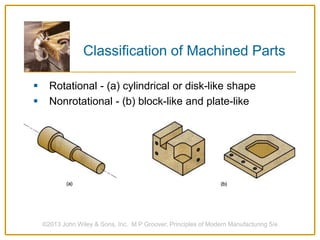

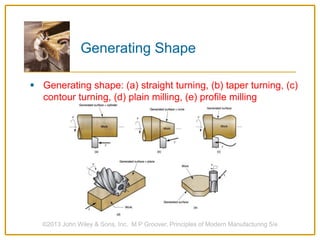

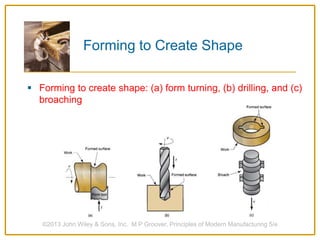

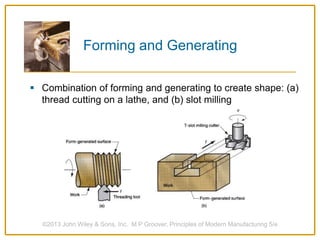

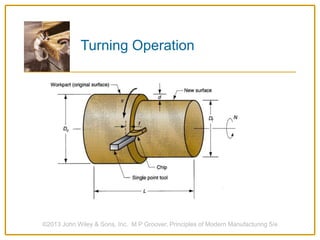

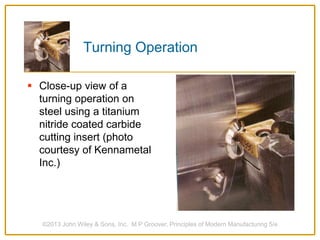

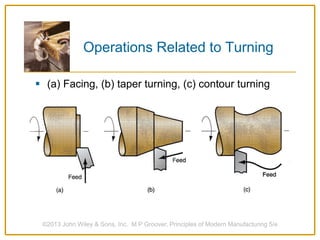

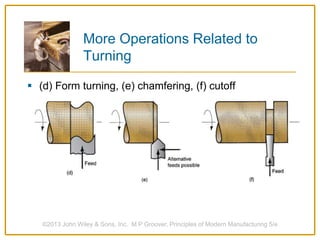

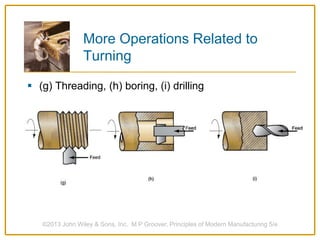

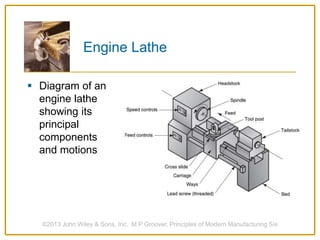

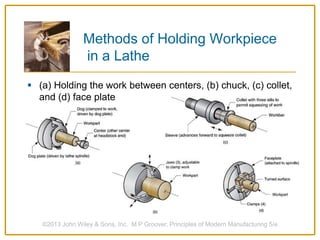

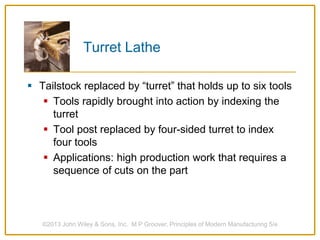

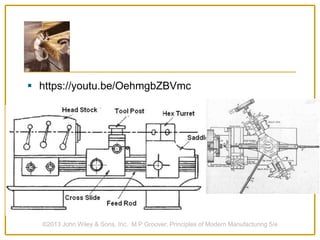

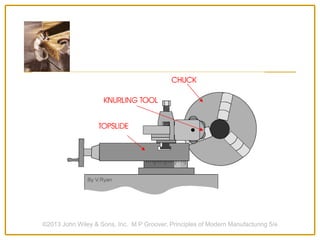

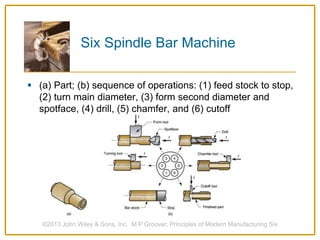

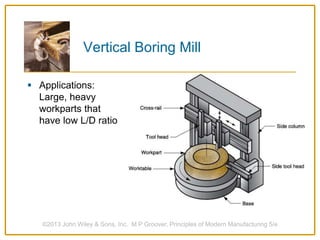

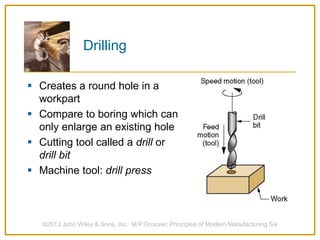

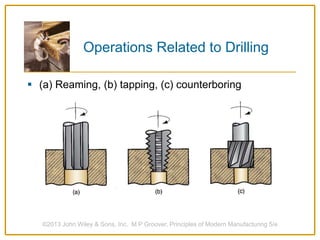

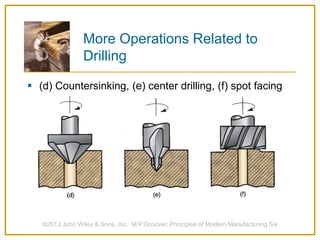

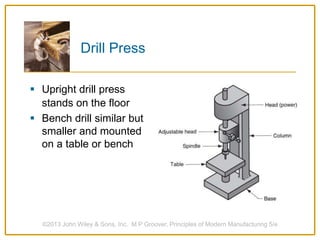

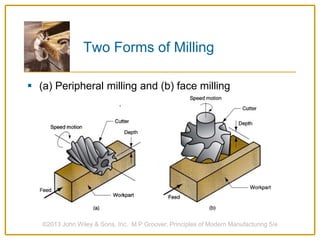

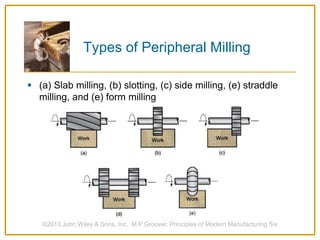

