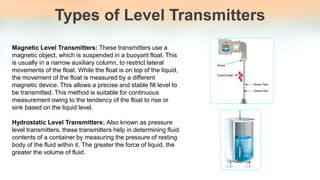

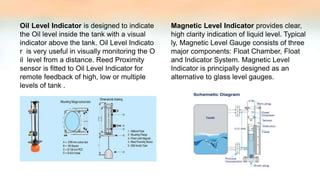

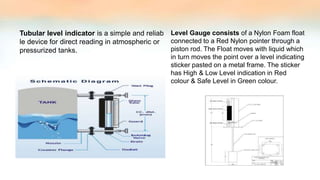

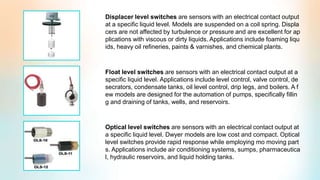

This document provides an overview of various types of level sensors and transmitters used for measuring liquid and bulk-solid levels in industrial applications. It details different technologies such as capacitance, ultrasonic, radar, and magnetic level transmitters, as well as several types of level switches. The content also covers specific applications and industries in which these devices are commonly utilized.