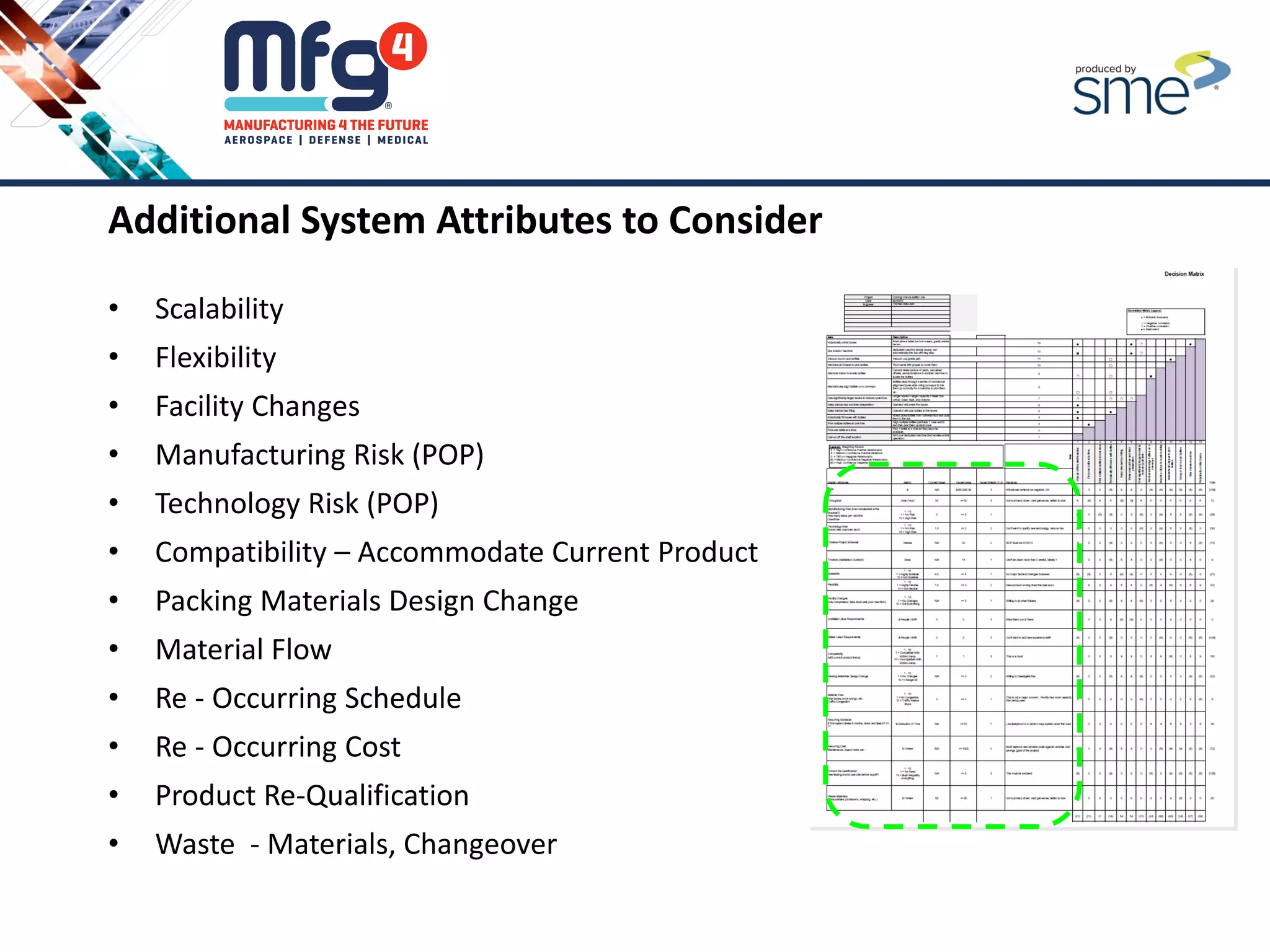

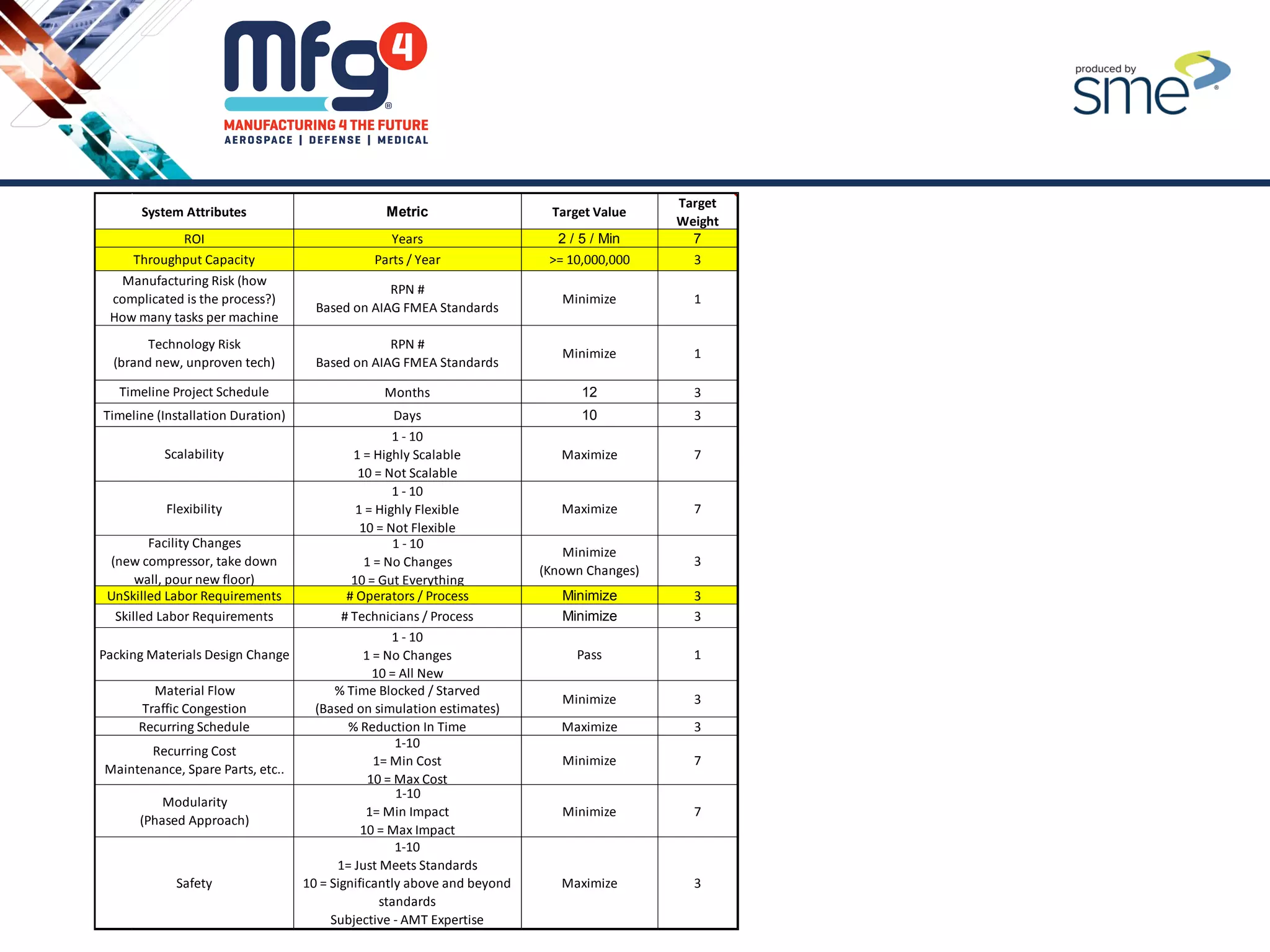

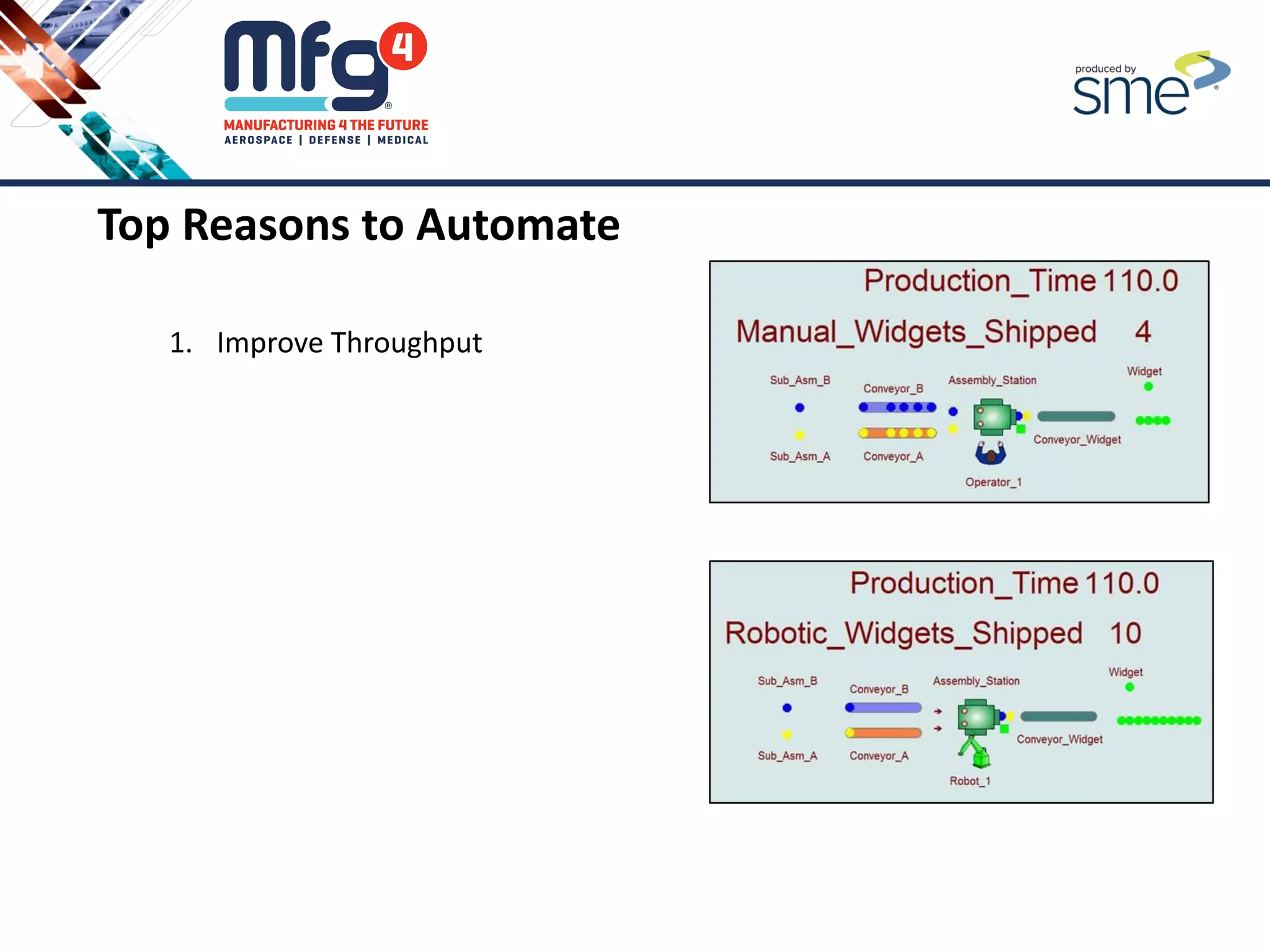

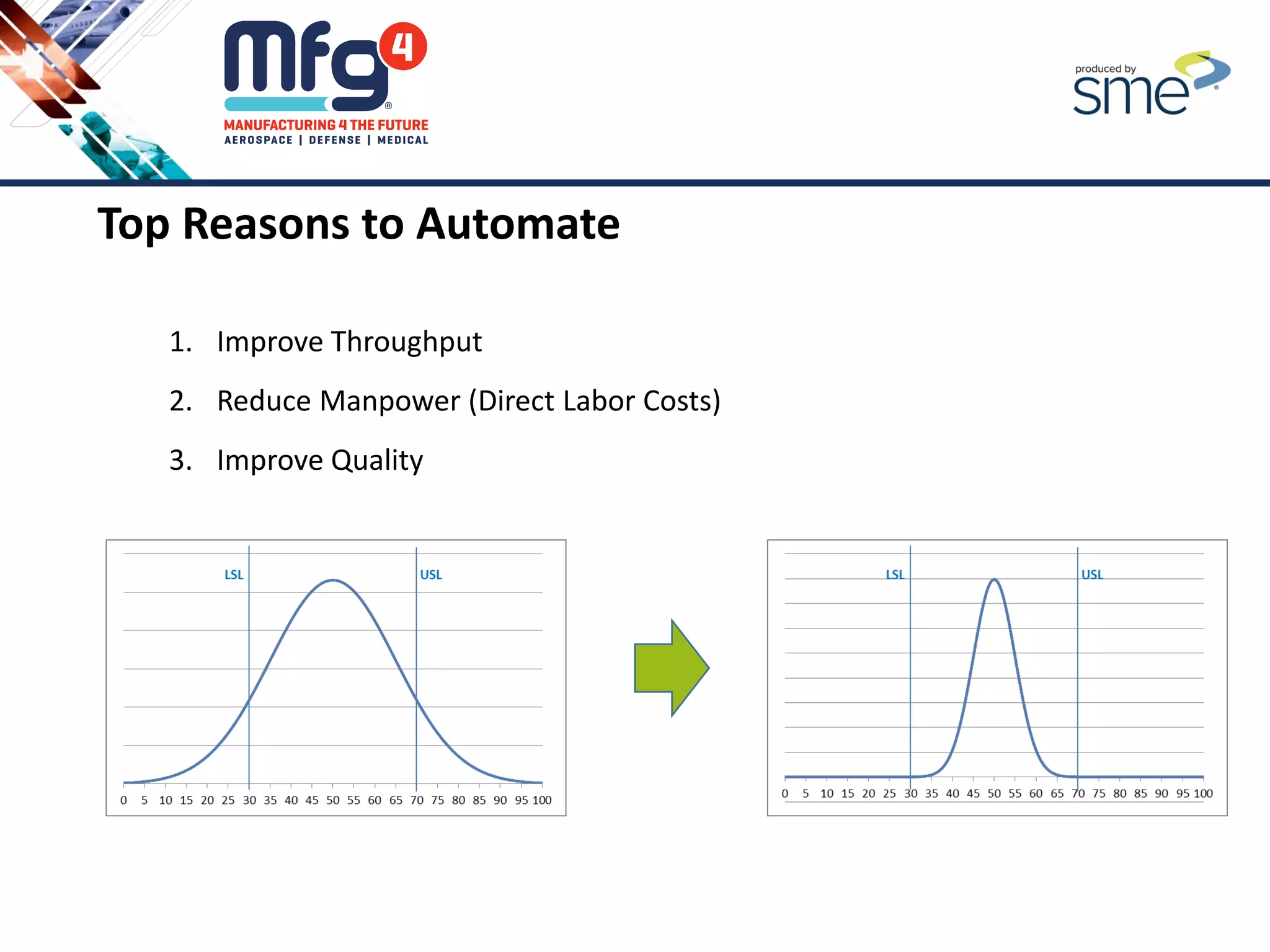

