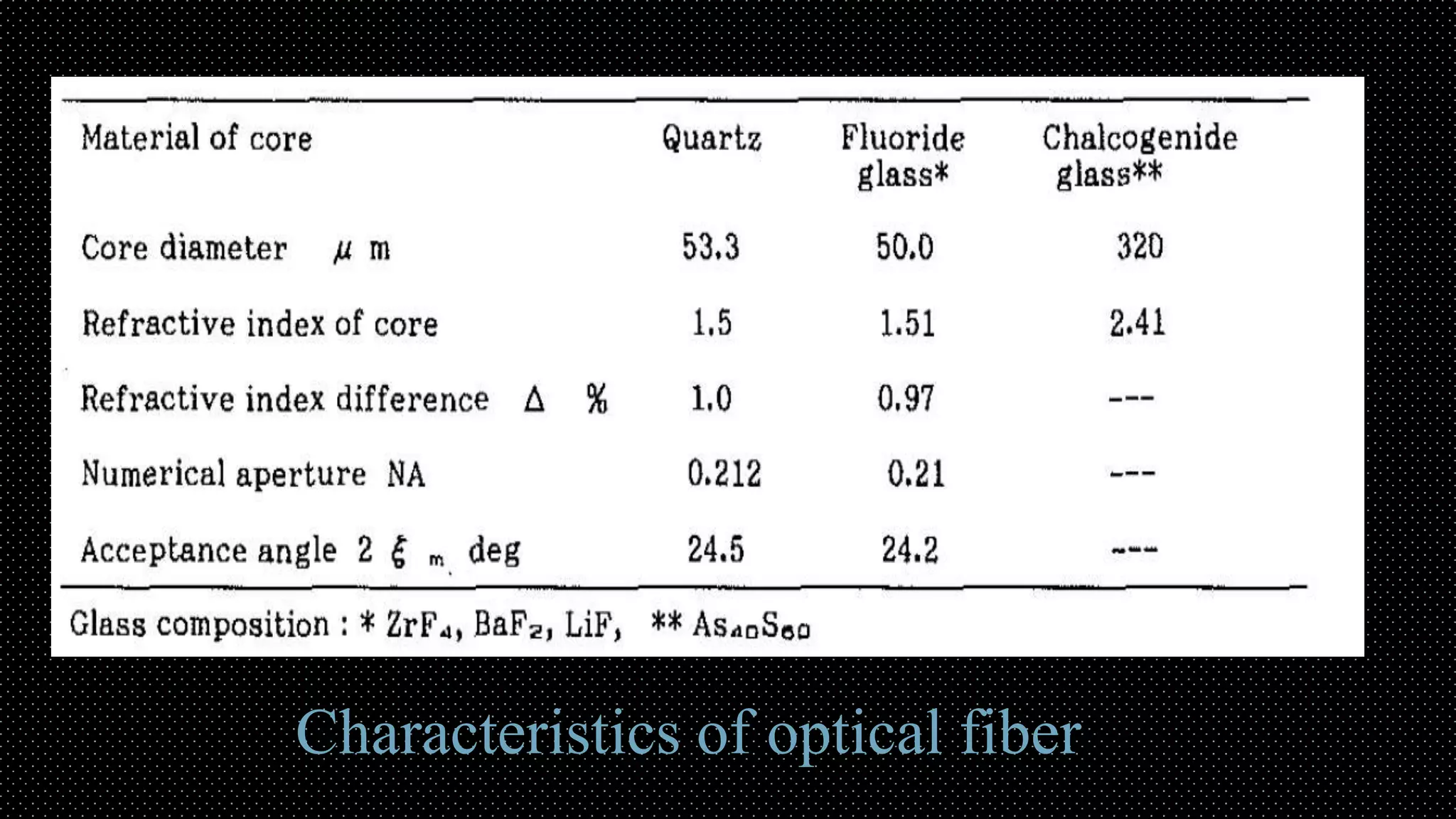

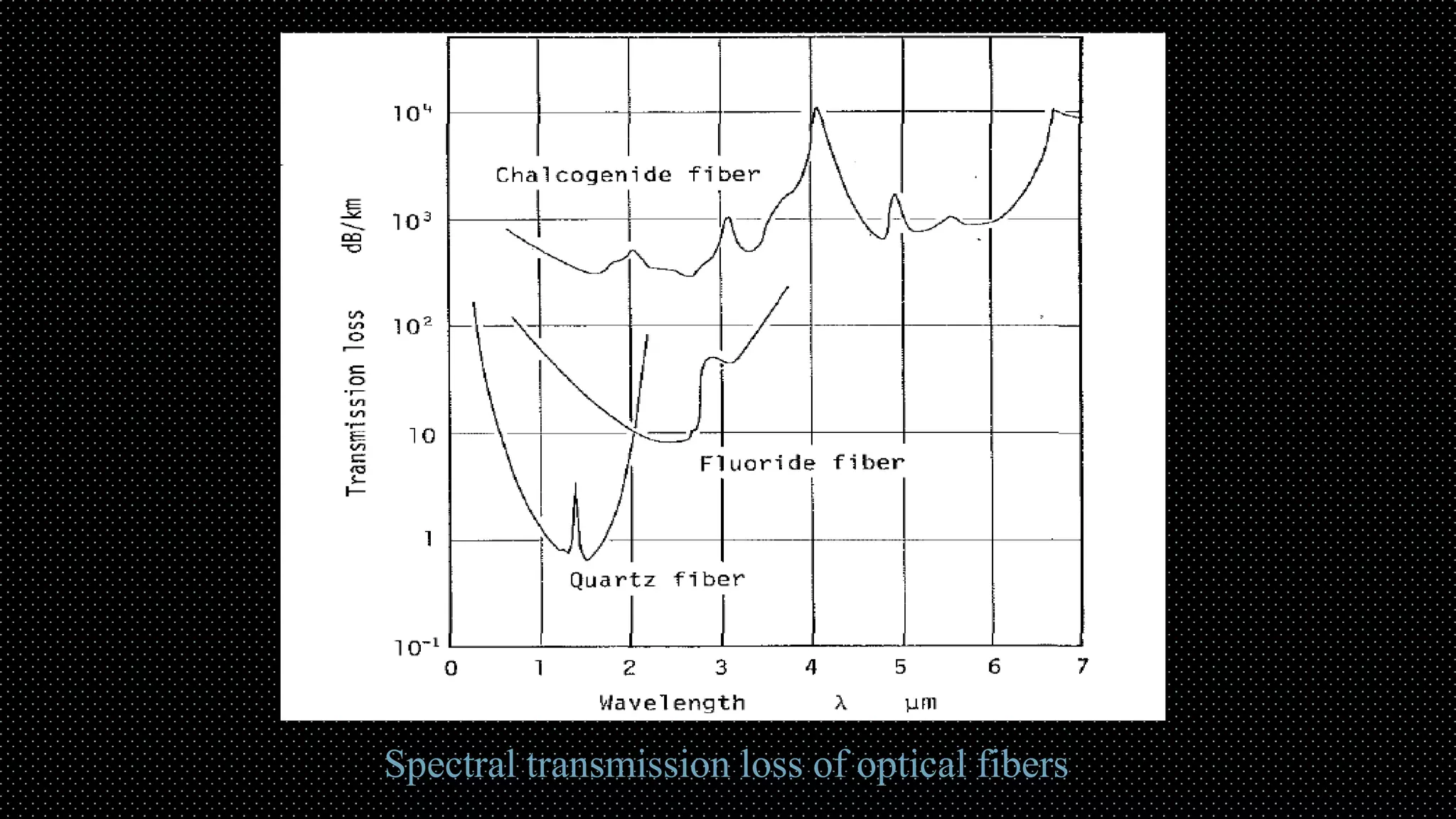

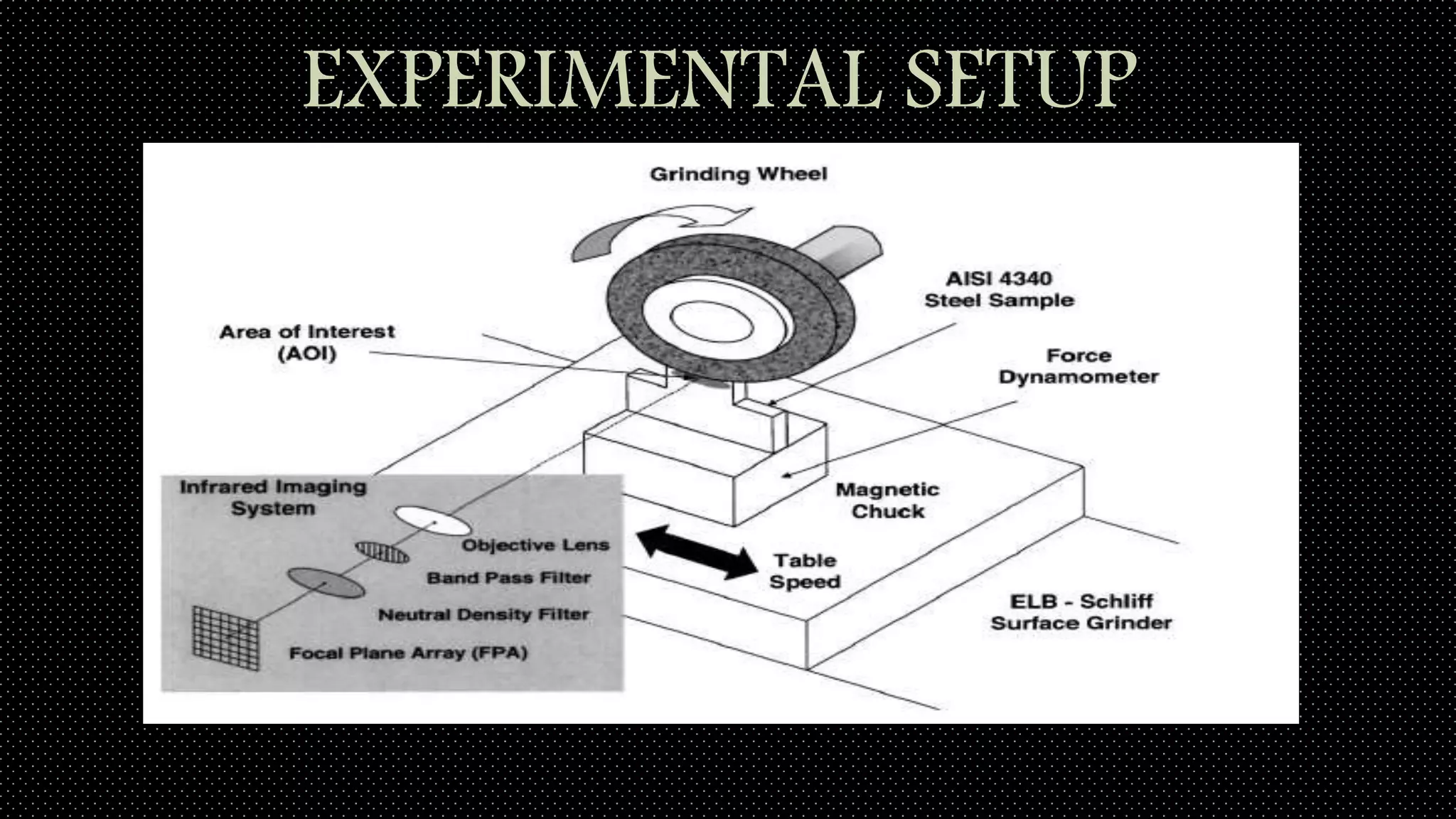

