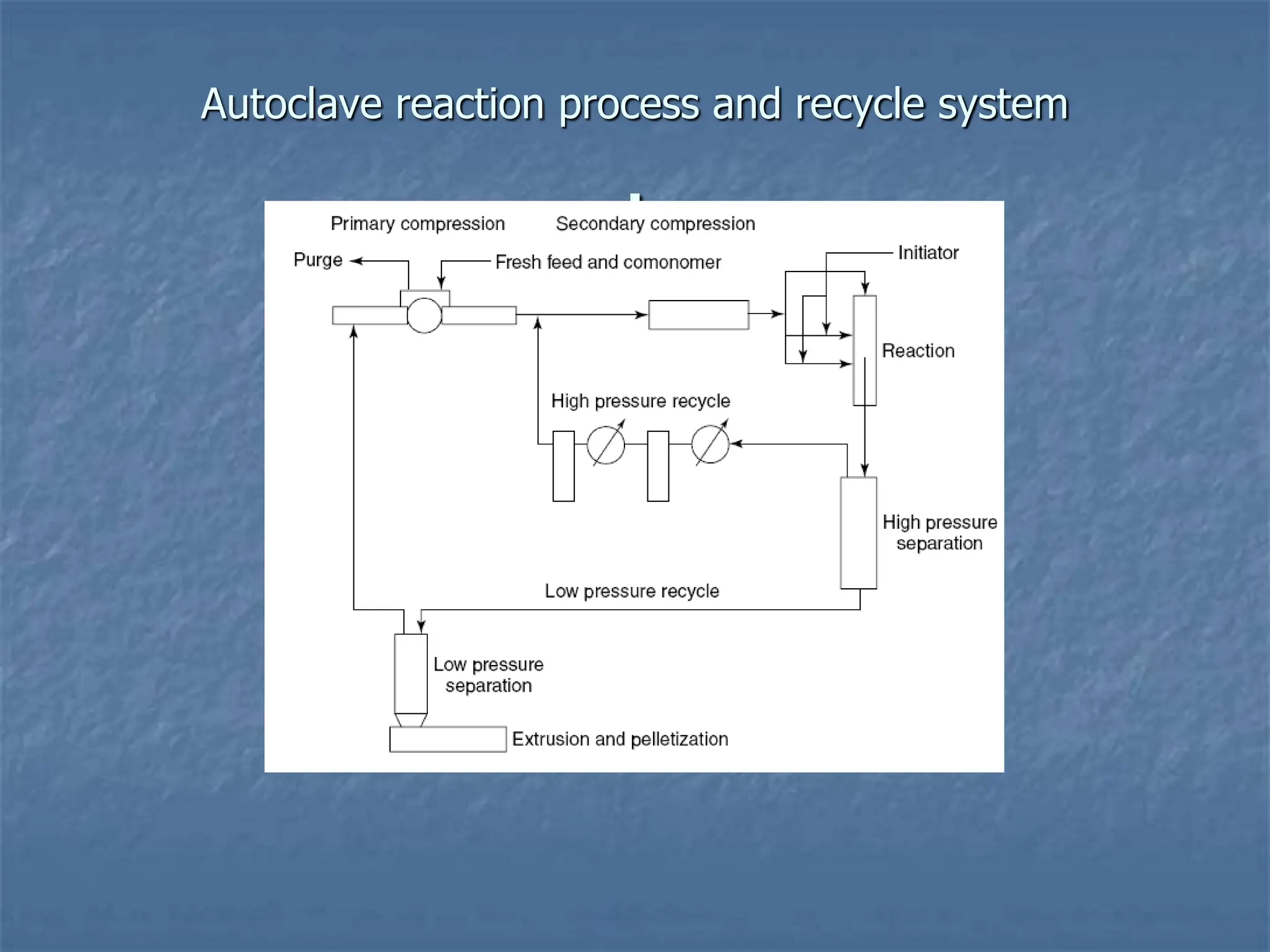

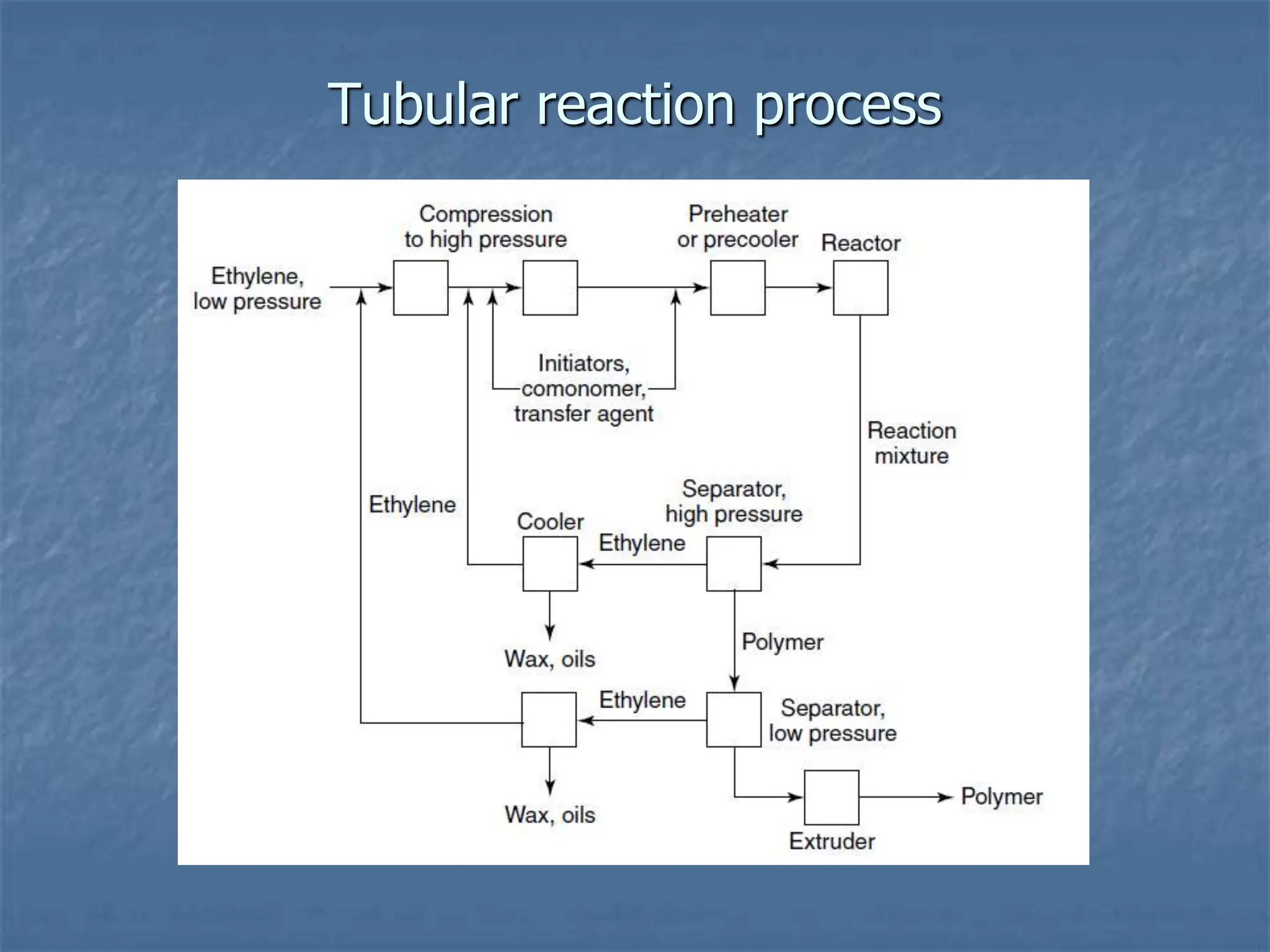

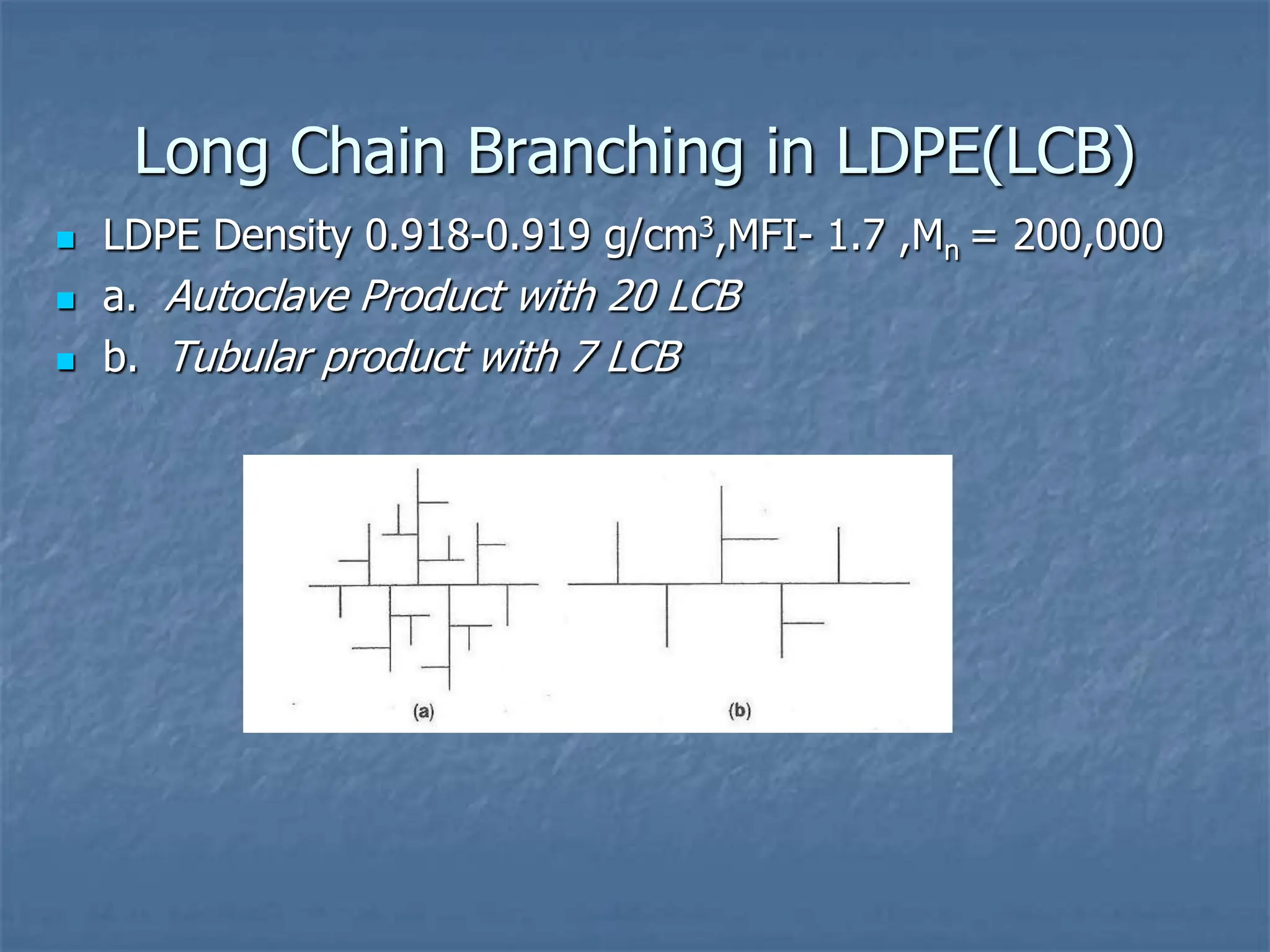