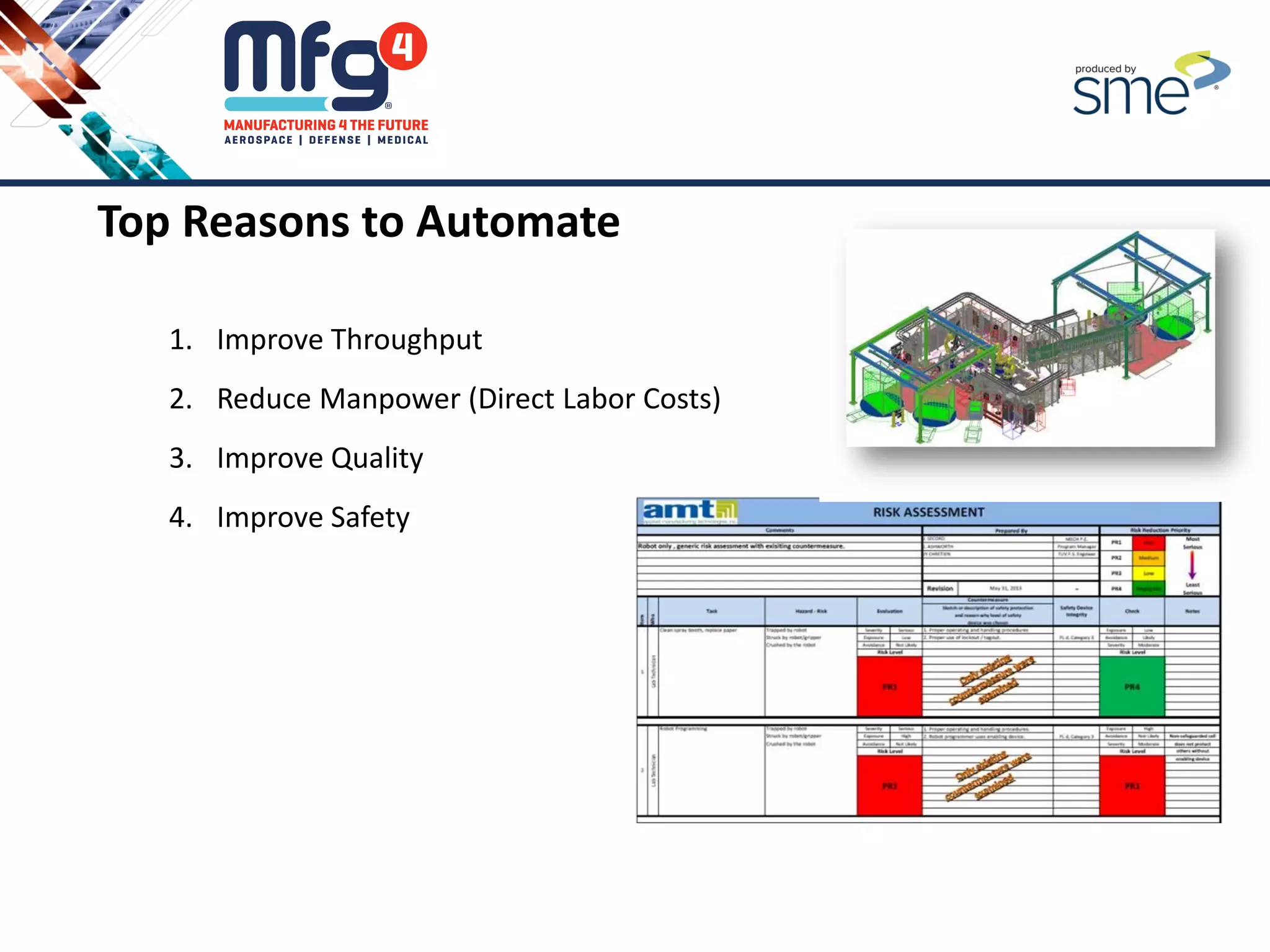

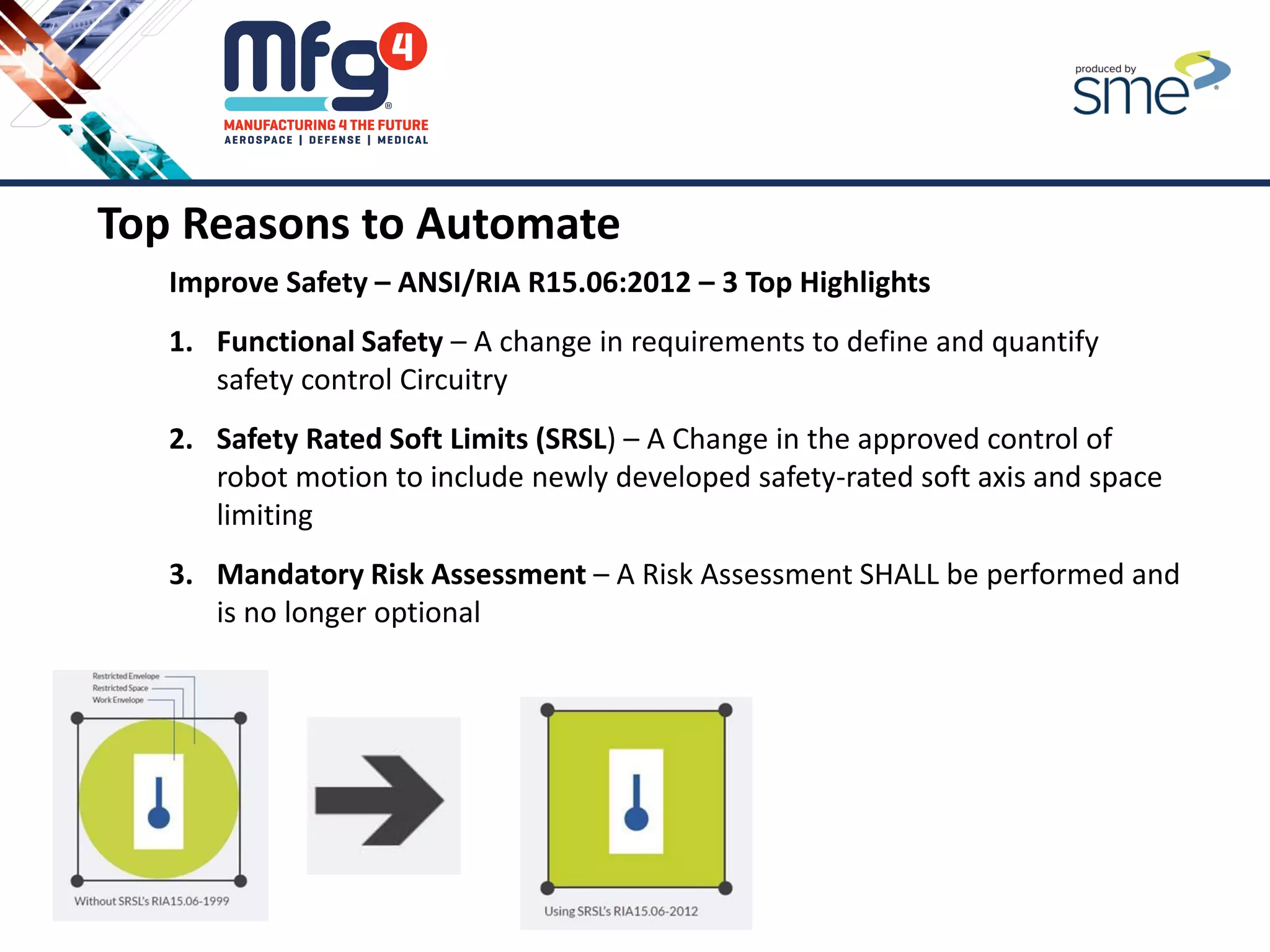

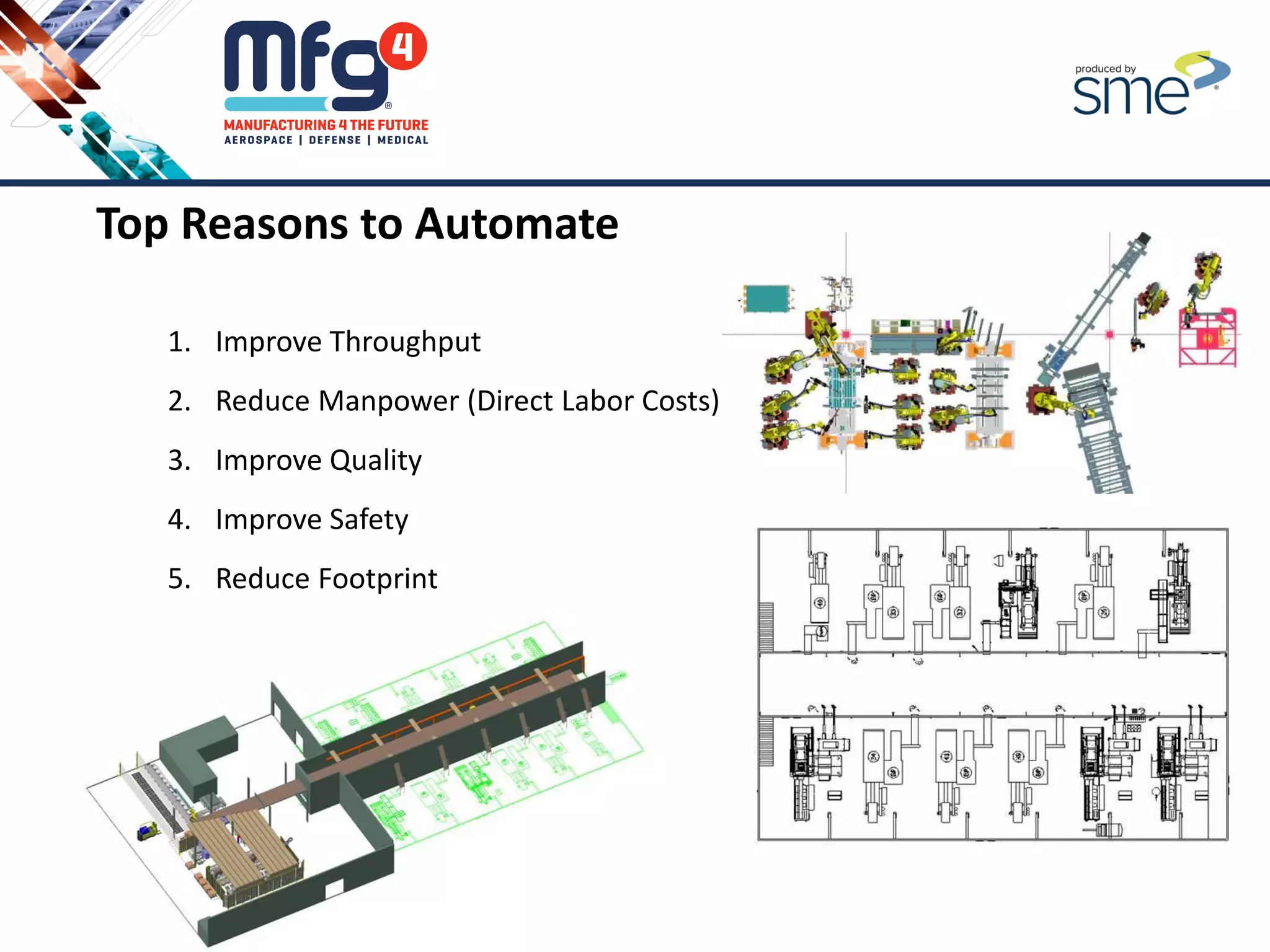

