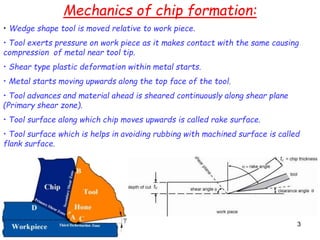

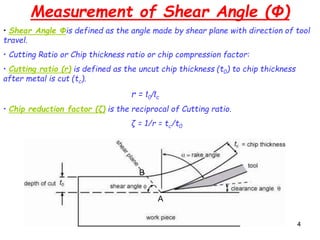

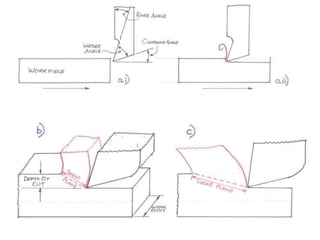

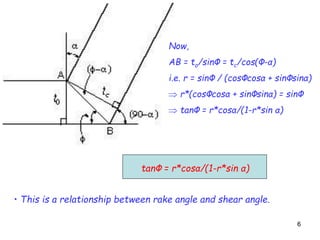

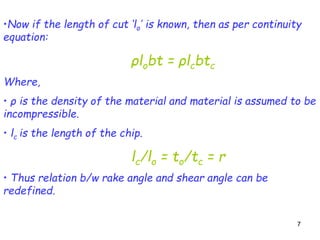

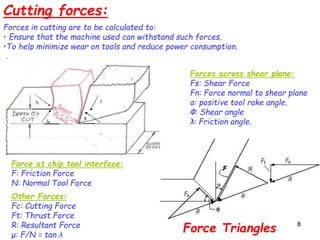

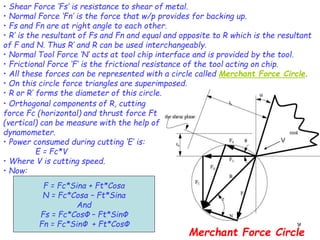

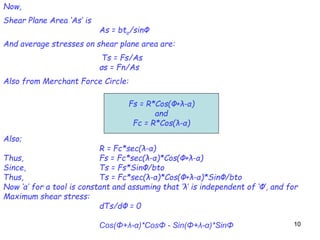

This document discusses the analysis of cutting forces in 2D orthogonal metal cutting using Merchant's circle theory. It introduces the mechanics of chip formation where a wedge-shaped tool shears metal along the primary shear plane at an angle (φ). Merchant's circle relates the shear angle (φ), rake angle (α), and friction angle (λ) and can be used to calculate cutting and thrust forces. The maximum shear stress theory states that the shear angle is selected to minimize the energy of cutting and is calculated based on α, λ, and an assumption that the material behaves plastically. Key cutting force relationships and assumptions of Merchant's model are also outlined.