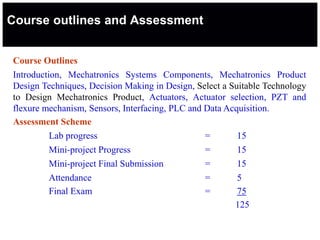

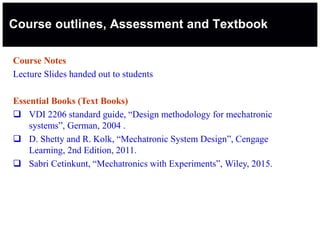

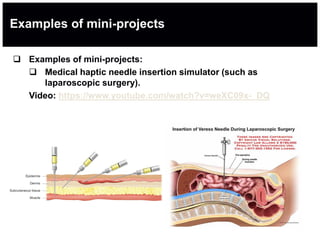

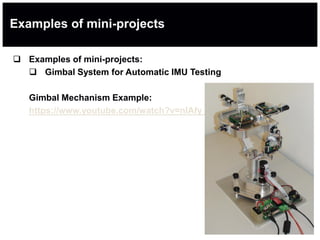

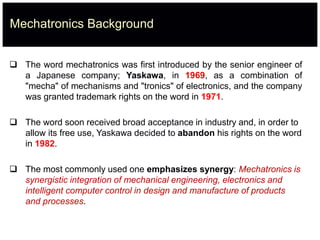

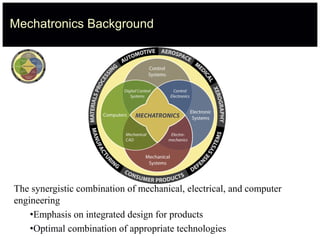

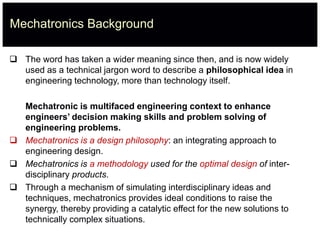

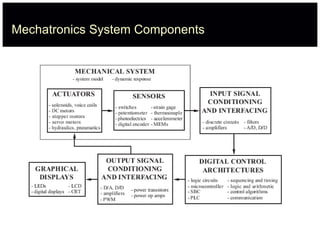

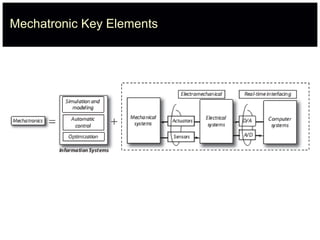

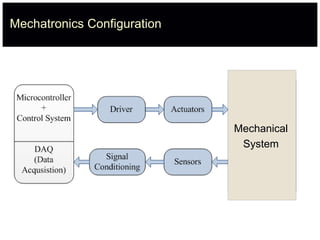

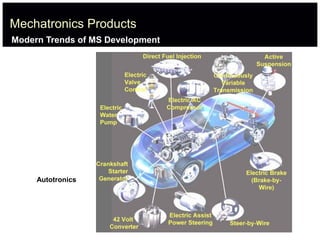

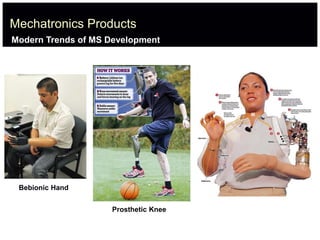

This document outlines a course on mechatronics, including course content, assessment, textbooks, and examples of mini-projects. The course covers topics like mechatronics systems components, product design techniques, actuators, sensors, and PLC and data acquisition. Assessment includes lab progress, mini-project progress and submission, attendance, and a final exam. Examples of mini-projects provided include a medical needle insertion simulator and an adaptive bionic gripper. The document also discusses definitions and background of mechatronics, components of mechatronic systems, and advancements in fields like automotive, biomedical, and aviation applications.