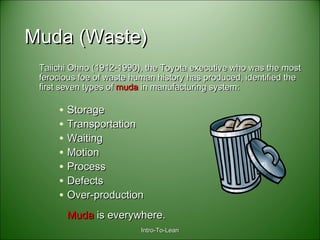

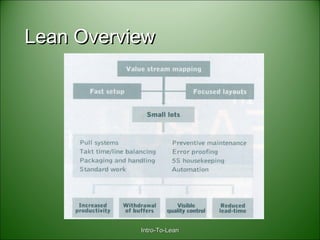

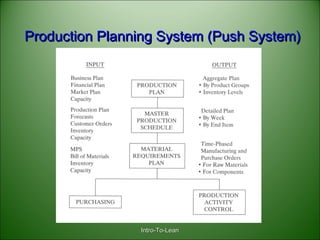

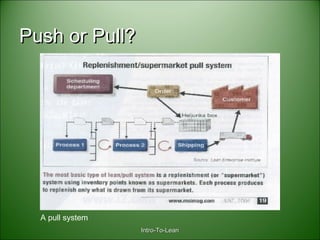

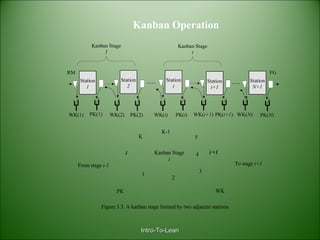

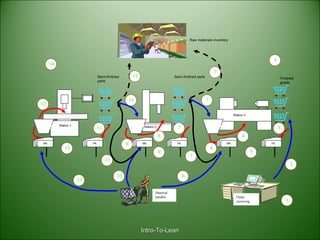

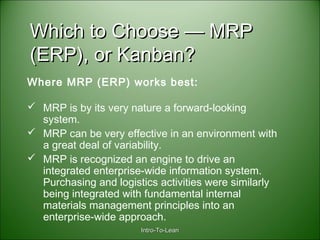

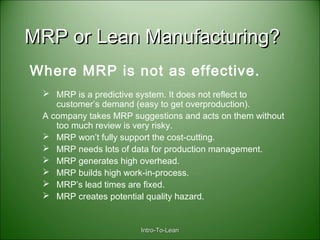

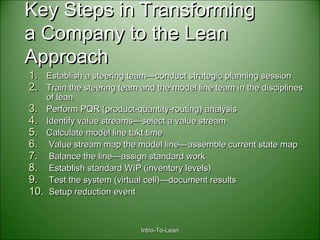

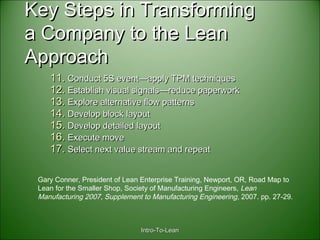

Lean manufacturing is a philosophy and systematic approach that identifies and eliminates waste through continuous improvement. It aims to optimize flow and pull production based on customer demand. Key aspects of lean include just-in-time production, standard work, and using kanban systems to signal when to produce and deliver parts. While MRP systems focus on predictive planning, lean and kanban are more reactive to customer orders through pull-based production. Implementing lean requires transforming processes through tools like 5S, value stream mapping, and setup reduction to optimize efficiency and quality.