This document summarizes key concepts in logistics and integrated logistics support (ILS), including:

1) Historically, logistics involved supporting military operations through tasks like feeding soldiers, transporting supplies.

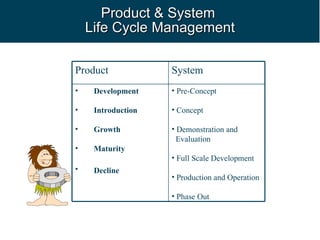

2) ILS takes a unified approach to integrating support considerations into system design from the start to minimize life cycle costs.

3) Key logistics concepts include reliability, maintainability, availability, and life cycle cost analysis. Designing for supportability is important to reducing overall ownership expenses.