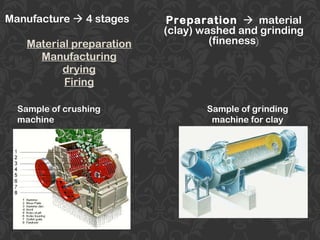

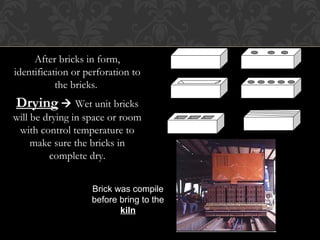

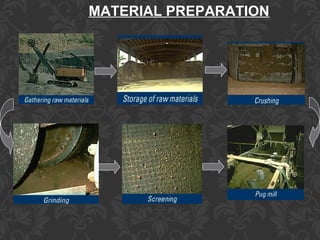

Bricks are manufactured through one of four processes - molded, extruded, pressed, or hand-formed. The manufacturing process involves preparing raw clay materials, forming the bricks, drying them, and firing them in kilns. Different types of bricks include mud bricks, mud-cement bricks, burnt bricks, and cement blocks. Bricks have a variety of structural and decorative uses in buildings, furnaces, pavements, and other construction.