The document presents a project on developing a master-slave robotic arm powered by wireless energy transmission, using Arduino technology for control and synchronization between the master's movements and the slave arm. The project aims to enhance human-robot interaction through gesture recognition, while improving efficiency in power transmission, addressing significant energy losses associated with traditional methods. The research also delves into the design and operational methodologies required for effective robotic manipulation and wireless power implementation.

![INTRODUCTION

1.0 Introduction

Interpretation of master slave system is used for human-machine interaction in

the area of robotics. The main purpose of master slave system research is to identify

and give a particular human movement and convey information to the robot pertaining

to individual movement. Specific movement of interest can be given, and on the basis of

that, specific command for execution of action can be given to robotic system. Overall

aim is to make the microcontroller understand human body language, thereby bridging

the gap between machine and human. Hand gesture recognition can be used to

enhance human–machine interaction without depending on traditional input devices

such as keyboard and mouse. Hand gestures are extensively used for telerobotic

control applications. Robotic systems can be controlled naturally and intuitively with

such telerobotic communication. A prominent benefit of such a system is that it presents

a natural way to send geometrical information to the robot such as: left, right, etc.

Robotic hand can be controlled remotely by hand movements. Research is being

carried out in this area for a long time. Several approaches have been developed for

sensing hand movements and controlling robotic hand. Glove based technique is a well-

known means of recognizing hand gestures. It utilizes sensor attached mechanical

glove devices that directly measure hand and/or arm joint angles and spatial position.

Although glove-based gestural interfaces give more precision, it limits freedom as it

requires users to wear cumbersome patch of devices. Technologists have used entropy

analysis to extract hand region in complex background for master slave robotic system.

Robot controlling is done by fusion of hand positioning and arm gestures using dummy

arm. Although it gives more precision, it limits freedom due to necessity of dummy arm

movement. For capturing hand gestures correctly, proper pots and angles are required.

The problem of précised position recognition and tracking is quite challenging. Many

early approaches used lengthy programming and different codes to make the problem

of position recognition easier, but due to their inconvenience, they cannot be considered

as a natural interface for the robot control. The use of specific pots, servos and arduino

microcontroller board could be the best solution for this as arduino can be coded in

higher level languages. It can be extended to any robotic system with a number of

specific commands suitable to that system.

