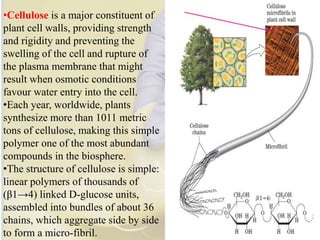

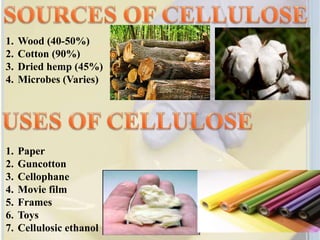

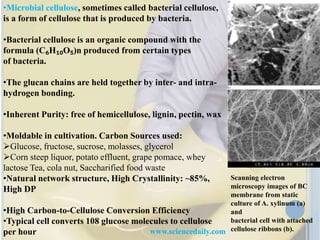

This document discusses bacterial cellulose, including its production, structure, and applications. It notes that bacterial cellulose is produced by certain bacteria through a multi-step biosynthesis process. It is composed of glucose monomers linked together into long chains that aggregate to form a strong yet flexible fiber. The document outlines factors that affect bacterial cellulose production, such as carbon sources, pH, oxygen levels, and production methods like static cultures or bioreactors. It also compares bacterial cellulose to plant cellulose and discusses some advantages and disadvantages for commercial use.