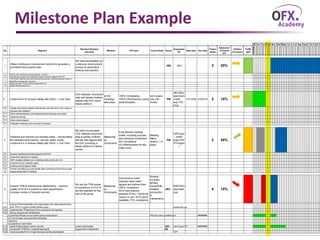

The document outlines the creation and use of a milestone plan for planning change initiatives and ensuring accountability within a project framework. It emphasizes identifying goals, assigning responsibilities, tracking progress, and incorporating continuous improvement practices. The planning process includes the use of prioritization tools, task delegation, and regular reviews to maintain alignment with the organization's site vision.