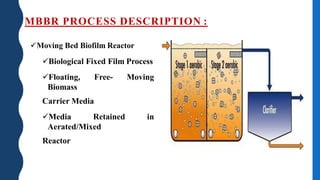

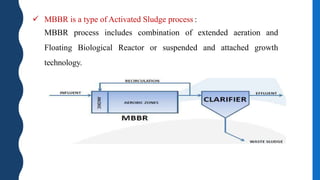

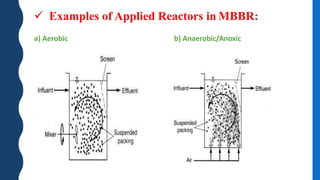

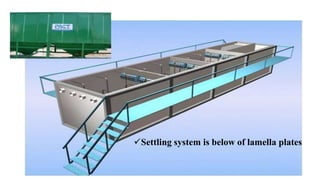

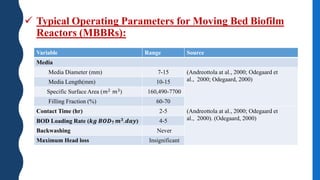

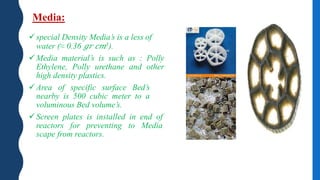

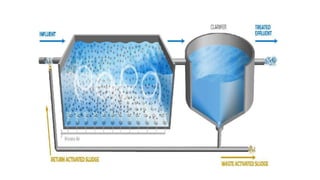

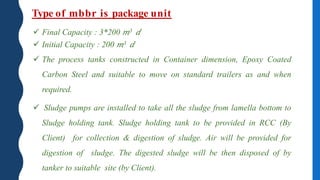

The document summarizes a moving bed biofilm reactor (MBBR) process for wastewater treatment. It was developed in the 1980s in Norway using plastic media to maximize treatment volume. Over 500 installations now exist worldwide. The MBBR uses floating plastic media in an aerated reactor to provide surface area for biofilm growth, combining suspended and attached growth. Wastewater flows through the aerated reactor and then to a settling tank for secondary treatment before chlorination and discharge.