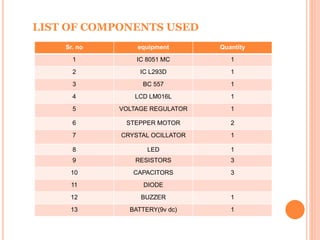

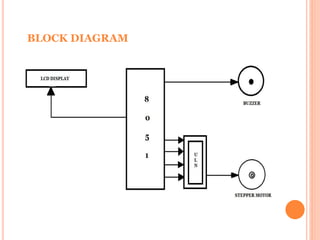

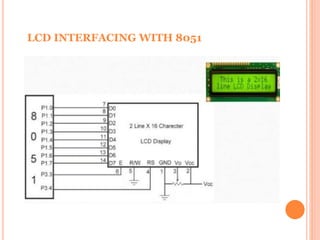

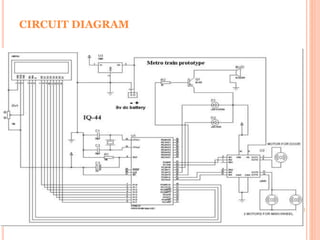

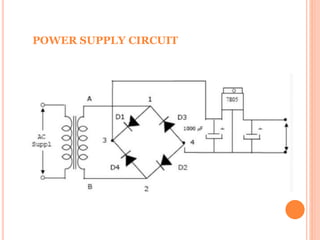

This project aims to create a prototype for a driverless metro train. An 8051 microcontroller is used to control the motion of a stepper motor that moves the train. An LCD display shows messages and the train's position at stations. Sensors provide input to the microcontroller to stop the train at stations for 3 seconds and travel between stations in 6 seconds. LEDs indicate the train's direction and a buzzer sounds when approaching a station. The basic circuit includes a power supply, microcontroller, display unit, and stepper motor. This project could help reduce costs and increase safety compared to traditional trains.