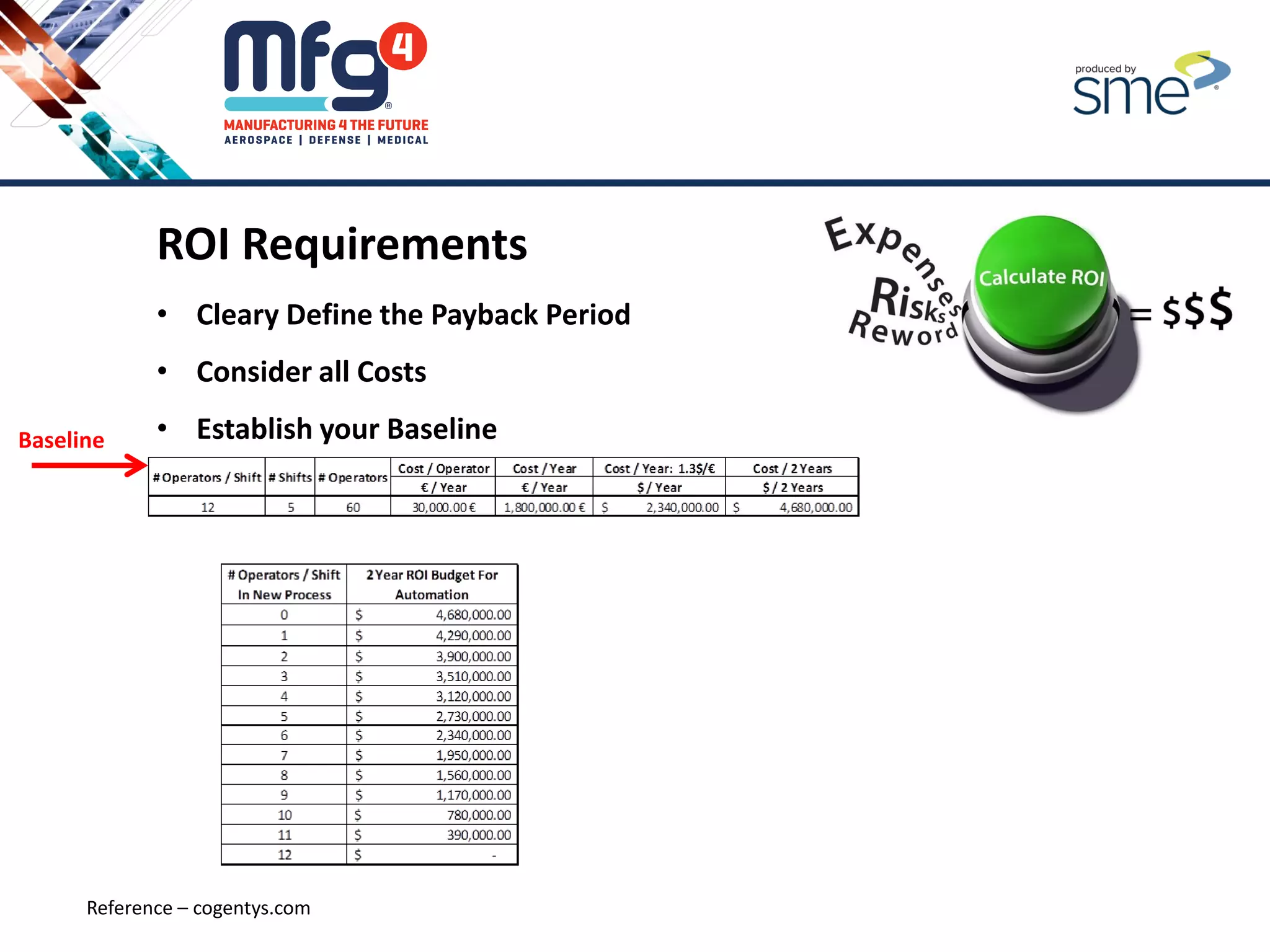

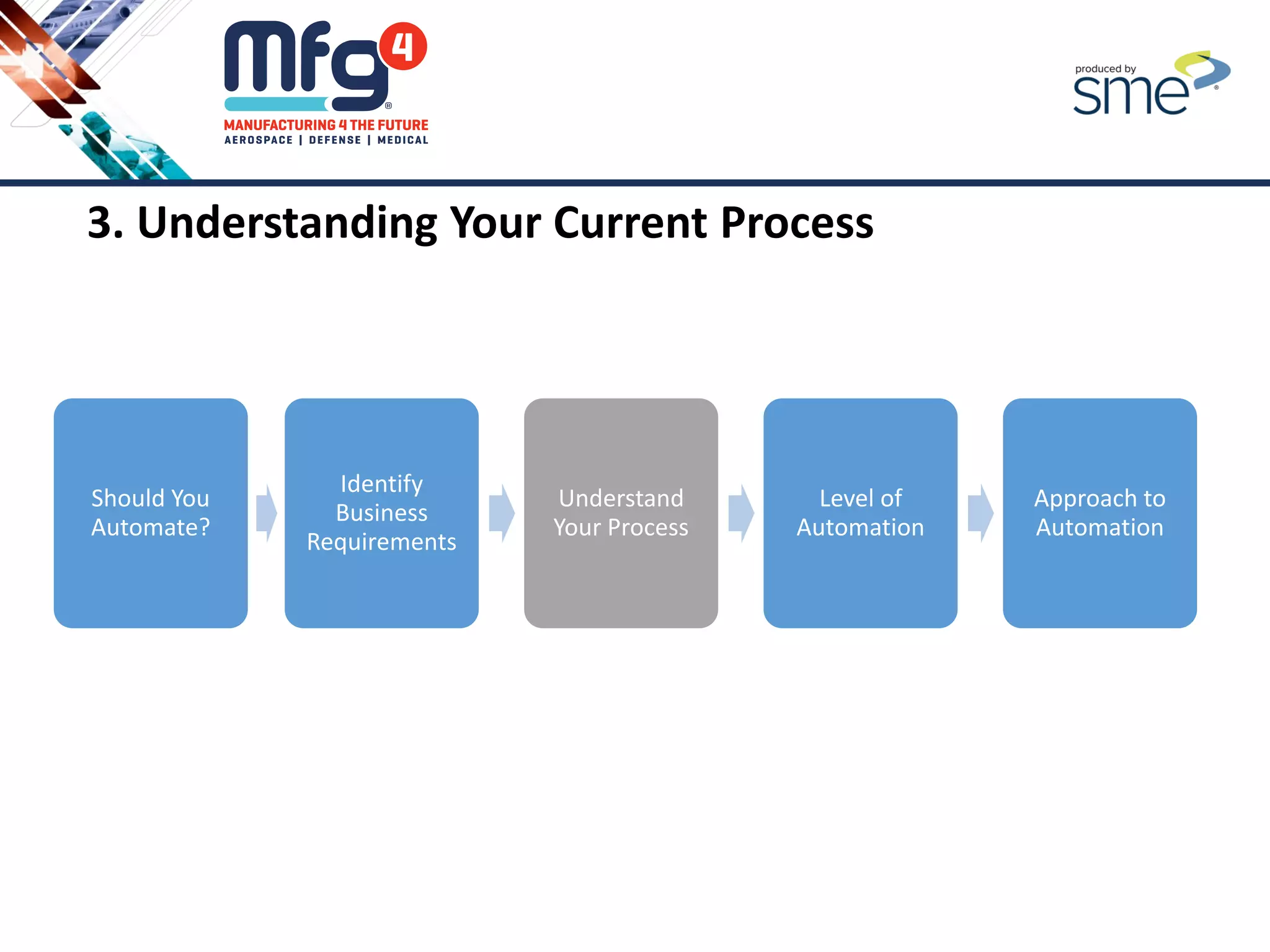

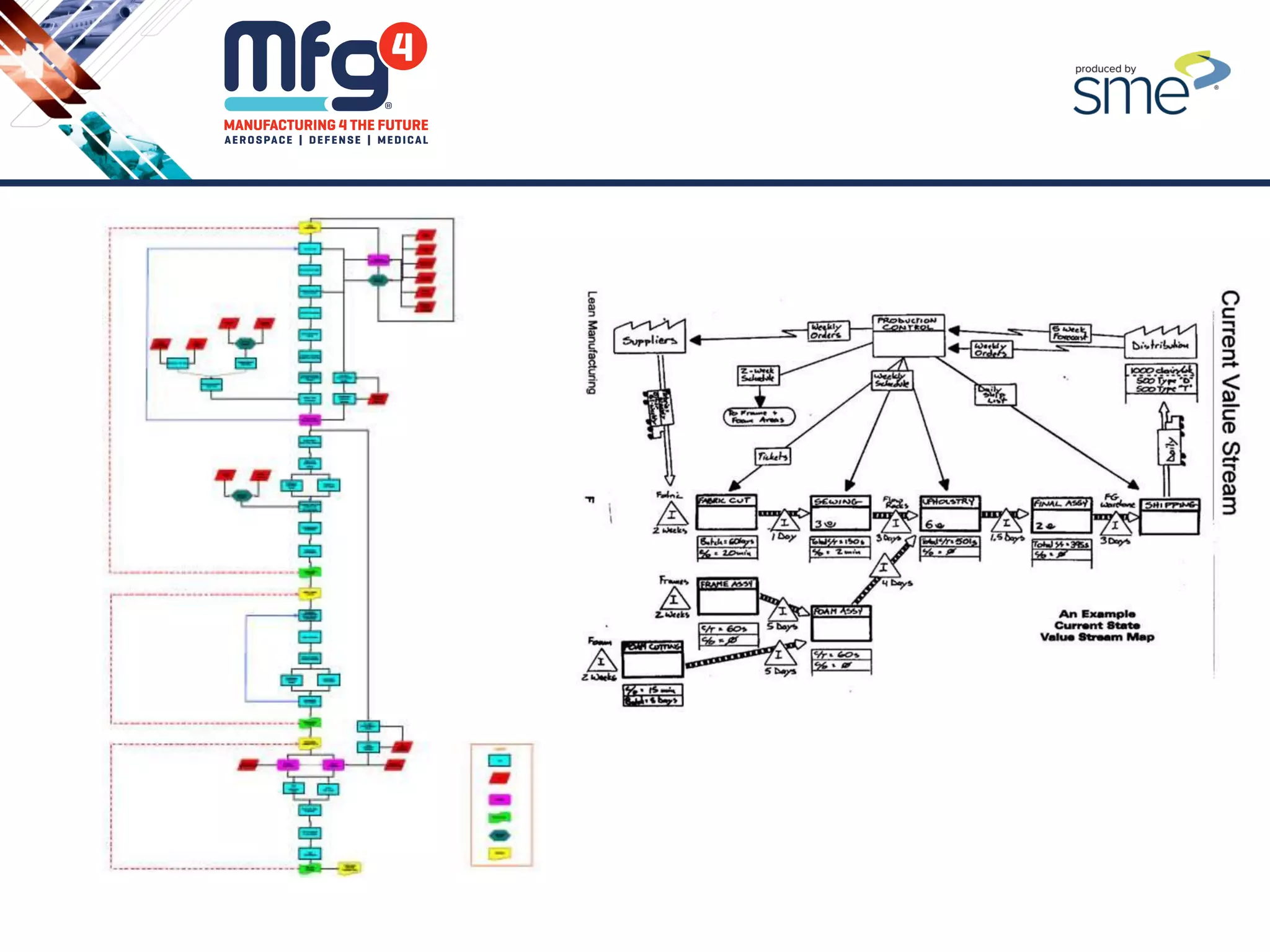

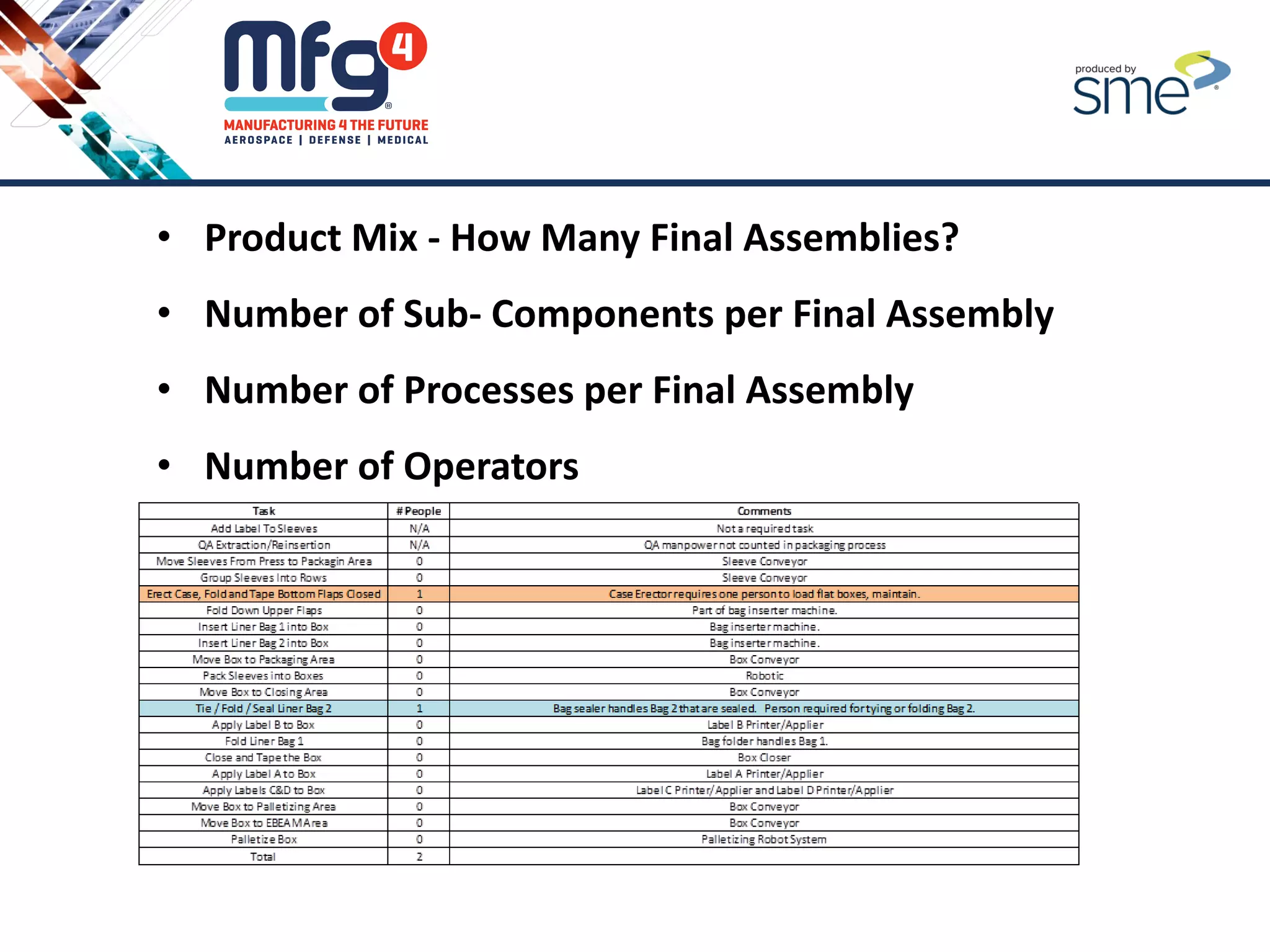

