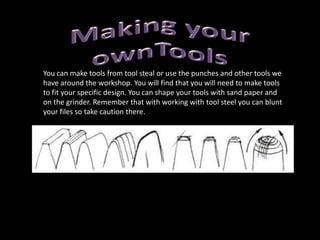

This document discusses various tools used in repoussé metalworking including liners, modeling punches, planishing punches, matting punches, and setting punches. It describes how to make your own tools from tool steel and shape them using sandpaper and a grinder. The document provides instructions for the repoussé process including preparing the metal, transferring the design, working the metal in pitch, and potential issues like overworking the metal. It stresses safety precautions like eye protection, ventilation, and maintaining tools to prevent risks during this metalworking process.