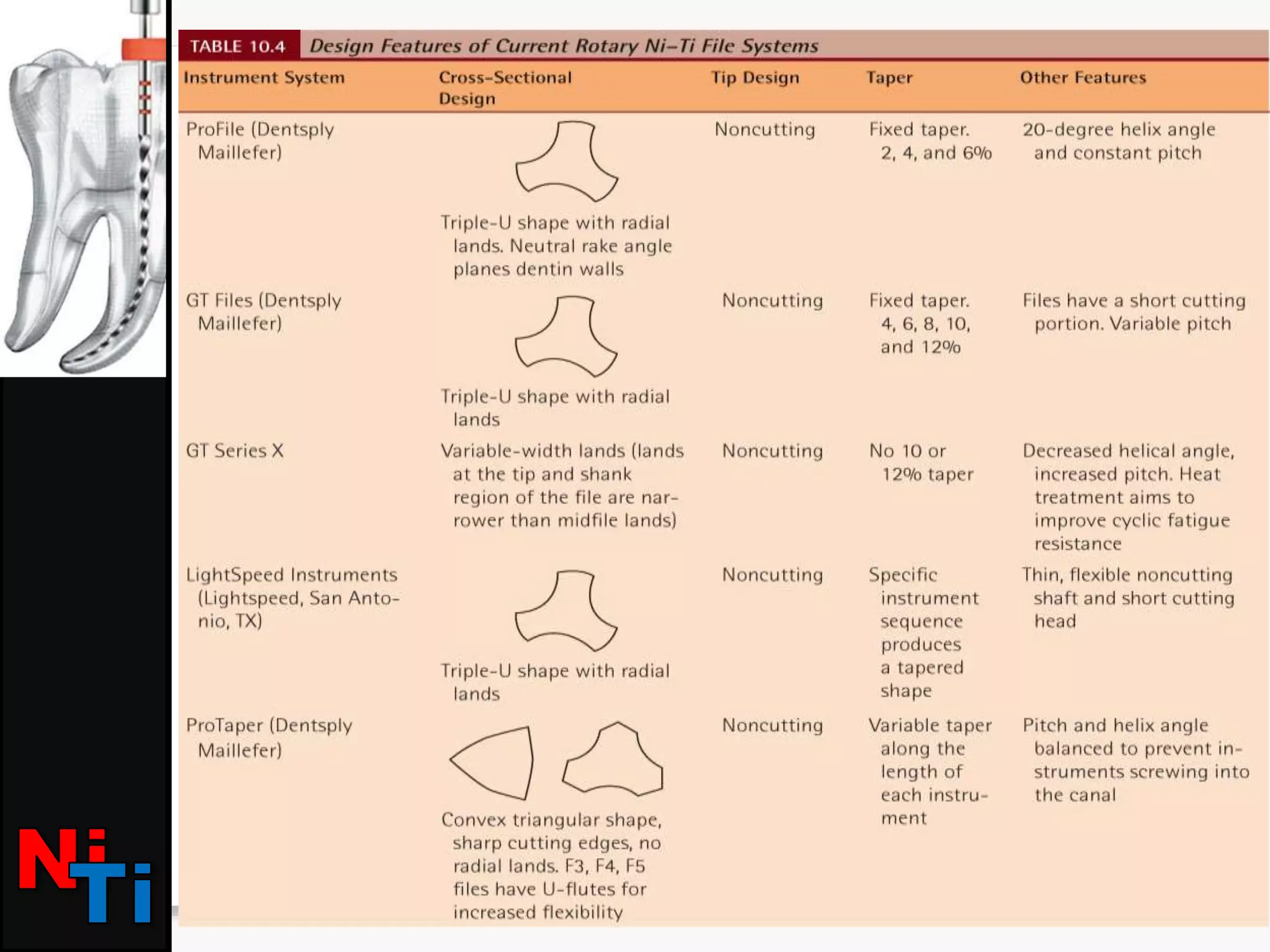

Nickel-titanium alloys are commonly used in endodontic instruments due to their shape memory and super elastic properties. This document discusses the composition and manufacturing of NiTi alloys. It then summarizes various NiTi file systems including ProTaper, Great Taper, ProFile, Quantec, RACE, K3, and EndoSequence, outlining their designs, sizes, tapers and recommended usage. Safety tips are provided for using NiTi files to avoid fractures which can be difficult to detect visually due to the alloy's elastic memory.