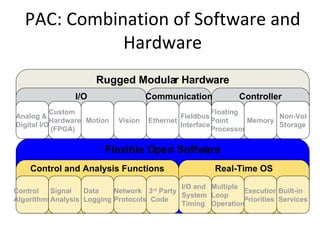

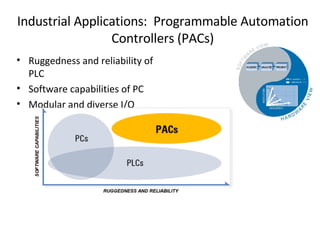

The document discusses National Instruments' CompactRIO system, a reconfigurable input/output system for industrial control applications. It consists of a real-time controller running LabVIEW that can be paired with modular I/O modules. CompactRIO offers benefits like ruggedness, flexibility, and ease of programming compared to traditional PLC or PC-based systems. Specific modules mentioned include analog input, digital I/O, and thermocouple modules. CompactRIO is targeted at applications requiring control, measurement, processing or communication capabilities.