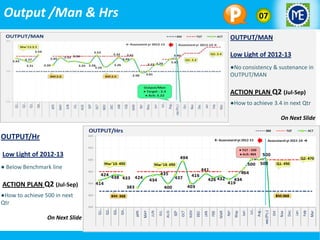

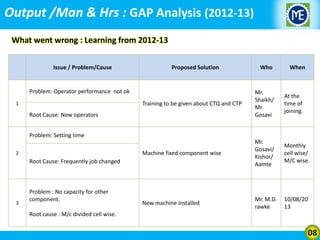

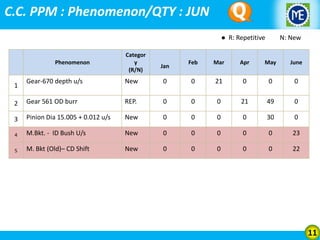

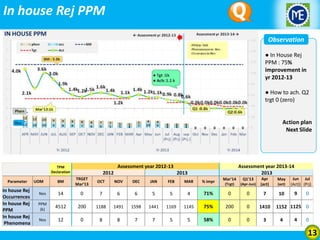

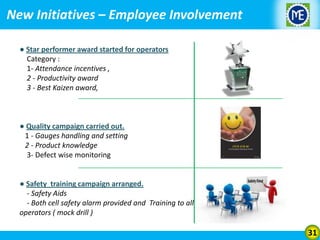

Manish Engineering Works conducted a TPM review meeting on July 17, 2013. The summary discusses:

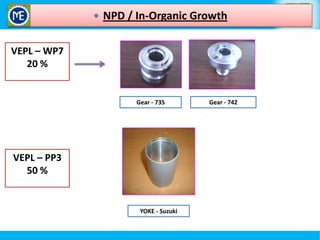

1) Organic and inorganic growth strategies including new product development plans.

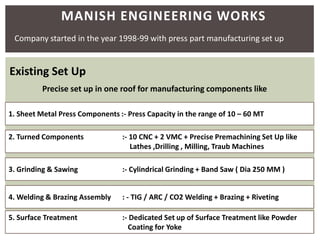

2) An overview of Manish Engineering's manufacturing capabilities across various processes like sheet metal components, CNC machining, grinding, welding and surface treatment.

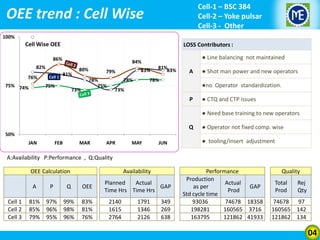

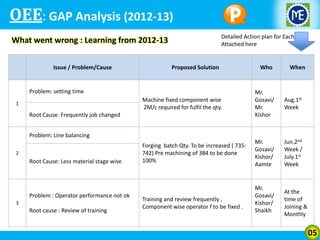

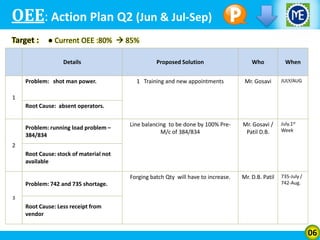

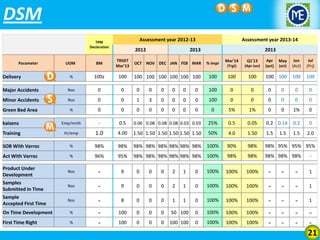

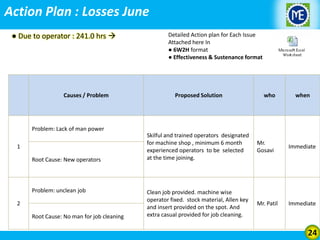

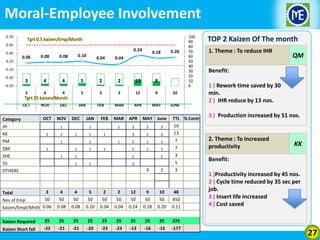

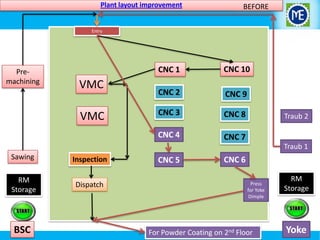

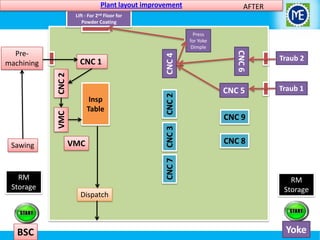

3) TPM implementation progress covering activities in areas like 5S, quality, delivery performance, defect reduction and policy deployment. Targets and plans are discussed for further improving overall equipment effectiveness.

![TPM PROGRESS EXECUTION

Parameter

Activities

Activities

A] TPM declaration with TPM policy.

29.11.11

B] Education to all employees.

1S- 2S Training Completed.

A] No unwanted material.

Done.

B] Prefix location, Prefix quantity.

Done.

A] Handling as per agreed norms in

container/Trolley

Plastic Bins

B] Elimination of quantity shortages

container should have visual countability.

Plastic Bins with partition & Part

wise Qty.

A] Study of fitment, Aesthetic & Functional

Parameters & implementation of perfect inspection

system for all parts.

All components fitment and

functional parameters known to all

section heads and resp.operators.

B] Cause side Kaizens & Poka-Yokes implementation

& sustenance.

Training given to all & examples

shown.

In-house

Defects

A] Defect stratification by ABC way.

-

B] Implementation of countermeasures/Kaizens

following PM analysis way.

Activity in continuations

Delivery

Performance

A] No line stoppages at customer end.

No line stoppages

B] Daily/Weekly/Monthly delivery adherence.

Daily

TPM Policy

1S~2S

Material

Handling

Customer

Complaints](https://image.slidesharecdn.com/manishprogressreview-aug20131-131019072746-phpapp02/85/Manish-Engineering-Works-7-320.jpg)