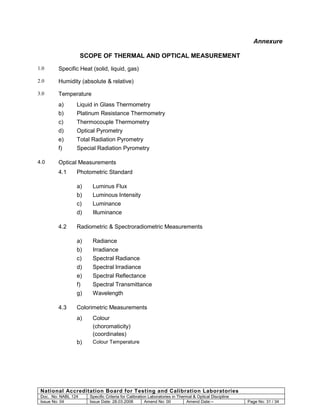

This document provides guidelines for calibration laboratories seeking accreditation for thermal and optical measurements. It discusses the organization, management system, personnel, facilities, equipment, measurement traceability, and other general requirements for laboratories. The document has three parts: Part I discusses general requirements, Part II provides specific criteria for different thermal and optical parameters, and Part III gives guidelines on measurement uncertainties for various standard accuracies.