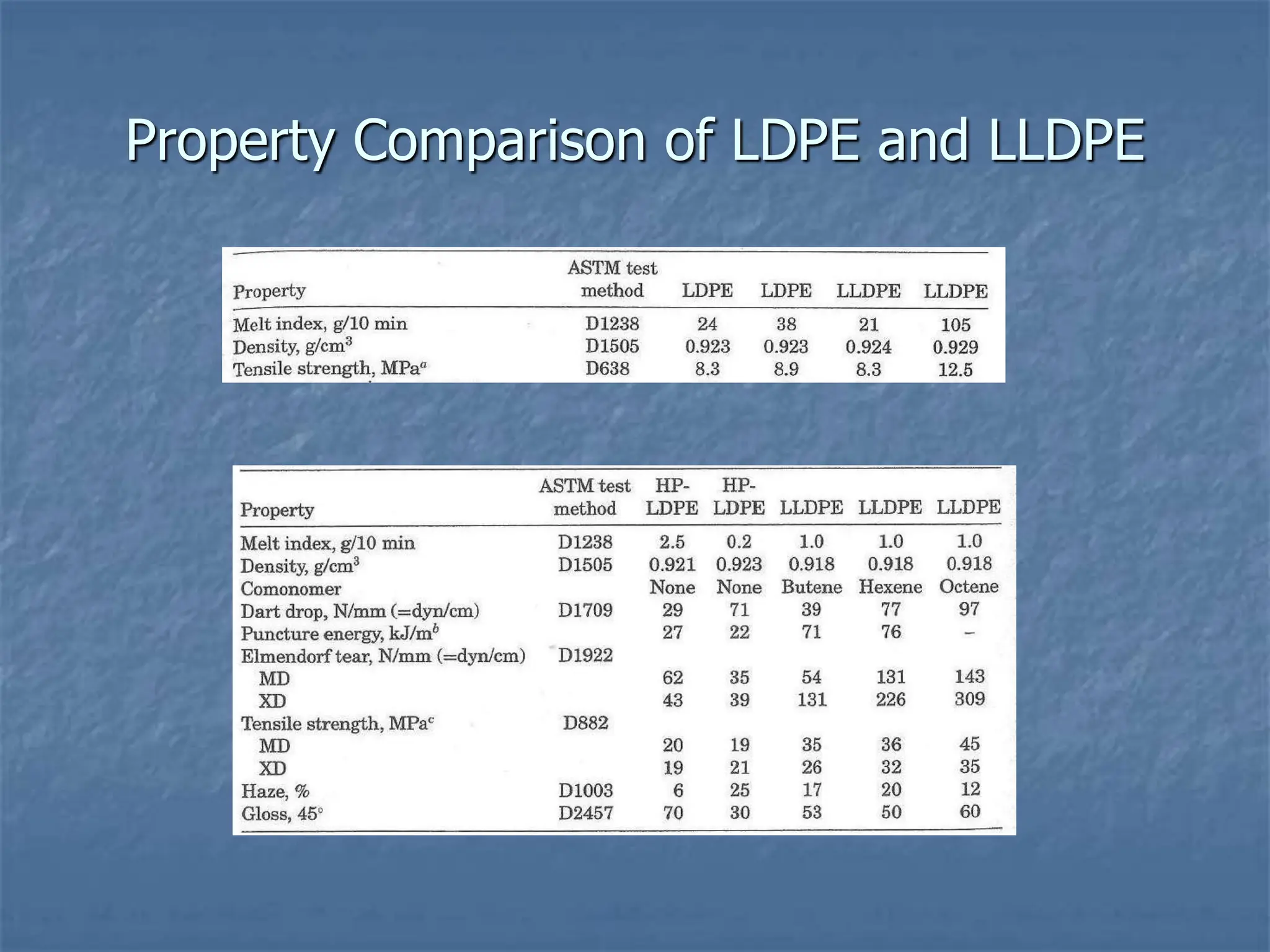

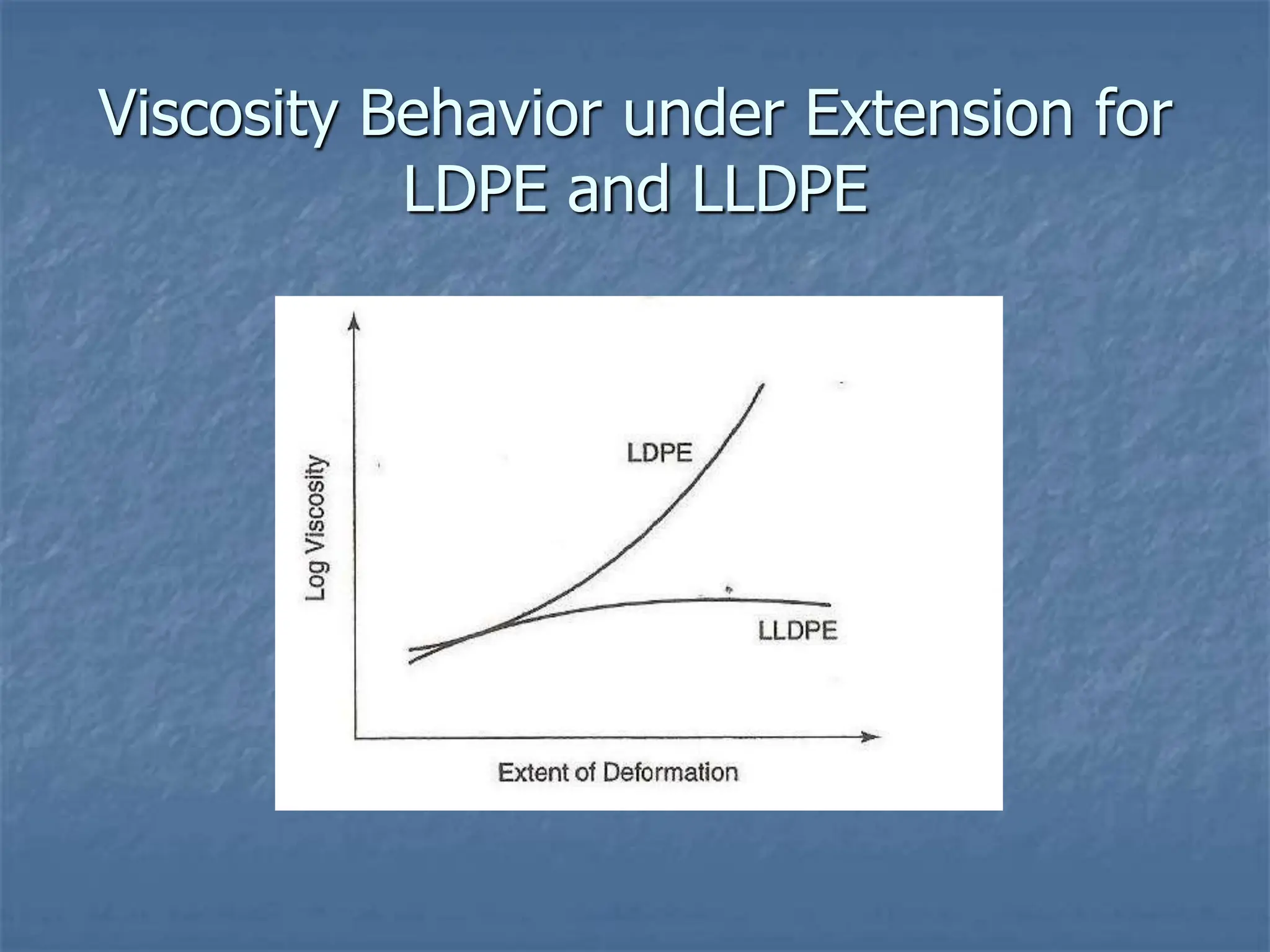

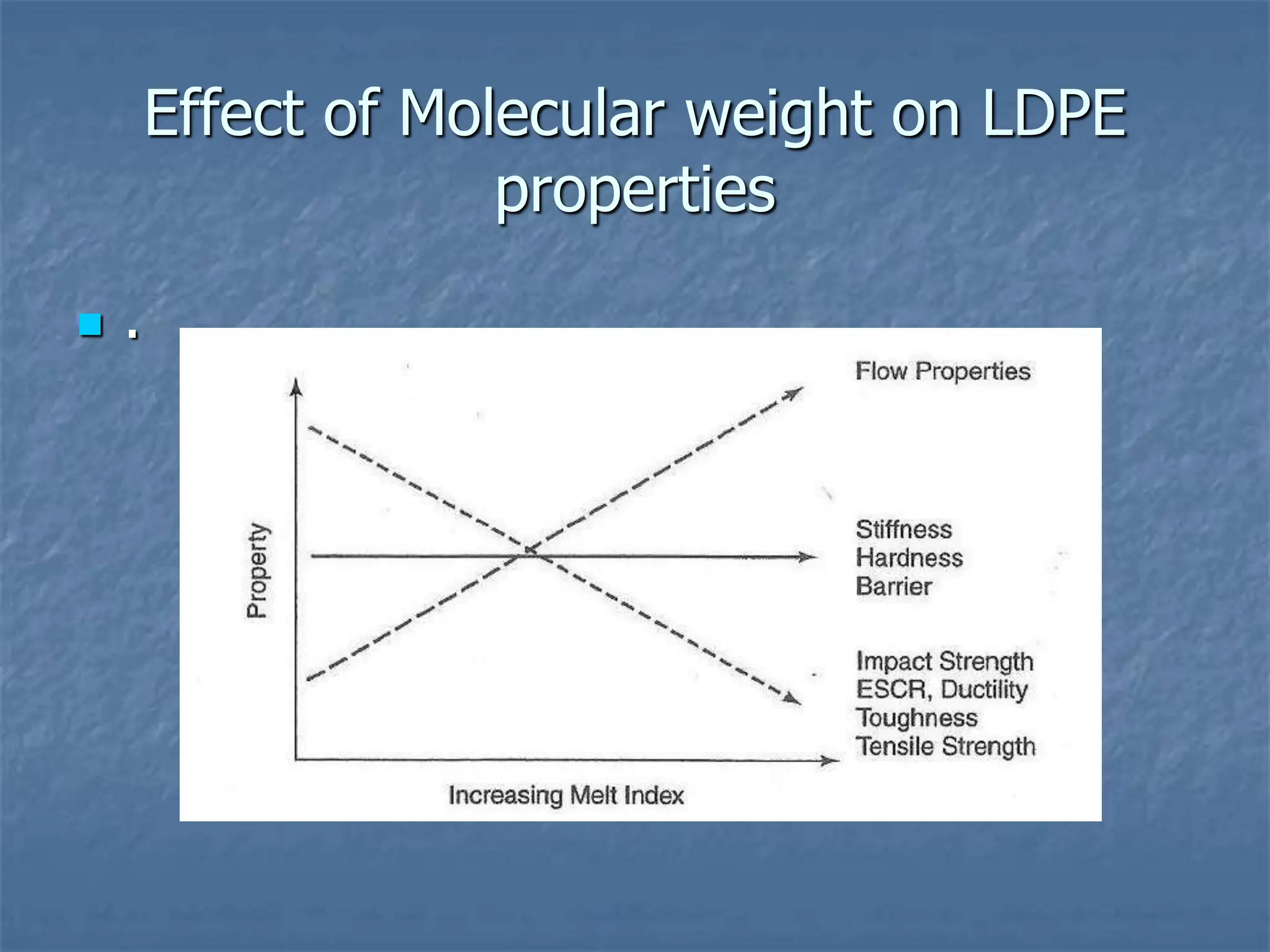