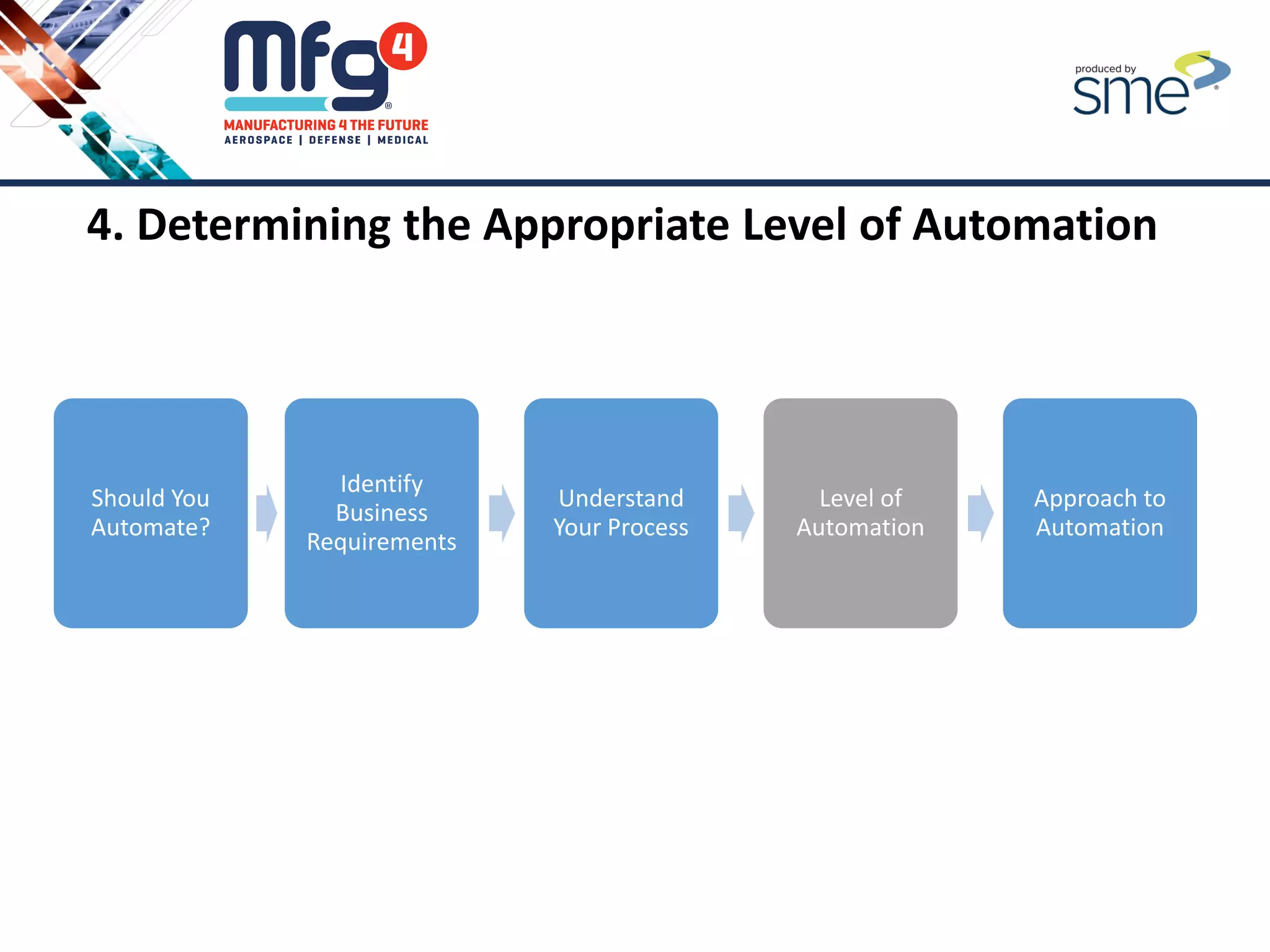

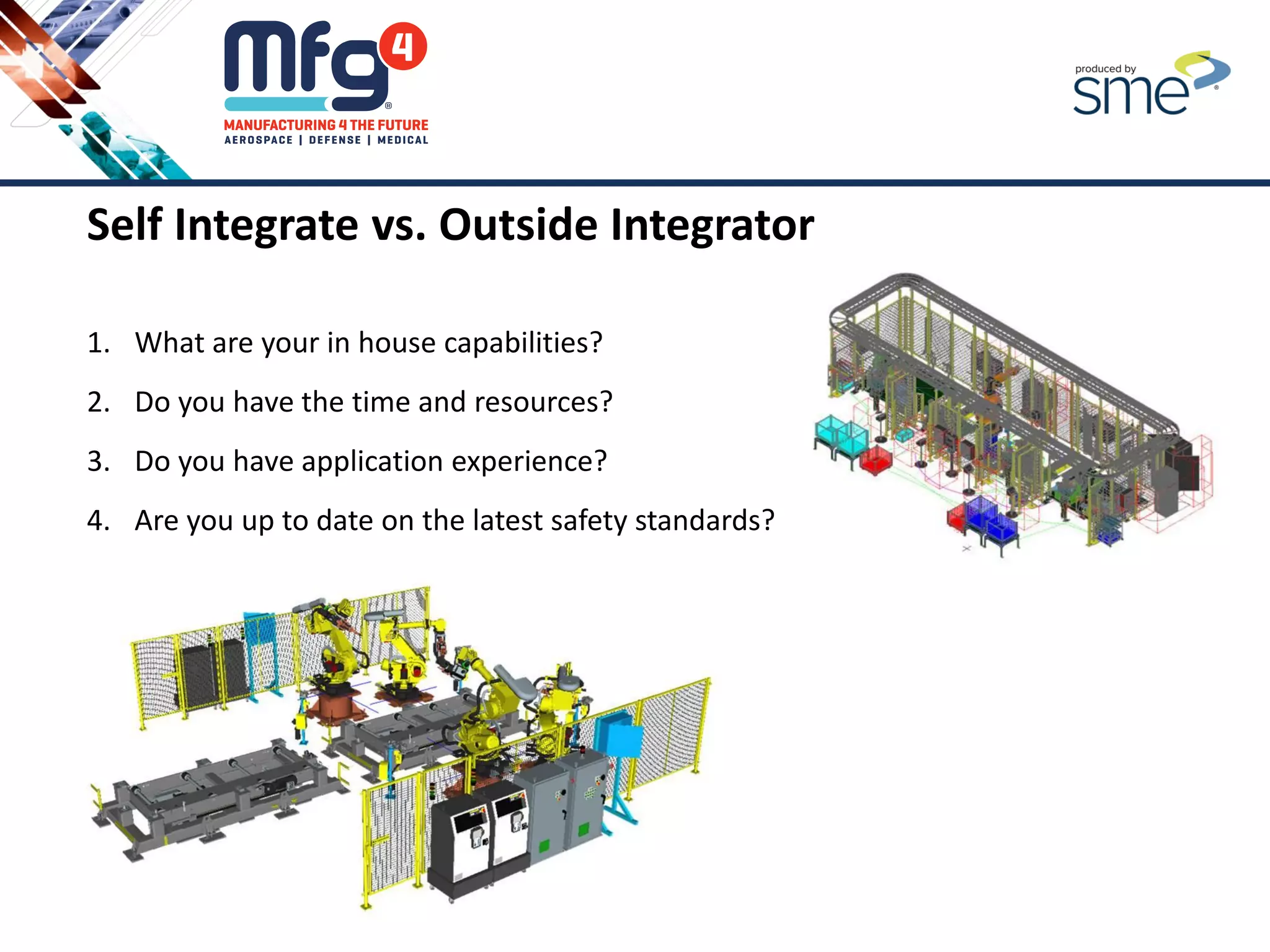

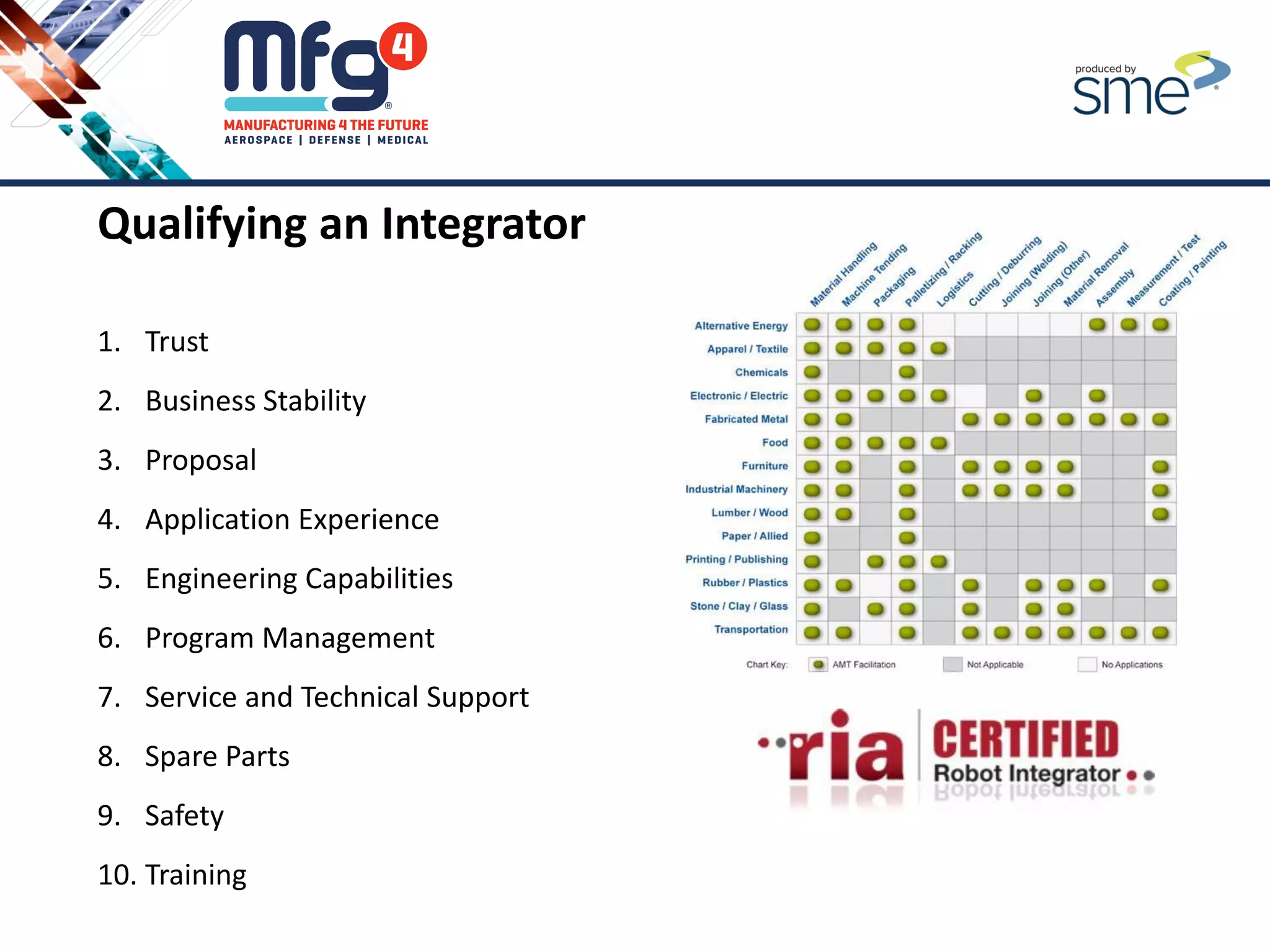

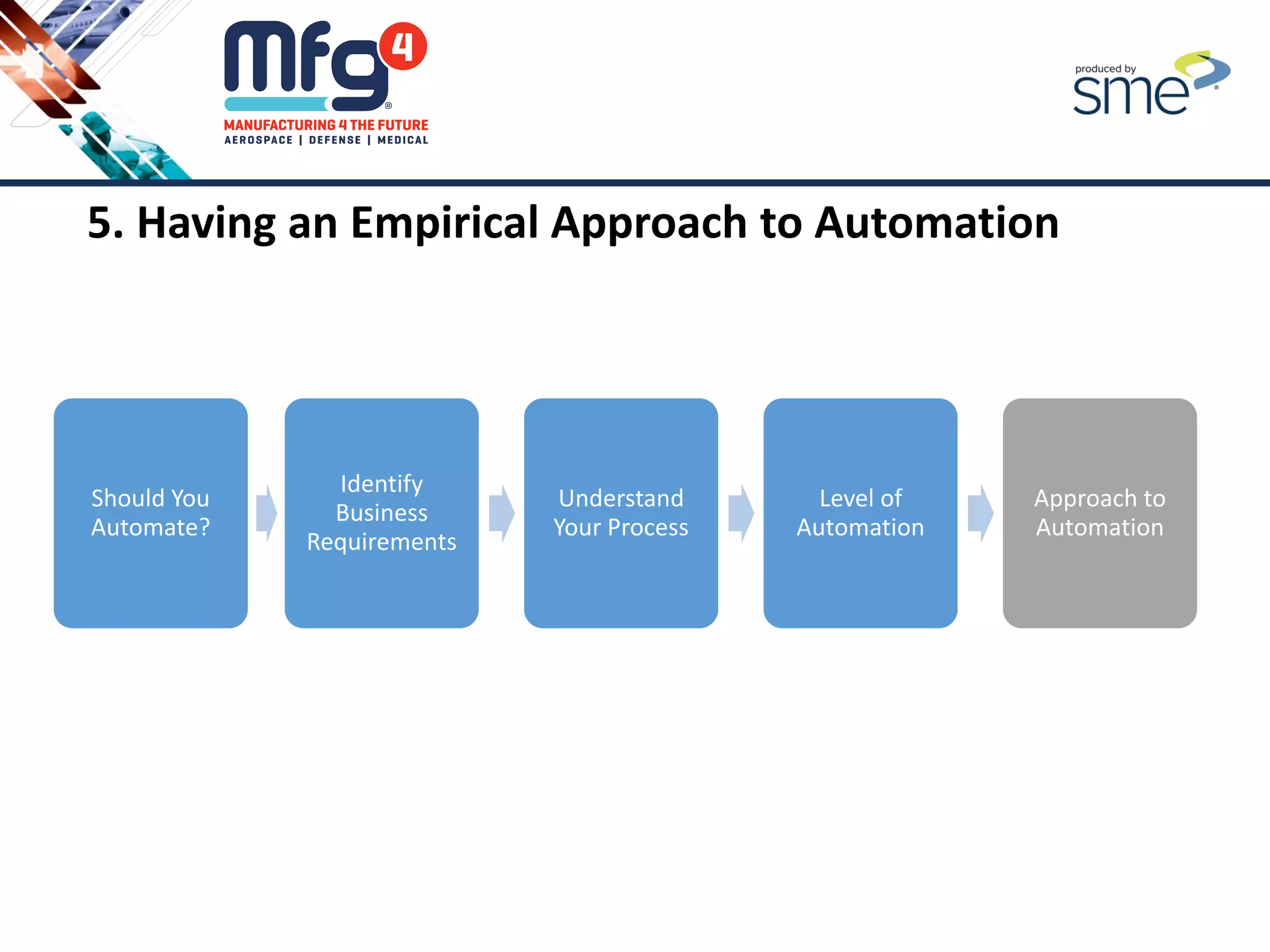

