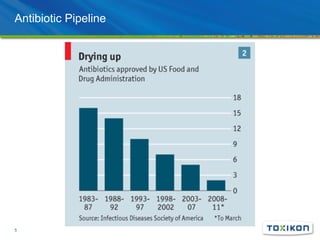

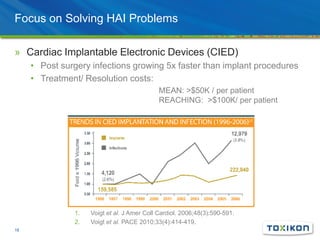

The document discusses strategies for developing multidisciplinary safety and efficacy testing for medical devices and combination products to combat healthcare-associated infections. It highlights the issues of antibiotic resistance and emerging pathogens. Various new product designs and engineering solutions are presented as case studies, along with the need for safety testing that includes biocompatibility, microbiology, chemical characterization, and toxicology. Regulatory requirements and guidelines for combination products involving drugs or biologics are also reviewed.

![Premarket Notification [510(k)] Submissions for Medical

Devices that Include Antimicrobial Agents

Recomendations

» Determine biocompatibility & toxicological affect of device to patient

» Determine the safe levels of the Antimicrobial Agent (NOAEL)

» Ensure that the integration of the Antimicrobial Agent with the device is

still safe (this is not considered additive, but multiplicative).](https://image.slidesharecdn.com/toxikon-150306165827-conversion-gate01/85/Innovative-Medical-Devices-Developing-Multidisciplinary-Safety-Efficacy-Testing-Strategies-for-Combination-Products-36-320.jpg)

![Premarket Notification [510(k)] Submissions for Medical

Devices that Include Antimicrobial Agents

Recomendations

» Low levels of toxic leachates exposed to patient with Antimicrobial

Agent may result in new safety concerns.

» Ensure the interaction of leachates & degradants from device are non-

reactive with eluted antimicrobial agent & it’s degradation components.

» Ensure antimicrobial loading is sufficient to demonstrate improved

efficacy](https://image.slidesharecdn.com/toxikon-150306165827-conversion-gate01/85/Innovative-Medical-Devices-Developing-Multidisciplinary-Safety-Efficacy-Testing-Strategies-for-Combination-Products-37-320.jpg)