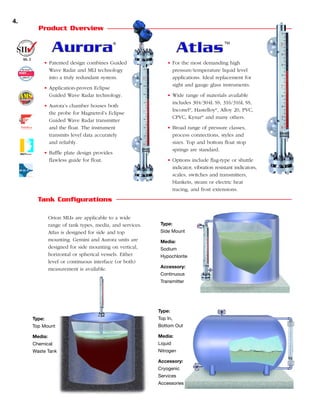

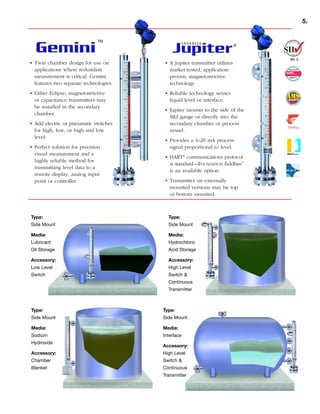

Orion Instruments, a subsidiary of Magnetrol, specializes in advanced magnetic level indicators (MLIs) designed to set new standards in level measurement and control. Their products feature a unique float design, combining magnetic indication with guided wave radar technology for enhanced precision and reliability in various applications, particularly in the petrochemical industry. Orion ensures high-quality manufacturing and offers extensive customization options to meet diverse customer needs.