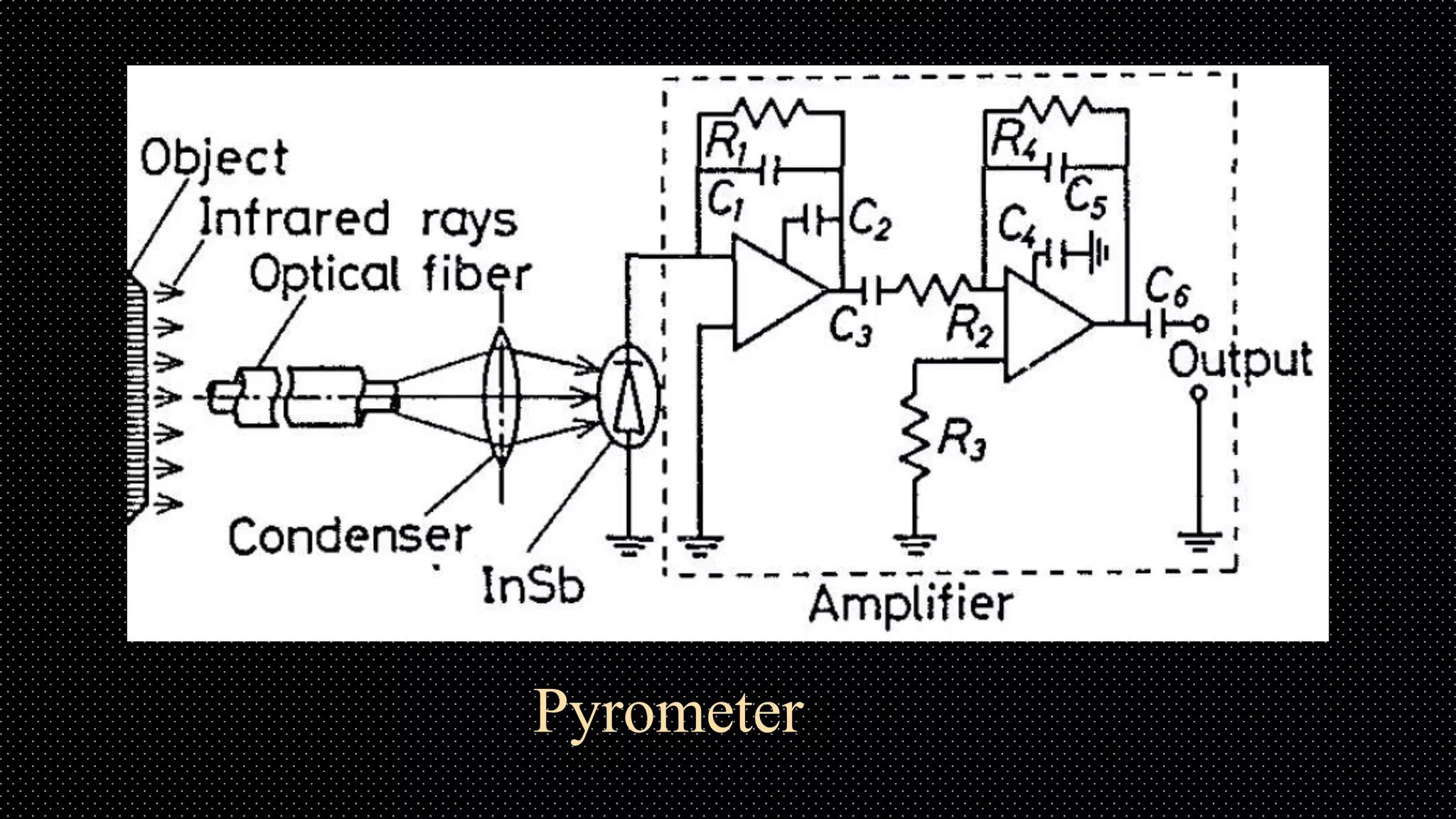

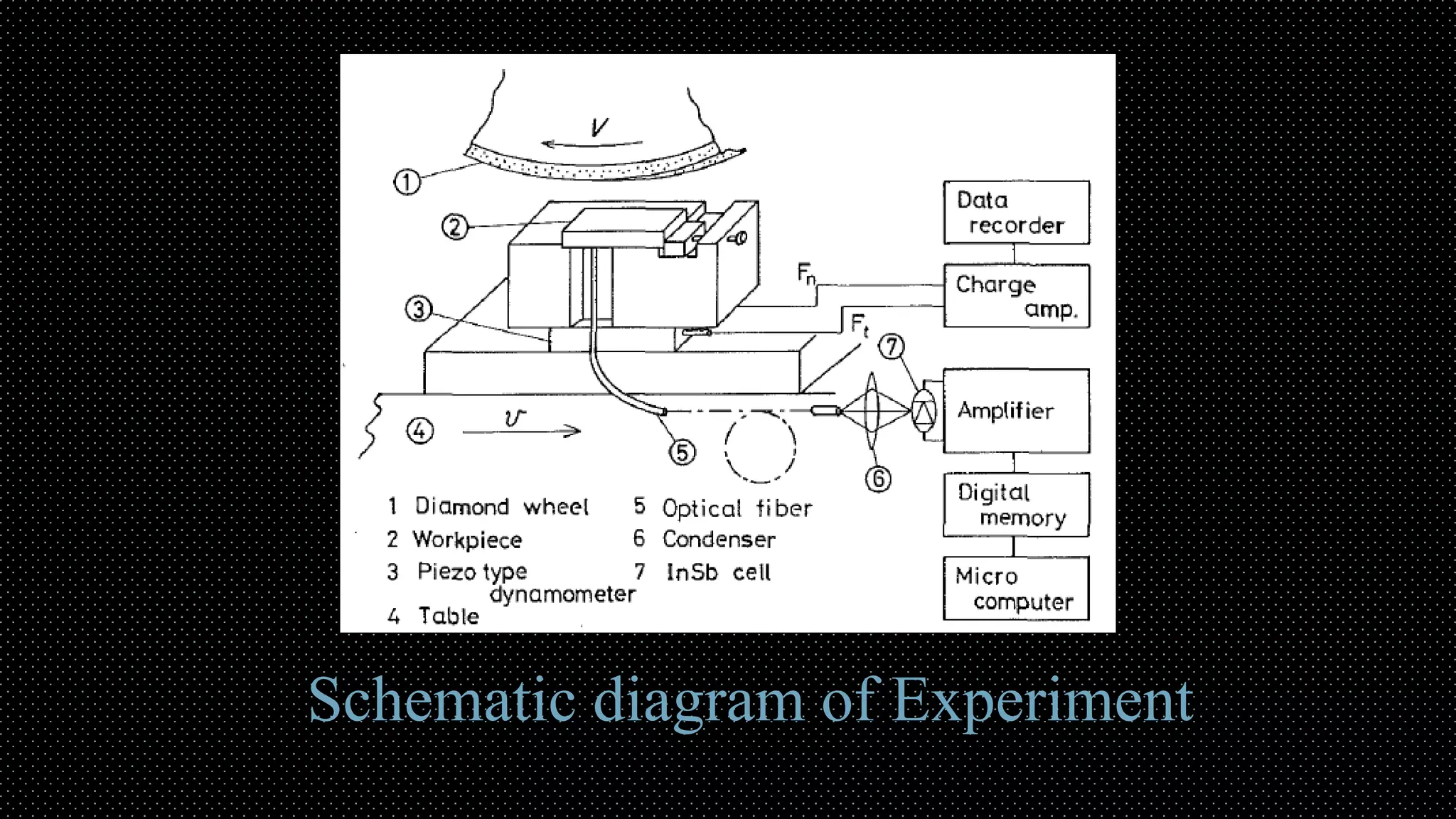

