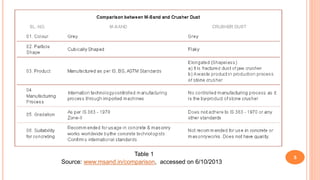

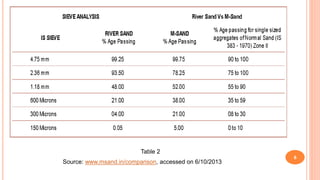

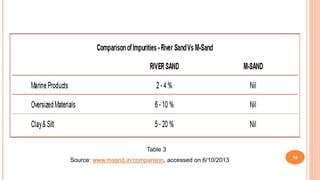

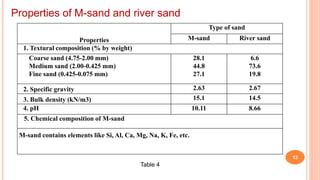

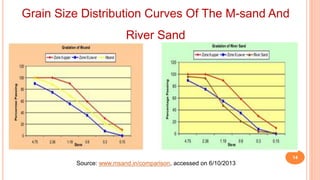

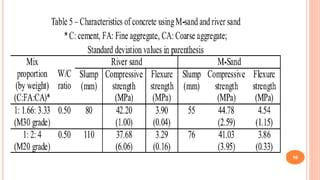

The document discusses the suitability of manufactured sand (M-sand) as a replacement for river sand in concrete. It notes that national authorities have banned river sand mining due to environmental damage and that river sand quality has declined with overexploitation. The document aims to prove scientifically that M-sand performs equal or better than river sand in concrete. It analyzes properties of M-sand and river sand, finding M-sand has better grading and produces concrete with equivalent or better strength and bonding characteristics. The conclusion is that M-sand is a superior substitute for river sand in mortars and concrete.