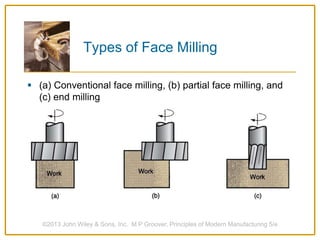

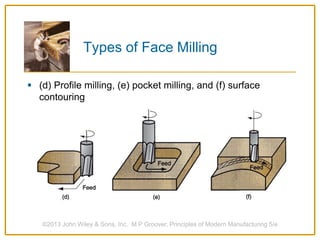

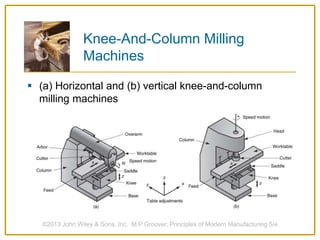

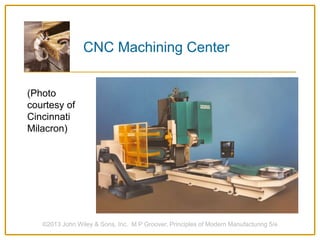

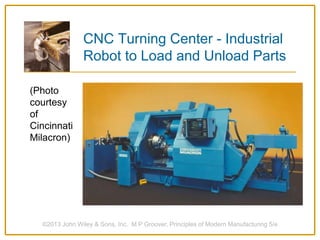

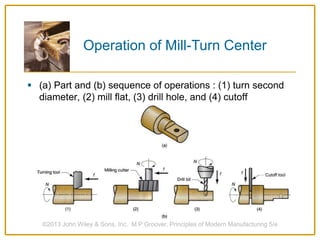

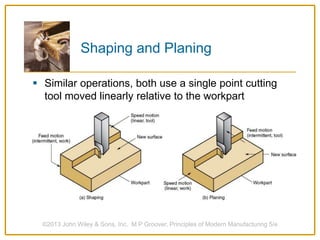

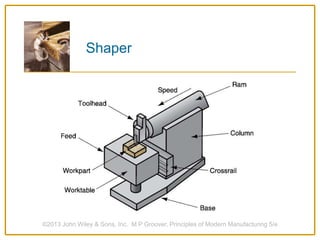

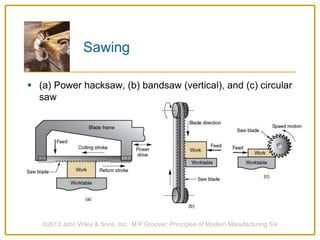

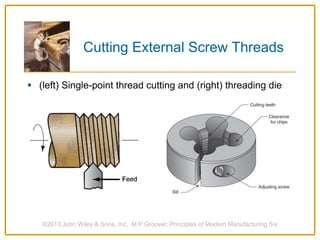

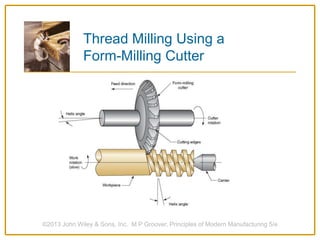

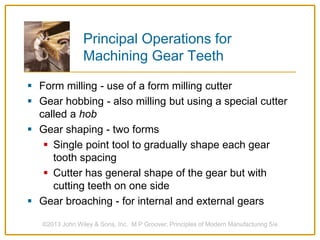

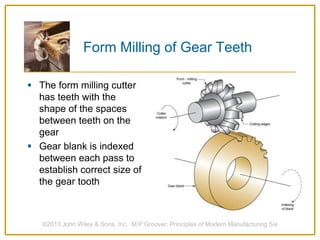

The document discusses various machining operations and machine tools used to manufacture parts through material removal. It describes operations like turning, drilling, milling and others used to produce features like holes, threads, and gears. Specific machine tools are covered that are used for operations like lathes for turning, milling machines, drilling machines, and grinding machines for finishing surfaces.