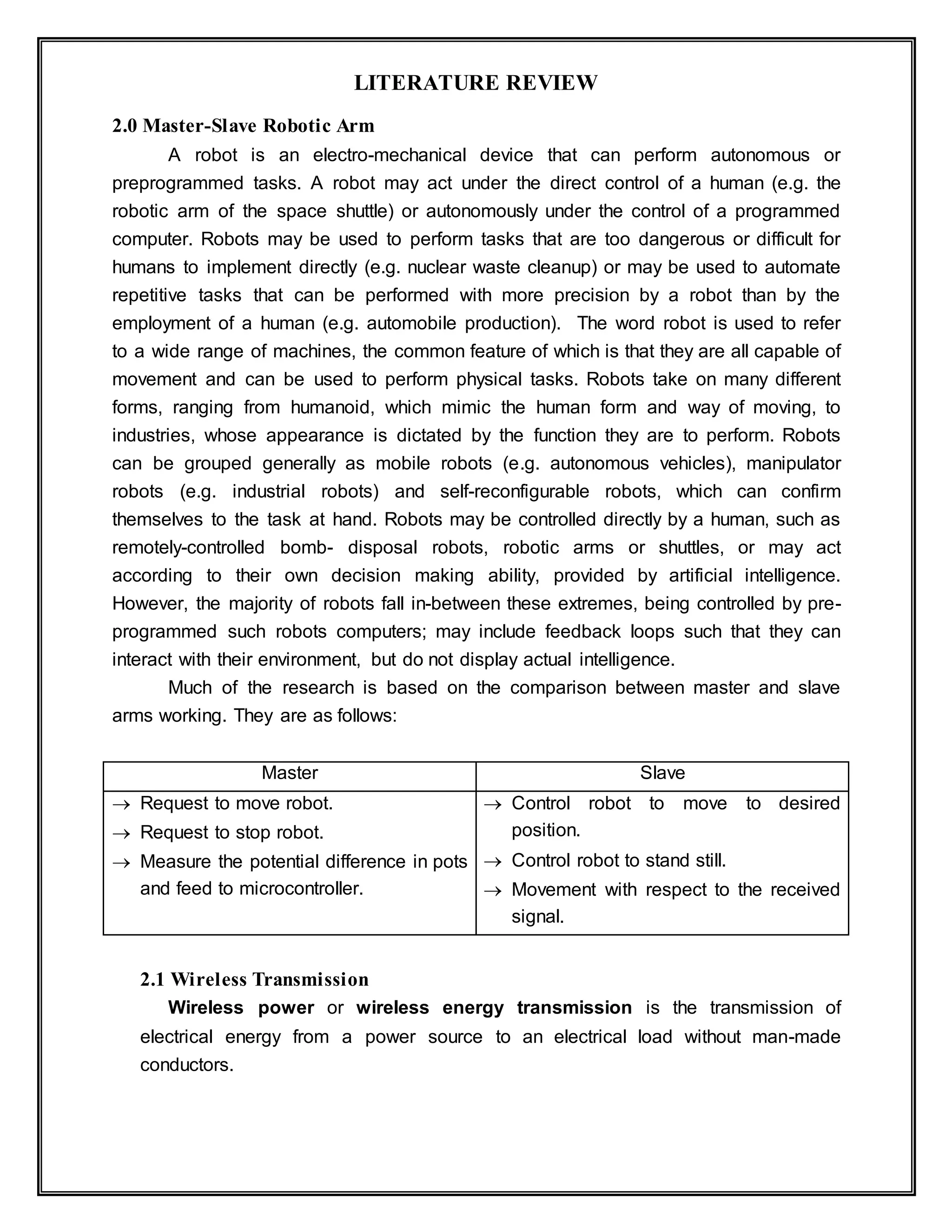

One of the major issue in power system is the losses occurs during the

transmission and distribution of electrical power. As the demand increases day by day,

the power generation increases and the power loss is also increased. The major

amount of power loss occurs during transmission and distribution. The percentage of

loss of power during transmission and distribution is approximated as 26%. The main

reason for power loss during transmission and distribution is the resistance of wires

used for grid. The efficiency of power transmission can be improved to certain level by

using high strength composite overhead conductors and underground cables that use

high temperature super conductor. But, the transmission is still inefficient. According to

the World Resources Institute (WRI), India’s electricity grid has the highest transmission

and distribution losses in the world – a whopping 27%. Numbers published by various

Indian government agencies put that number at 30%, 40% and greater than 40%. This

is attributed to technical losses (grid’s inefficiencies) and theft [1]. Any problem can be

solved by state–of-the-art technology. The above discussed problem can be solved by

choose an alternative option for power transmission which could provide much higher

efficiency, low transmission cost and avoid power theft. Microwave Power Transmission](https://image.slidesharecdn.com/synopsisreport-151130110543-lva1-app6892/75/Master-Slave-Robotic-Arm-Using-Wireless-Transmission-Of-electricity-4-2048.jpg)

![REFERENCES

PDF EDITION OF CARL DAVID TODD (ED), "THE POTENTIOMETER

HANDBOOK",MCGRAW HILL, NEW YORK 1975 ISBN 0-07-006690-6

UPSON, A.R; BATCHELOR, J.H. (1978) [1965]. SYNCHRO ENGINEERING

HANDBOOK . BECKENHAM: MUIRHEAD VACTRIC COMPONENTS. PP. 7, 67–90.

ROBOTICS, AUTOMATION AND MECHATRONICS, 2004 IEEE CONFERENCE ON

(VOLUME:1 ) PAGES 37 - 42 VOL.1 ISBN:0-7803-8645-0

HU, A.P. (2009). WIRELESS/CONTACTLESS POWER SUPPLY: INDUCTIVE

COUPLED RESONANT CONVERTER SOLUTIONS, SAARBRUCKEN, GERMANY:

VDM VERLAG, DR. MULLER.

SYSTEM FOR TRANSMISSION OF ELECTRICAL ENERGY, U.S. PATENT NO. 645,576

MARCH 20, 1900.

OWI ROBOTIC ARM EDGE ASIN: B0017OFRCY

BUILD YOUR OWN ROBOTIC ARM LESSON PDF MANUAL.

"PROGRAMMING ARDUINO GETTING STARTED WITH SKETCHES" . MCGRAW-

HILL . NOV 8, 2011. RETRIEVED 2013-03-28.

"THE ARDUINO SOURCE CODE" . THE ARDUINO SOURCE CODE. "POLICY" .

ARDUINO.CC. RETRIEVED 2013-01-18.

WEBSITES

www.arduino.cc

www.wikipedia.com

www.instructables.com

www.societyofrobots.com

www.letsmakerobots.com

www.google.com](https://image.slidesharecdn.com/synopsisreport-151130110543-lva1-app6892/75/Master-Slave-Robotic-Arm-Using-Wireless-Transmission-Of-electricity-13-2048.jpg)