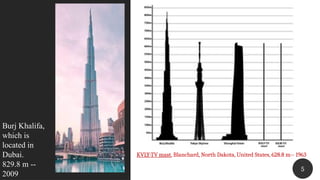

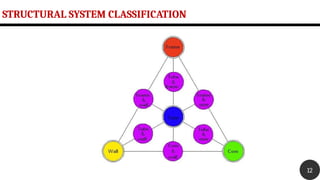

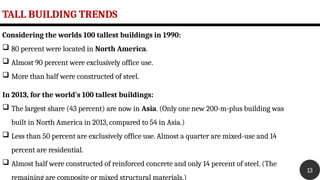

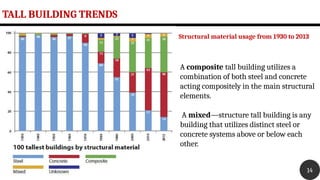

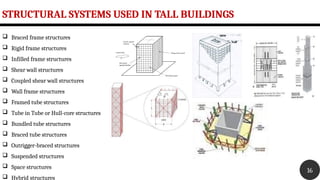

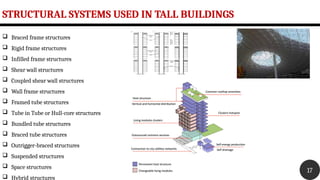

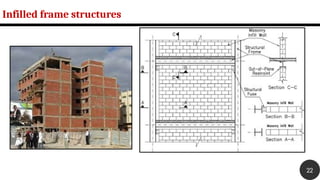

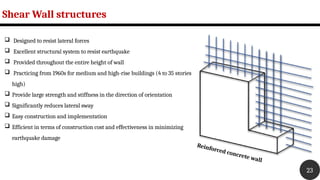

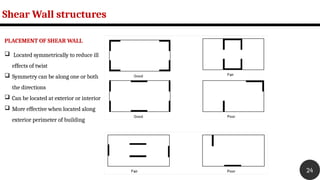

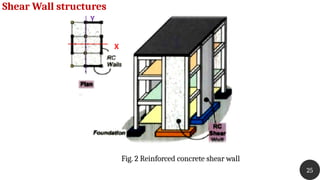

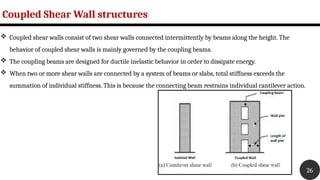

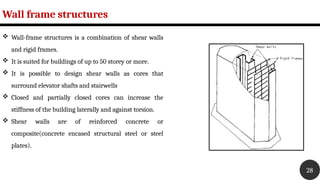

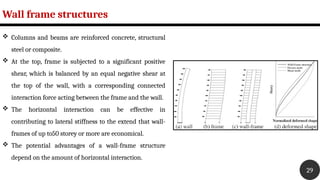

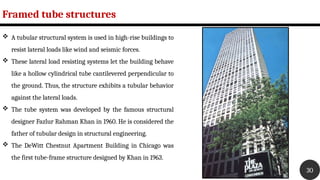

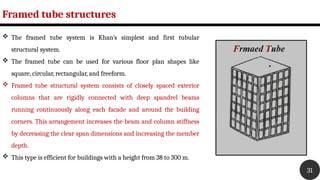

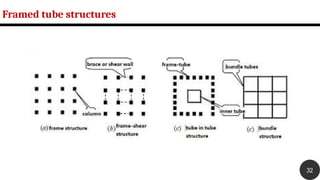

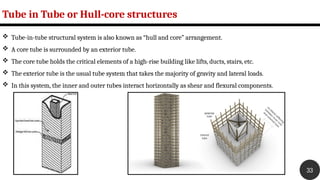

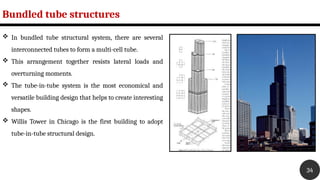

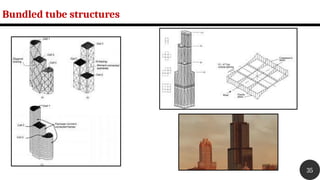

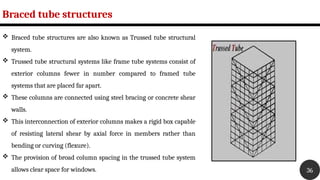

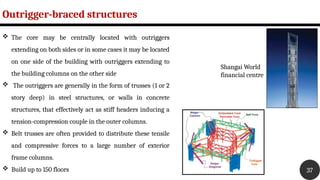

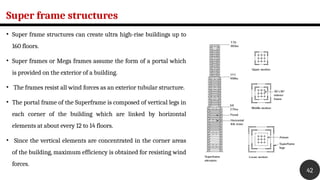

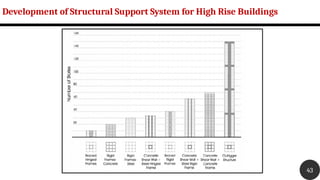

