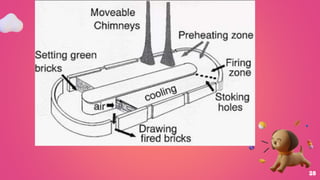

The document summarizes the process of manufacturing bricks which involves four main steps: 1) preparation of clay by cleaning, weathering, blending and tempering the clay; 2) molding the clay into bricks by hand or machine; 3) drying the molded bricks naturally or artificially; and 4) burning the dried bricks in clamps, intermittent kilns or continuous kilns like bull's trench kilns or Hoffman's kilns to harden them. The burning process ensures the bricks gain strength and hardness at around 1100°C.