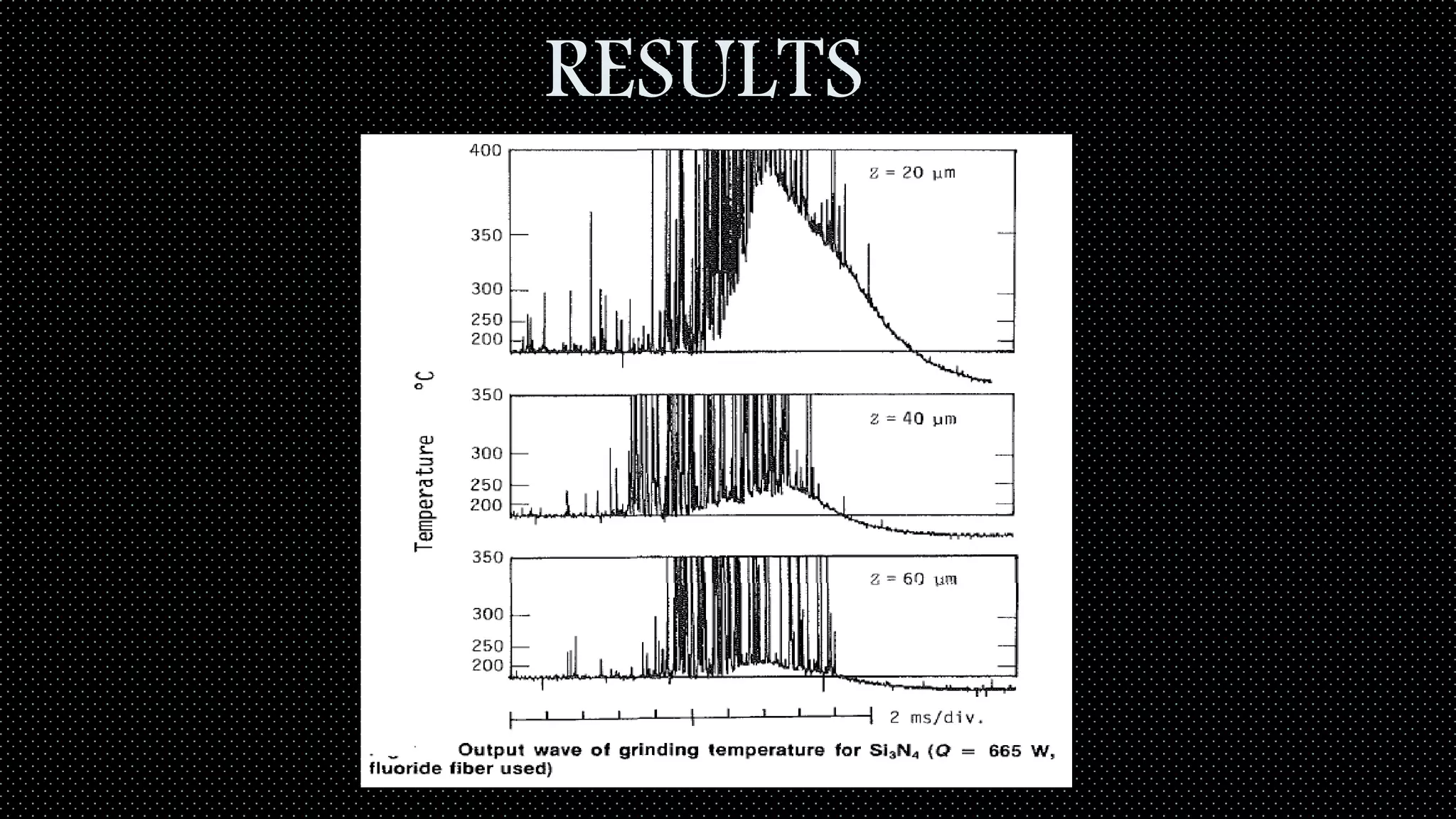

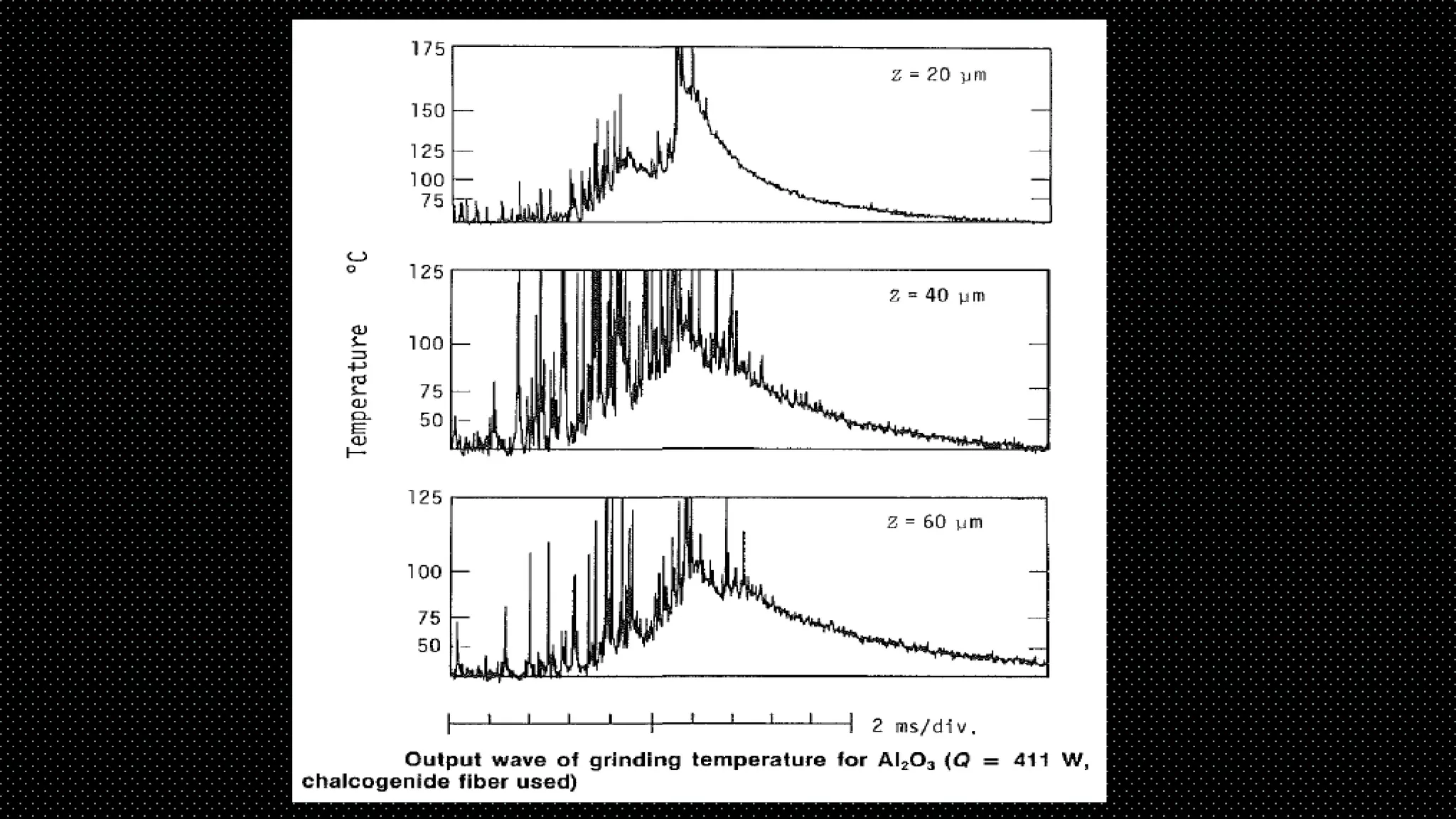

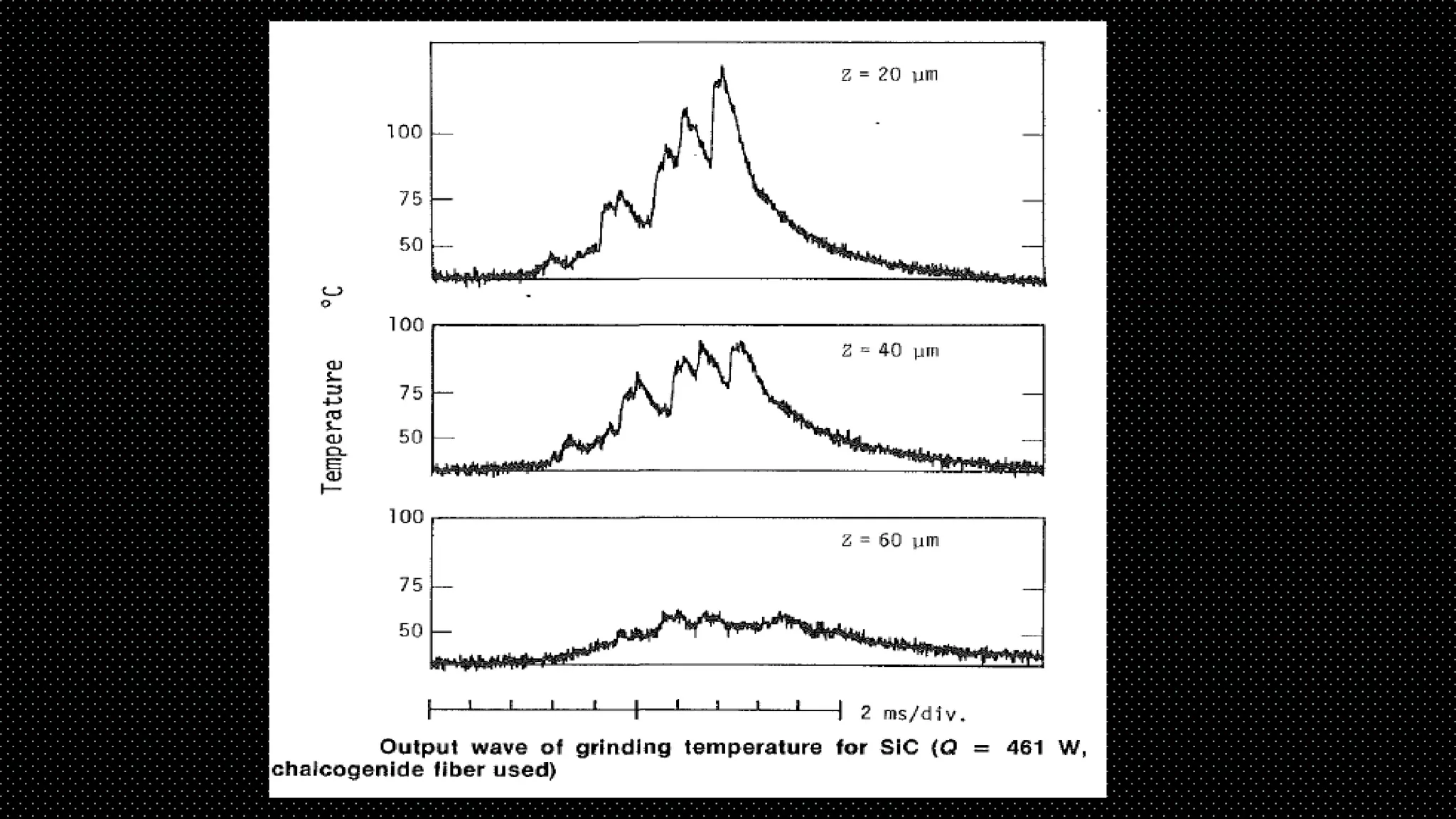

