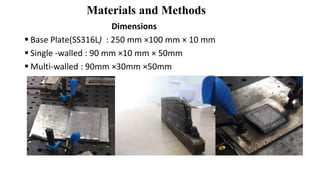

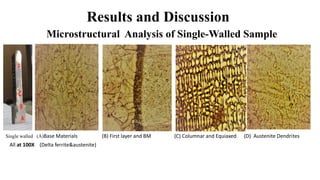

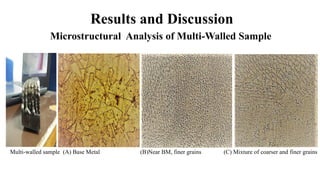

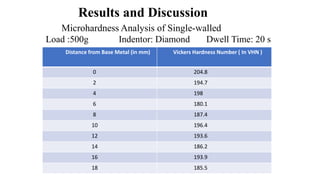

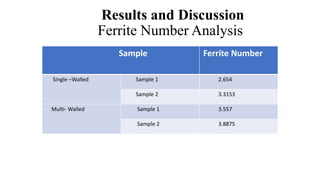

This document presents an analysis of single and multi-walled 316L stainless steel samples manufactured using Cold Metal Transfer-based Wire Arc Additive Manufacturing (WAAM). It discusses the advantages of WAAM, including reduced material wastage, high deposition rates, and improved microstructure stability, while also providing experimental conditions and results related to hardness, microstructure, and ferrite content. The findings indicate that multi-walled samples exhibited higher hardness and ferrite content compared to single-walled samples due to variations in heat input during the welding process.