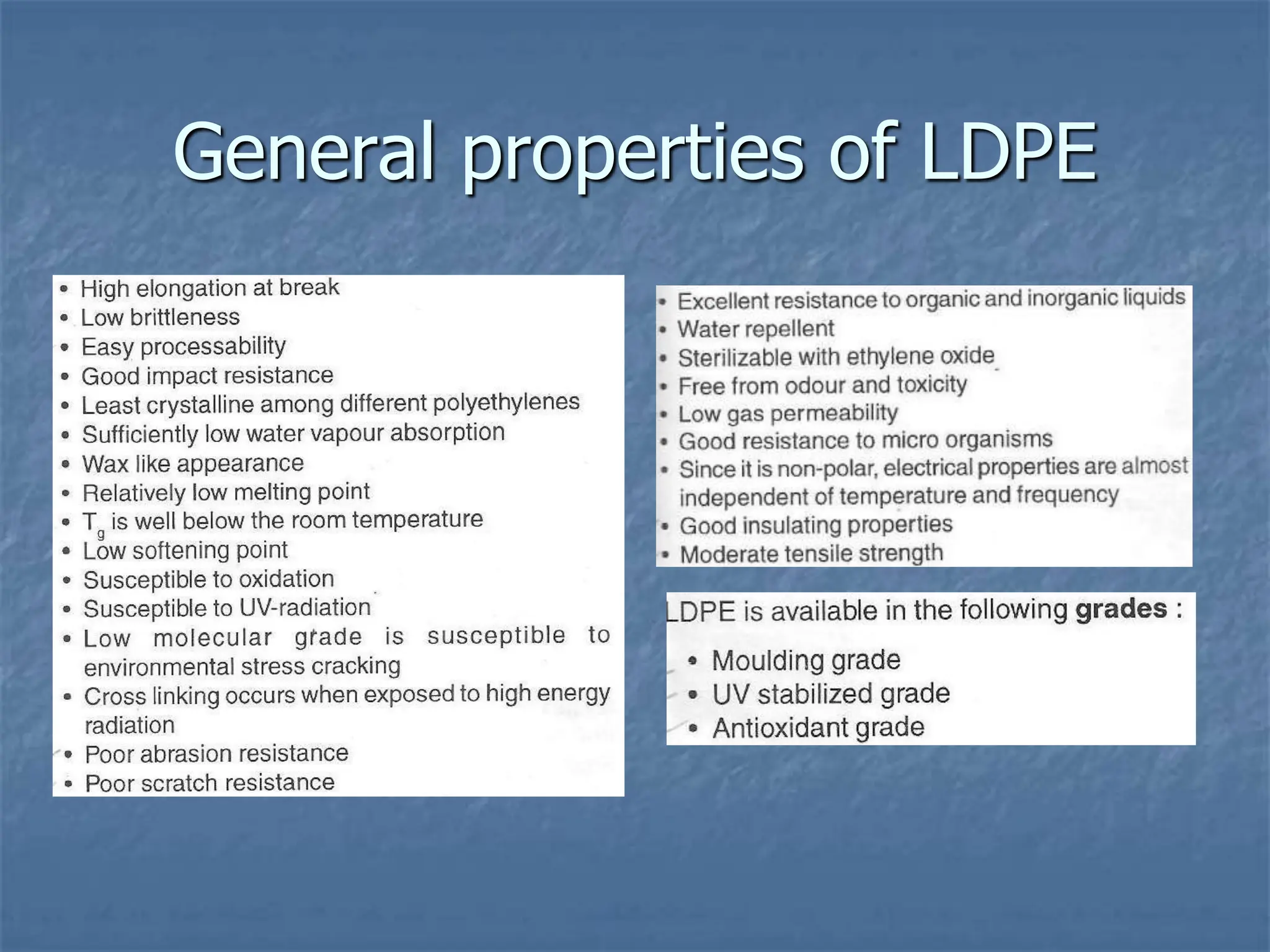

This document discusses low-density polyethylene (LDPE), including its production processes, commercial production technologies, properties, and applications. Specifically, it outlines high and low pressure polymerization processes for producing ethylene. It then describes common LDPE production methods like autoclave and tubular reaction processes. The document also examines properties like long chain branching and viscosity behavior. Finally, it notes key applications of LDPE in areas like film, sheet, shrink wrapping, and extrusion coating for food packaging.