This document contains summaries of various products and technologies for powder and bulk solids handling. It discusses mercury intrusion porosimeters that can accurately measure pore size distributions and densities. It also mentions a patented bulk bag material conditioner that can return solidified materials to a free-flowing state and a silo weight monitoring and control system that can predict when refills are needed to avoid shutdowns. The document provides brief summaries of these various powder and bulk solids handling products and technologies.

![www.PowderBulkSolids.com 23

August2014

TechnologyReview

Patented design delivers superior performance

Searching for the best equipment? Take a closer look at

the features of our Material Master™ Discharger:

O Patented technology

O ([FOXVLYHGXVWWLJKWDQGÀRZHQKDQFHPHQWRSWLRQV

O /RVVLQZHLJKWRUJDLQLQZHLJKWVVWHPV

O 0RGXODUGHVLJQFXVWRPL]HGIRURXUDSSOLFDWLRQ

O 6WDLQOHVVVWHHORUFDUERQFRQVWUXFWLRQWRRXUVSHFL¿FDWLRQ

O 8QPDWFKHGTXDOLWVHUYLFHLQWHJULWDQGYDOXH

MATERIAL MASTER ™

BULK BAG DISCHARGER

Dust Collection Air Pollution Control

ProductFocus

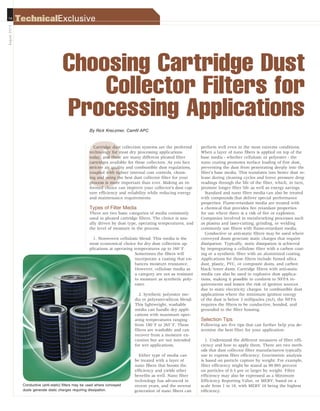

SplitStream Counter Cyclonic Dust Collector

The SplitStream is a counter-cyclonic dust collec-

tor that has no major moving components and is

capable of handling a wide range of materials, all

while requiring minimal maintenance. Its design

ensures that a minimal amount of particulate

comes in contact with the interior walls of the col-

lector. This eliminates excess wear and enables

the collection of abrasive particulate. Unlike other

cyclonic dust collectors, the SplitStream can be

configured in both vertical and horizontal designs.

With a wide range of sizes and installation options,

it is ideal for nearly any plant space layout. The

versatility of this counter-cyclonic dust collector

means lower installation costs and lower mainte-

nance. It is ideal for wet, sticky, or hydroscopic

applications and fibrous dust that would typically

bind or cause issues with fabric filters.

Aerodyne Environmental, Chagrin Falls, OH

800-358-7546 www.dustcollectorhq.com

Capturing Bulk Transported Lime Dust

Weekly tanker truck deliveries of hydrated

lime are pneumatically conveyed to an outdoor

storage bin (silo). A dust collector is required

to allow the conveying air to exhaust, without

pressurizing the silo and preventing any of the

conveyed lime from escaping and discharging

to the environment. Sternvent manufacturers

a bin vent-style dust collector with a flanged

open bottom for mounting on the roof of the

silo. It is available in jet-pulse filter bag and car-

tridge styles, as well as filter bag with automatic

shaker. Options include: a top-mounted, direct-

drive 5-hp blower; internal safety grating; motor

controller; mounting transition to allow easy

retrofit of a new bin vent dust collector to an

existing silo and RAL color match to silo.

Sternvent, Union, NJ 800-383-3878

www.sternvent.com

www.

.com

Check out our

Dust Collection

Air Pollution

Control

Equipment Zone

for the latest

articles,

equipment,

and news

PowderBulkSolids.com

Check out our

Equipment Zones

for news and articles

at PowderBulkSolids.com

Division of Control Concepts,Inc.

www.AirsweepSystems.com

ES466326_PB1408_023.pgs 07.16.2014 21:18 UBMblackyellowmagentacyan](https://image.slidesharecdn.com/352484-powderbulksol-140731234721-phpapp02/85/Powder-Bulk-Solids-Magazine-23-320.jpg)