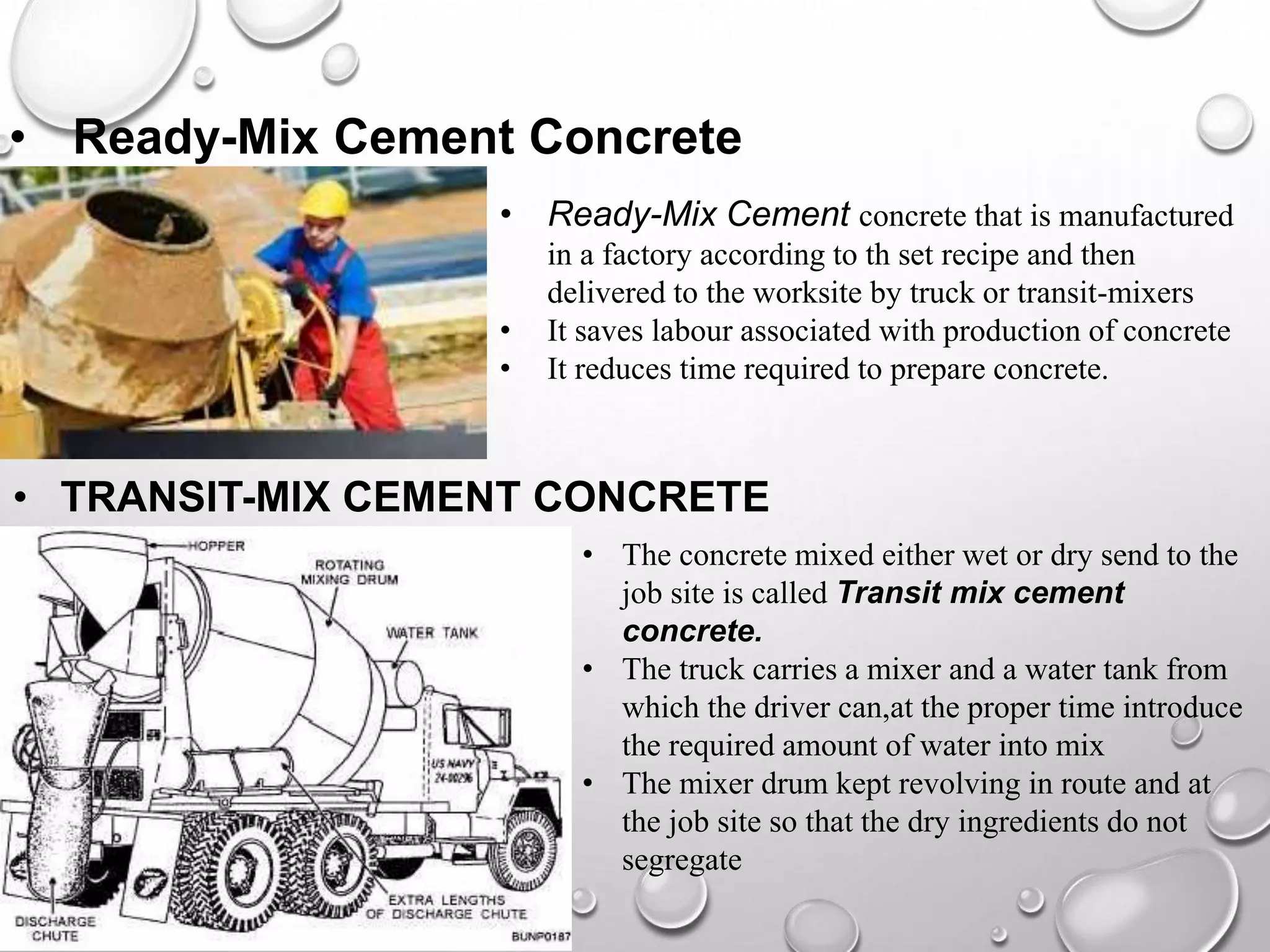

Cement concrete is a mixture of cement, aggregates, and water that hardens into a strong building material, notable for its compressive strength and resistance to atmospheric agents. The document discusses various types and proportions of concrete mixes, the properties of cement and aggregates, and the importance of proper curing for durability. Additionally, it describes the benefits of using concrete for different applications, including precast and ready-mix concrete options.