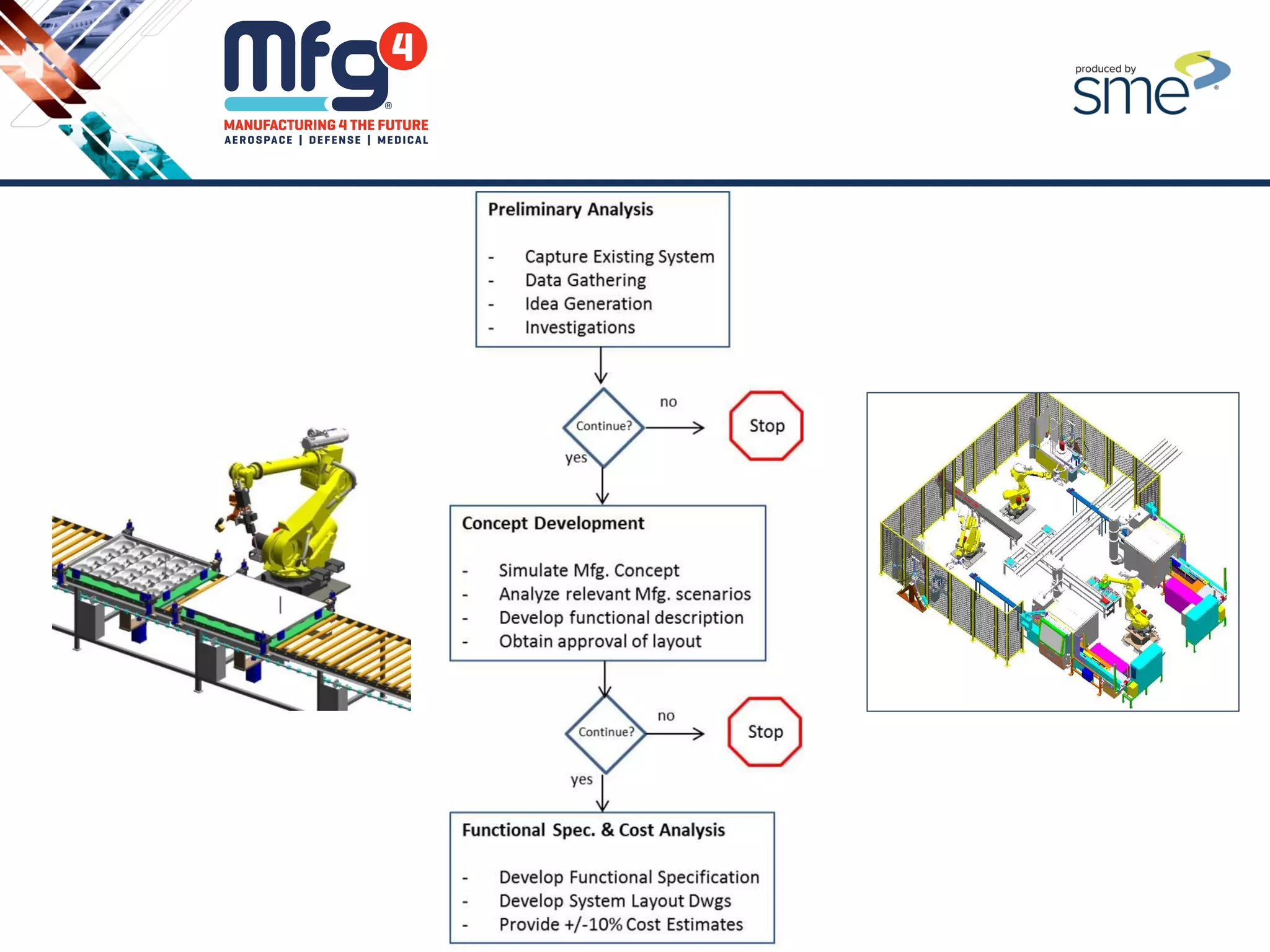

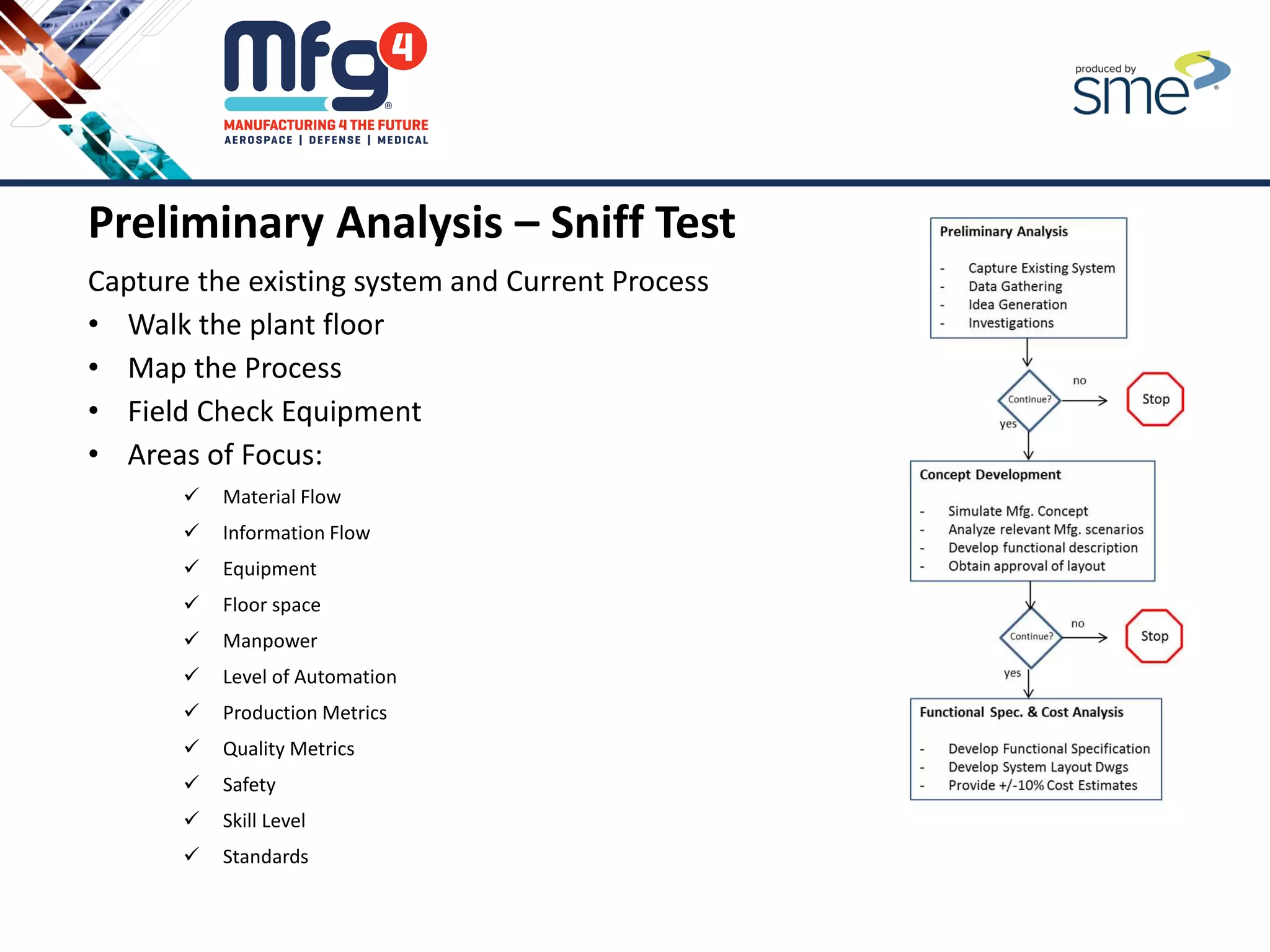

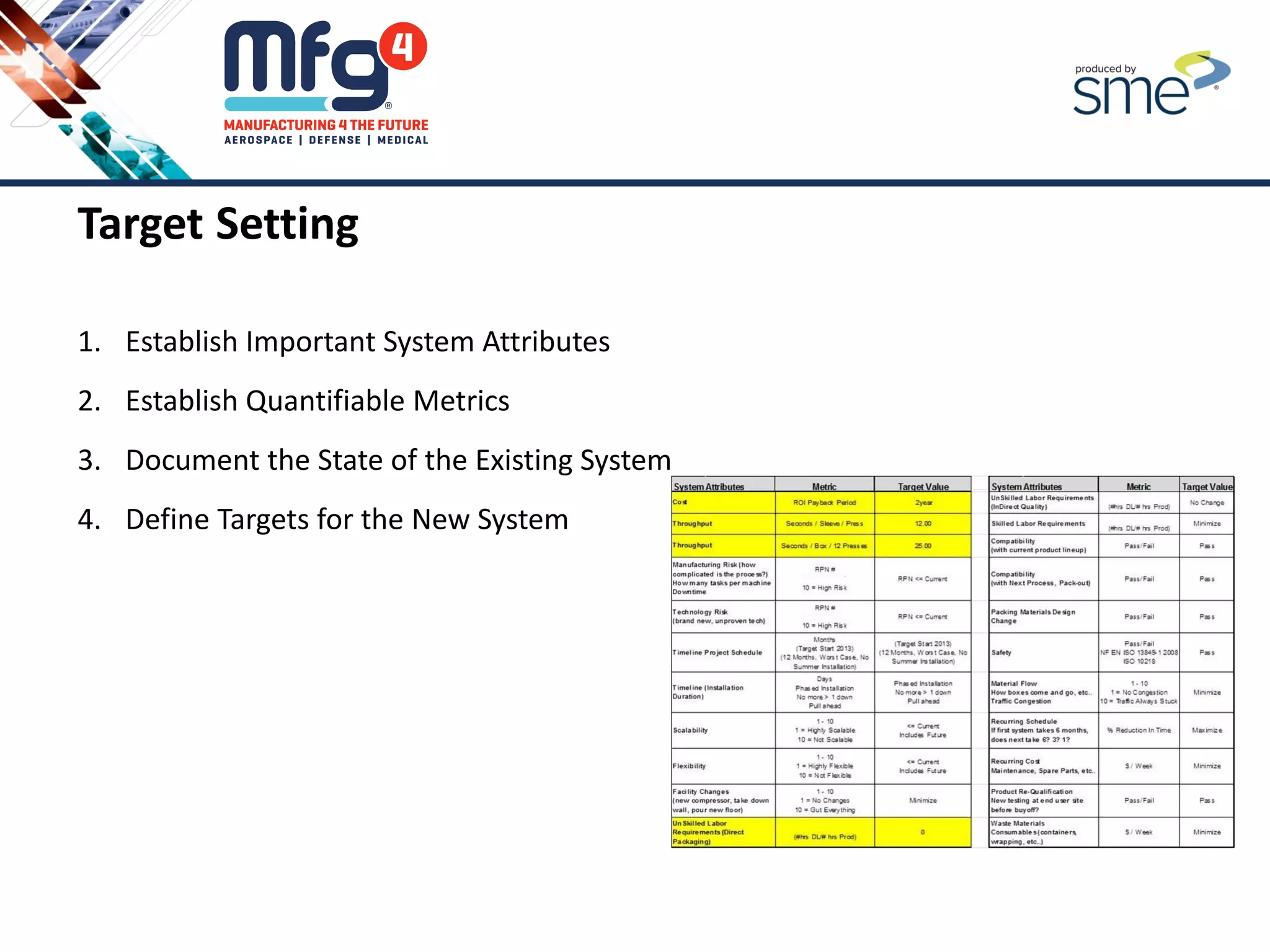

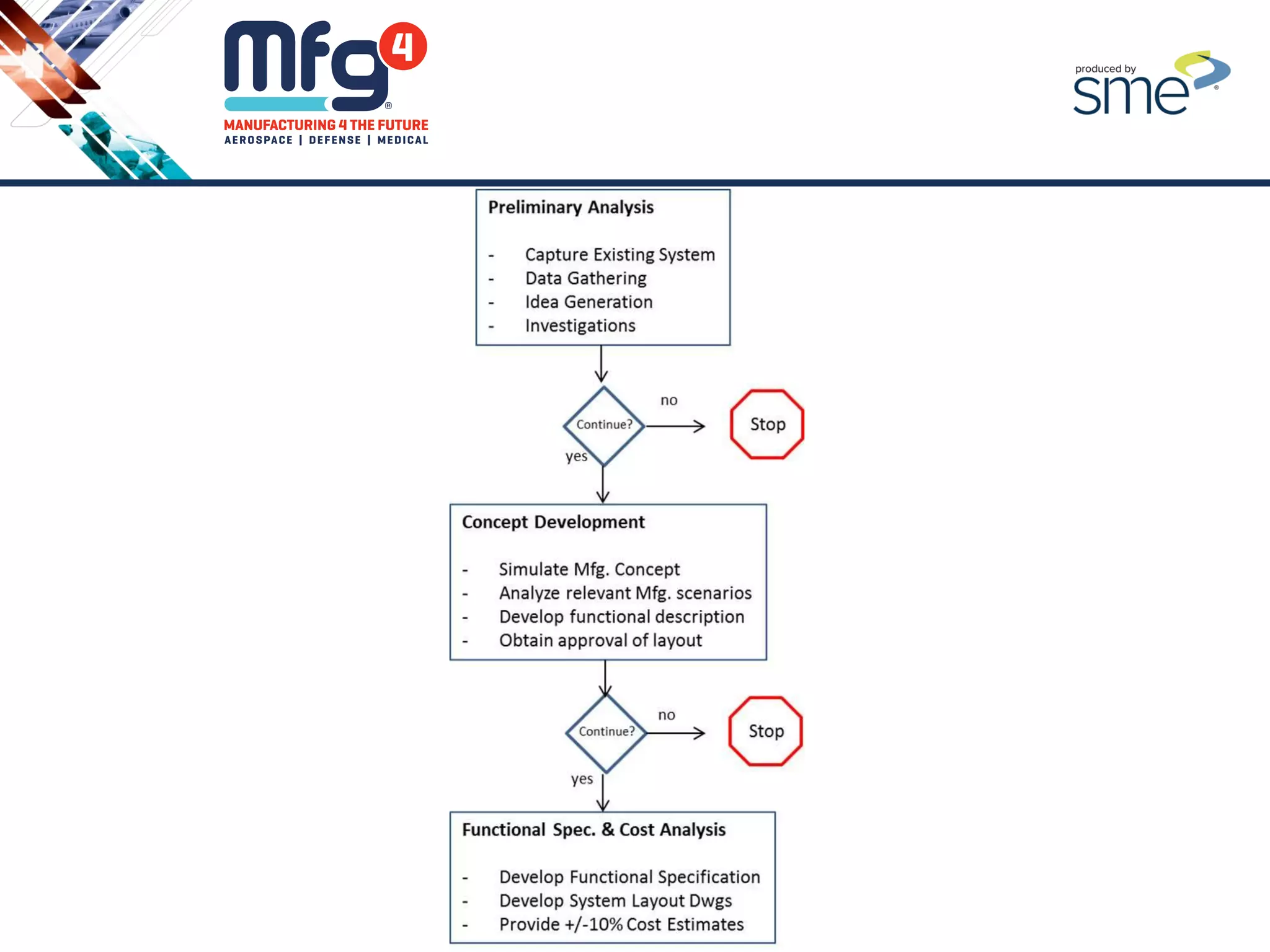

The document discusses factors to consider when determining if automation is appropriate for a company. It identifies the top five reasons to automate as improving throughput, reducing labor costs, improving quality, improving safety, and reducing footprint. It also outlines steps for understanding current processes, identifying business requirements, determining the appropriate level of automation, and taking an empirical approach to an automation project.