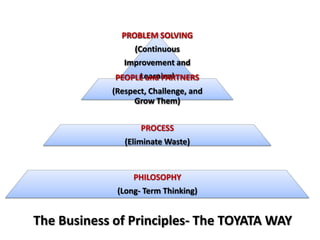

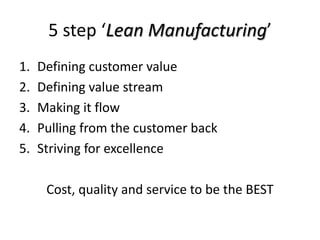

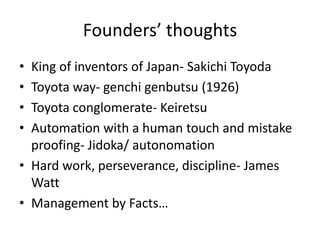

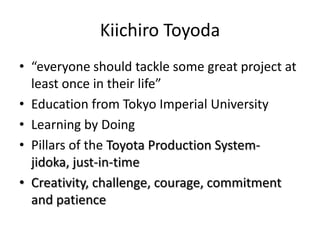

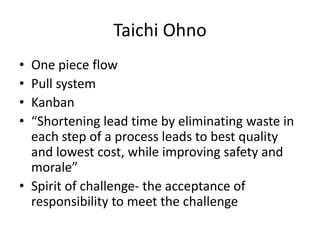

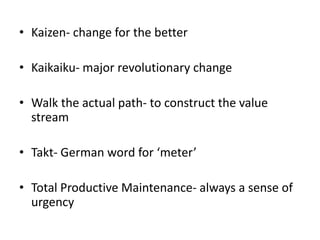

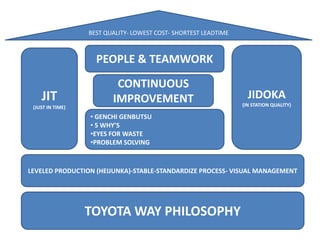

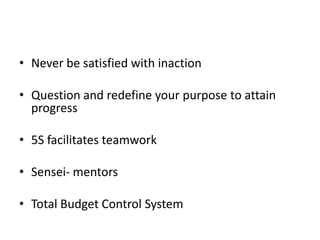

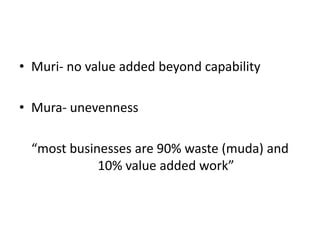

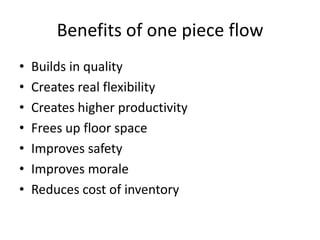

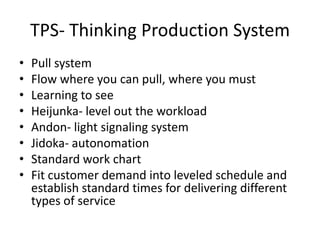

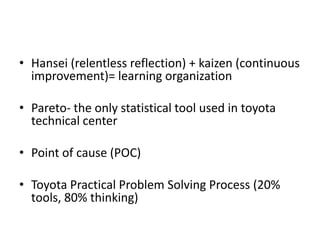

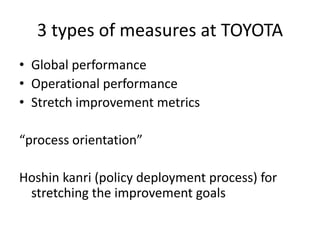

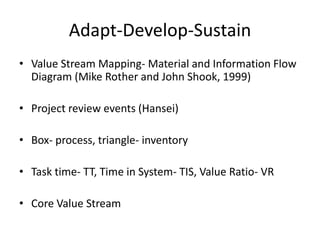

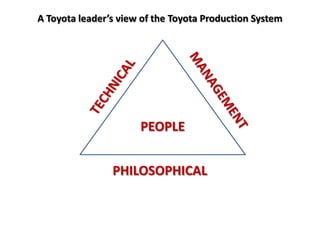

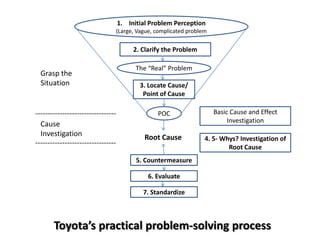

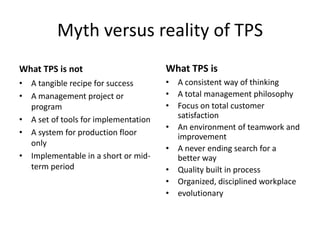

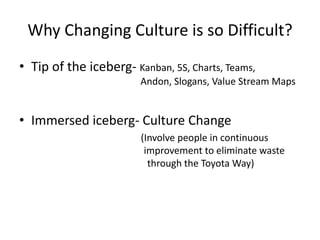

The document summarizes the key principles of the Toyota Production System. It describes Toyota's philosophy of continuous improvement, respect for people, and eliminating waste. The core goals of Toyota's approach are achieving the highest quality at the lowest cost and shortest lead times. Toyota relies on principles like just-in-time production, respect for people, challenging assumptions, and solving problems at their root cause. Overall, the document outlines Toyota's management methods that prioritize operational excellence, continuous learning, and developing a culture of improvement.