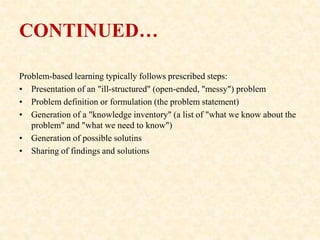

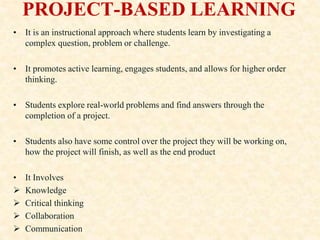

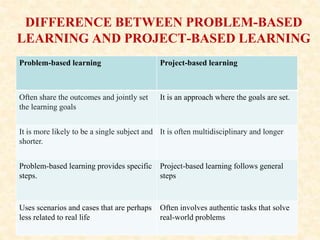

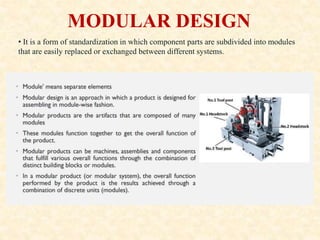

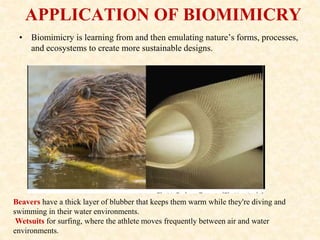

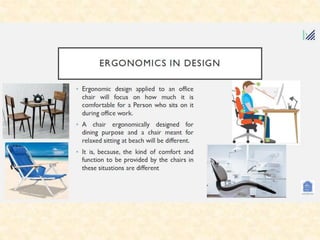

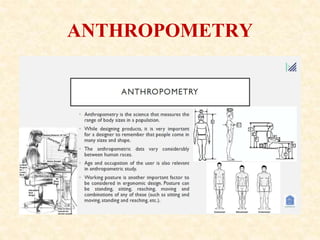

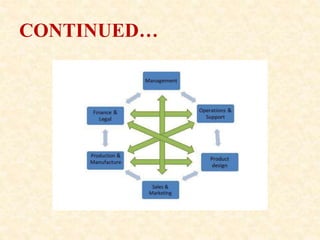

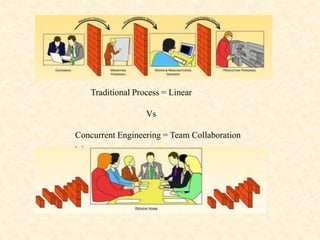

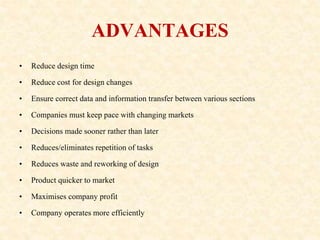

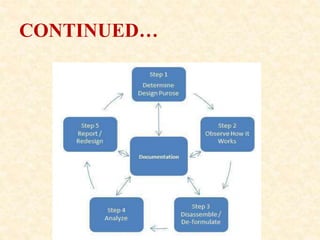

The document discusses various design engineering concepts including project-based learning, problem-based learning, modular design, life cycle design, biomimicry, ergonomics, aesthetics, concurrent engineering, and reverse engineering. It provides details on each concept, describing things like the process, advantages, and factors considered. Problem-based learning and project-based learning are compared. Modular design is explained along with its benefits. The stages of a product life cycle are outlined. Applications of biomimicry and factors for ergonomic design are also summarized.