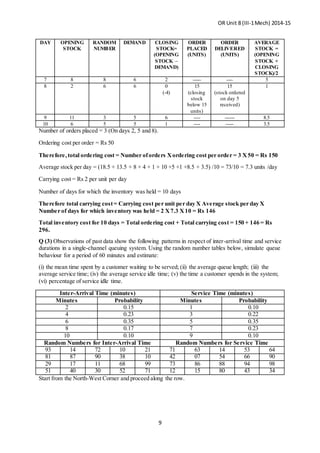

Simulation is used when it is difficult to construct an analytical model to solve a problem. It allows experimenting with changes to variables and parameters to understand how a real system performs without implementing changes in the real system. Some applications of simulation include aircraft design, pilot training, production planning, and modeling queuing systems. Simulation involves building a computer model of a system and running experiments to answer "what if" questions about how changes affect outcomes. It is useful for complex problems that cannot be solved analytically and allows low-cost experimentation with models of real systems.