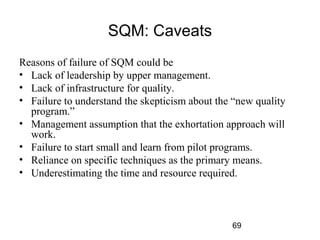

This document provides an introduction to Total Quality Management (TQM). It defines quality, customers, and products. It discusses different perspectives on quality and achieving customer satisfaction. TQM aims to improve quality through a comprehensive organization-wide effort. The document outlines the philosophies of Deming, Juran, and Crosby on TQM. It also discusses quality levels, the history of quality management, process management, control and improvement techniques like statistical process control, Kaizen, flow charts and control charts.