1. Calibrate the line sensor readings by taking multiple samples while turning left and right to determine the minimum and maximum values.

2. Continuously read the line sensor position and calculate the proportional, integral, and derivative terms based on the error from the center.

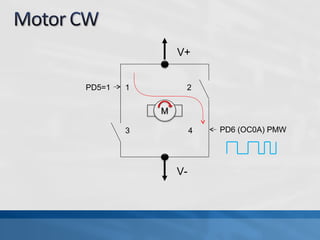

3. Determine the difference in motor powers needed to turn toward the center based on the PID values, without allowing negative powers.

4. Set the motor speeds based on the power difference to steer toward the center line.

![// Introductory messages. The "PROGMEM" identifier causes the data to

// go into program space.

const char welcome_line1[] PROGMEM = " Pololu";

const char welcome_line2[] PROGMEM = "3xf7 Robot";

const char demo_name_line1[] PROGMEM = "PID Line";

const char demo_name_line2[] PROGMEM = "Follower";

// A couple of simple tunes, stored in program space.

const char welcome[] PROGMEM = ">g32>>c32";

const char go[] PROGMEM = "L16 cdegreg4";A](https://image.slidesharecdn.com/avr-121107134144-phpapp01/85/AVR-Fundamentals-84-320.jpg)