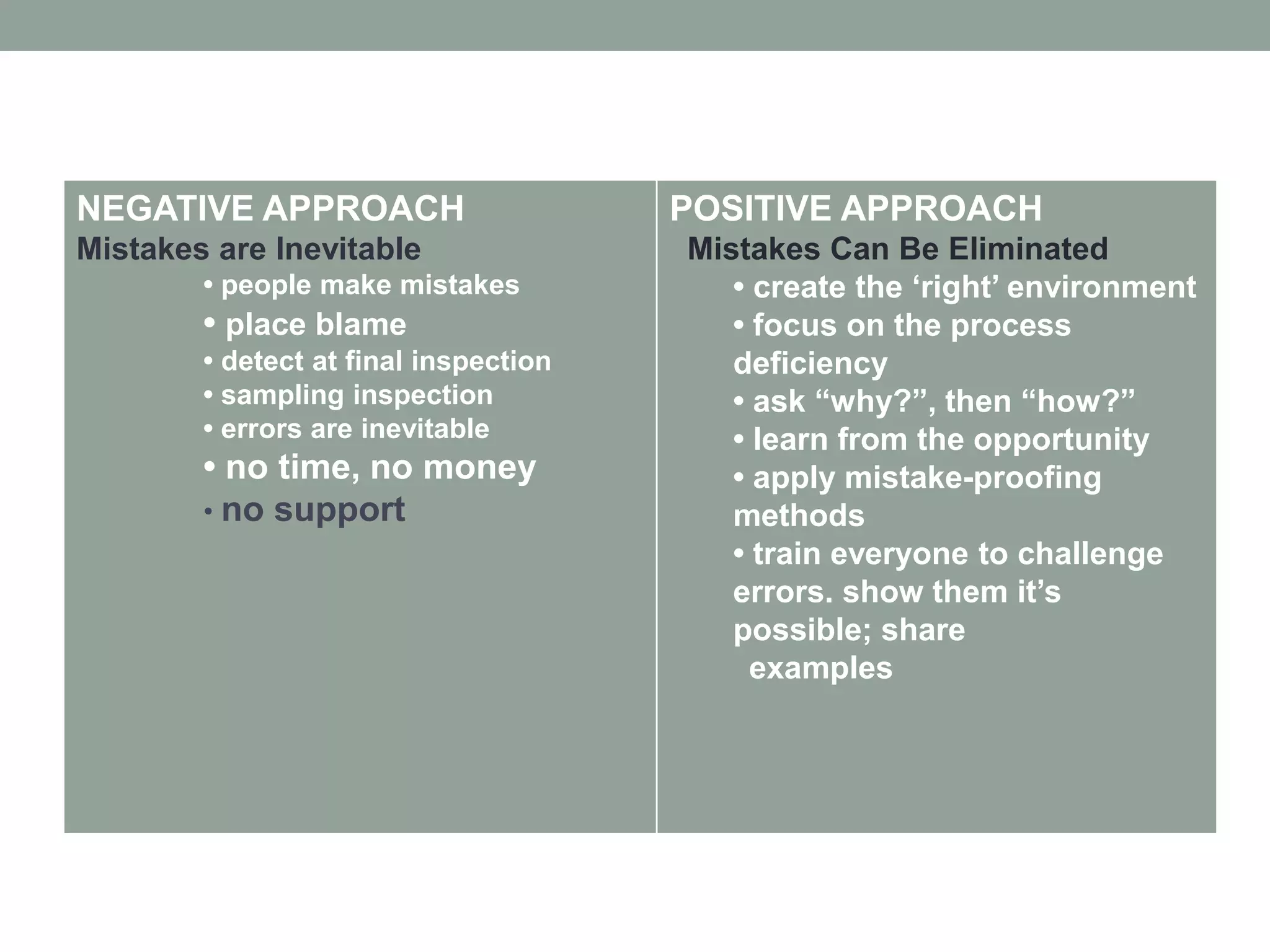

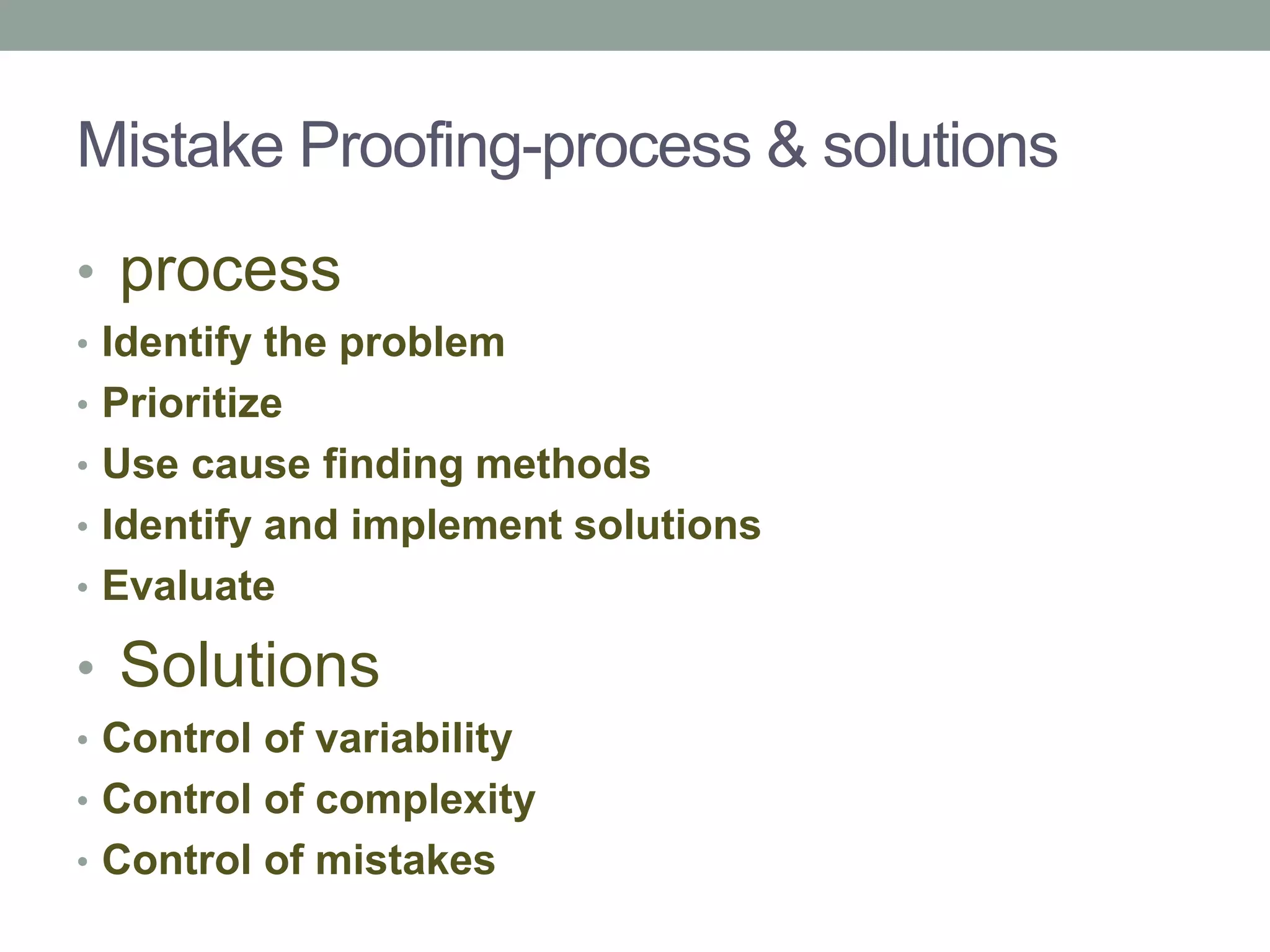

This document discusses mistake-proofing (poka-yoke) techniques for eliminating errors in manufacturing processes. It describes how poka-yoke aims to achieve zero defects through methods that prevent human errors early in product design. Common mistakes in manufacturing involve incorrect parts or tools, and poka-yoke provides physical devices that use contact or counting to shut down machines or warn of defects. Examples include limit switches, guides, fixtures, and sensors that help control processes and eliminate defects.