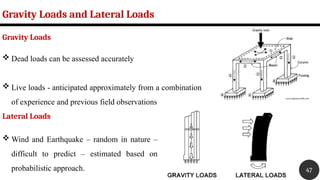

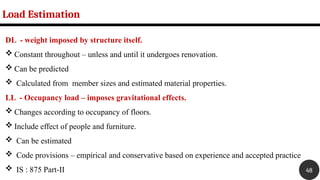

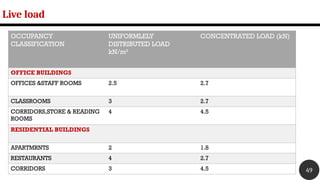

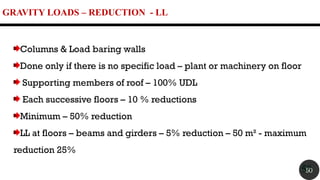

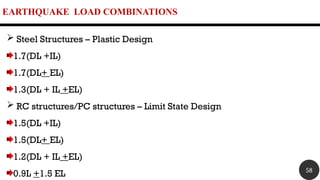

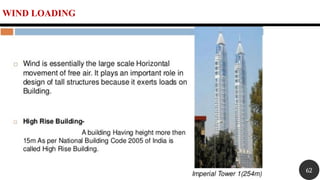

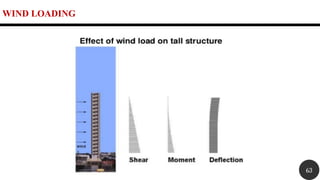

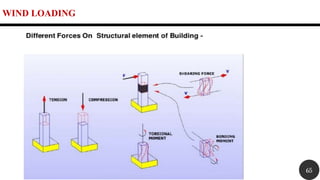

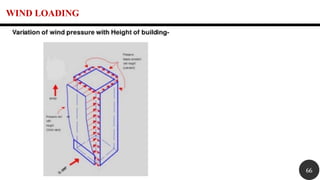

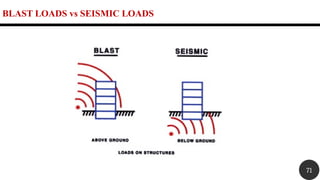

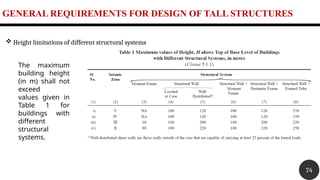

The document provides an overview of tall buildings and their structural systems, defining tall buildings and discussing trends in high-rise construction due to urban land scarcity and economic growth. It details the evolution of structural systems from historical to modern techniques, highlighting various types of structural systems such as braced frames, shear walls, and composite structures. Additionally, it covers loads acting on tall structures, emphasizing the importance of wind and seismic loads in their design.