This document describes an MRP and inventory performance management system implemented at a valve manufacturing company. The 11-slide presentation covers the following key points:

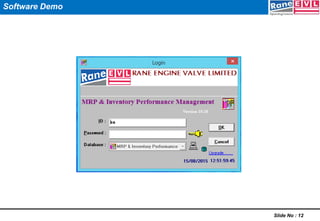

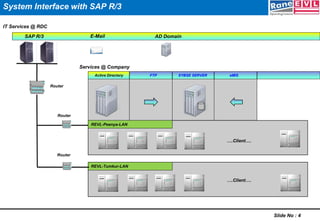

1. The system interfaces with various SAP modules to improve planning and inventory processes across functions like production, materials, and marketing.

2. Major automated processes enabled by the system include production planning/scheduling, inventory analysis, scrap analysis, and sales forecast integration.

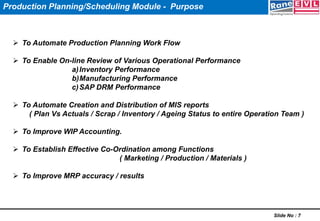

3. A demonstration of the production planning/scheduling module shows benefits like improved visibility, inventory control, and coordination between departments.

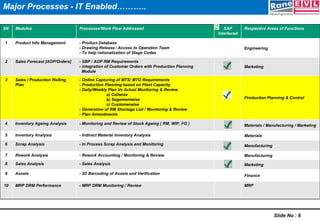

![Slide No : 5

SN Modules Processes/Work Flow Addressed SAP

Interfaced

Respective Areas of Functions

1 Product Info Management - Product Database

- Drawing Release / Access to Operation Team

- To help rationalization of Stage Codes

Engineering

2 Sales Forecast [AOP/Orders] - SBP / AOP RM Requirements

- Integration of Customer Orders with Production Planning

Module

Marketing

3 Sales / Production Rolling

Plan

- Online Capturing of MTS/ MTO Requirements

- Production Planning based on Plant Capacity

- Daily/Weekly Plan Vs Actual Monitoring & Review

a) Cellwise

b) Segementwise

c) Customerwise

- Generation of RM Shortage List / Monitoring & Review

- Plan Amendments

Production Planning & Control

4 Inventory Ageing Analysis - Monitoring and Review of Stock Ageing ( RM, WIP, FG ) Materials / Manufacturing / Marketing

5 Inventory Analysis - Indirect Material Inventory Analysis Materials

6 Scrap Analysis - In Process Scrap Analysis and Monitoring Manufacturing

7 Rework Analysis - Rework Accounting / Monitoring & Review Manufacturing

8 Sales Analysis - Sales Analysis Marketing

9 Assets - 2D Barcoding of Assets and Verification

Finance

10 MRP DRM Performance - MRP DRM Monitoring / Review MRP

Major Process – IT Enabled…….](https://image.slidesharecdn.com/mrpinvent-170115090446/85/MRP-Inventory-Performance-Management-5-320.jpg)

![Slide No : 6

SN Modules Processes/Work Flow Addressed SAP

Interfaced

Respective Areas of Functions

1 Product Info Management - Product Database

- Drawing Release / Access to Operation Team

- To help rationalization of Stage Codes

Engineering

2 Sales Forecast [AOP/Orders] - SBP / AOP RM Requirements

- Integration of Customer Orders with Production Planning

Module

Marketing

3 Sales / Production Rolling

Plan

- Online Capturing of MTS/ MTO Requirements

- Production Planning based on Plant Capacity

- Daily/Weekly Plan Vs Actual Monitoring & Review

a) Cellwise

b) Segementwise

c) Customerwise

- Generation of RM Shortage List / Monitoring & Review

- Plan Amendments

Production Planning & Control

4 Inventory Ageing Analysis - Monitoring and Review of Stock Ageing ( RM, WIP, FG ) Materials / Manufacturing / Marketing

5 Inventory Analysis - Indirect Material Inventory Analysis Materials

6 Scrap Analysis - In Process Scrap Analysis and Monitoring Manufacturing

7 Rework Analysis - Rework Accounting / Monitoring & Review Manufacturing

8 Sales Analysis - Sales Analysis Marketing

9 Assets - 2D Barcoding of Assets and Verification

Finance

10 MRP DRM Performance - MRP DRM Monitoring / Review MRP

Major Processes - IT Enabled………..](https://image.slidesharecdn.com/mrpinvent-170115090446/85/MRP-Inventory-Performance-Management-6-320.jpg)