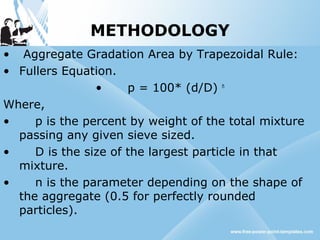

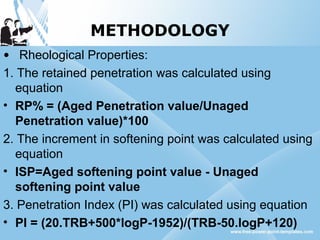

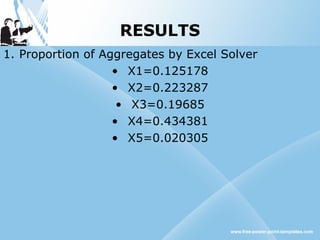

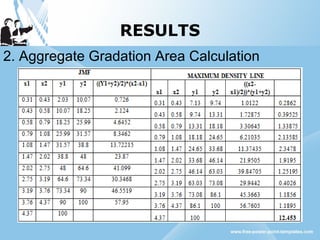

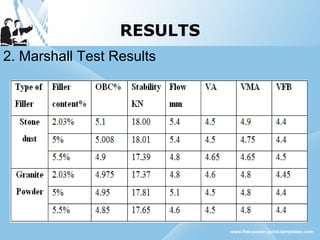

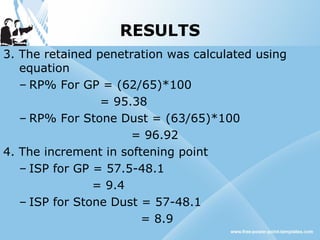

This document presents an analytical method for asphalt concrete mix design using granite powder as filler. It discusses selecting aggregates, developing aggregate gradation models, determining proportions using Excel Solver, estimating gradation areas with Trapezoidal rule, and evaluating mixtures using Marshall stability tests. Test results show granite powder produces comparable properties to stone dust filler and influences aging by increasing stiffness. The method allows quick, accurate mix design optimization.