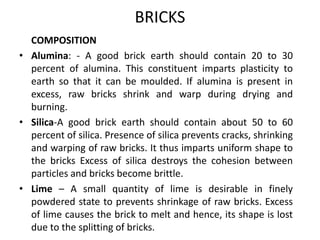

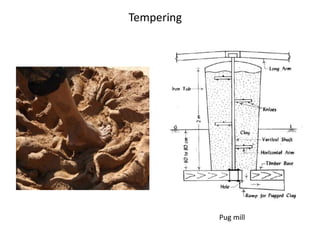

This document discusses the process of manufacturing bricks. It begins by describing the composition of bricks, noting that good bricks should contain 20-30% alumina, 50-60% silica, and small amounts of lime, iron oxide, and magnesia. The document then outlines the key steps in brick manufacturing: preparation of clay, moulding, drying, and burning. Moulding can be done by hand or machine, drying takes 3-10 days, and burning involves dehydration, oxidation and vitrification to harden the bricks. Proper composition and manufacturing process are necessary to produce durable bricks of consistent quality.