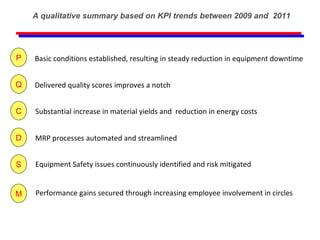

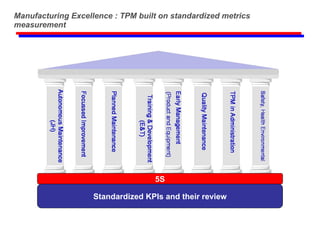

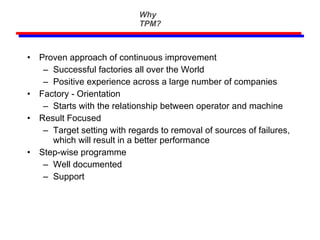

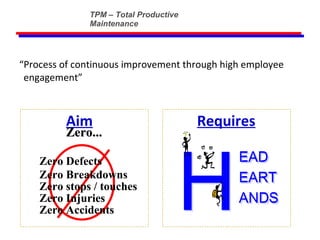

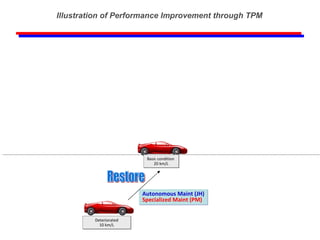

The document summarizes the implementation of a Total Productive Maintenance (TPM) program at a manufacturing facility between 2009 and 2011. Key performance indicators showed steady reductions in equipment downtime, improved quality scores, increased material yields, and reduced energy costs. The TPM program was built on standardized metrics, measurement, and review processes. It utilized a proven approach of continuous improvement through high employee engagement and a step-wise implementation plan. The goals of the program were to continuously improve performance by removing sources of failures and establishing autonomous and specialized maintenance practices.