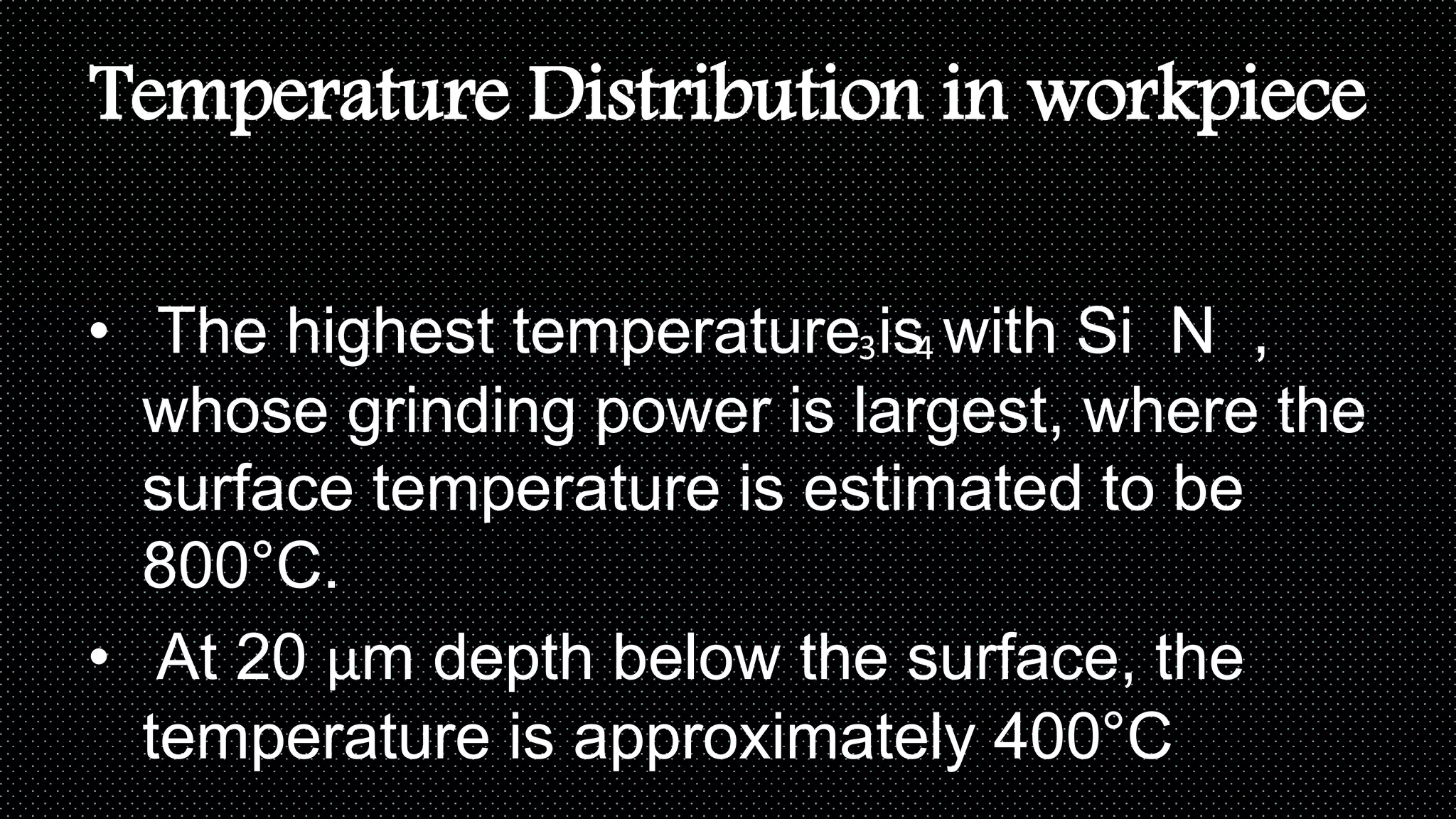

The document explores the measurement of grinding temperature using an infrared imaging system with optical fibers, focusing on the effectiveness of different fiber types. Key findings indicate that the highest surface temperature in grinding ceramics is observed with Si3N4, reaching approximately 800°C, while temperature distributions vary among materials. The study concludes that infrared pyrometers can effectively measure grinding temperatures and highlights the optical properties affecting temperature readings.