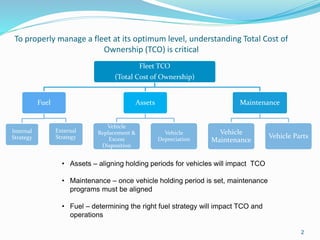

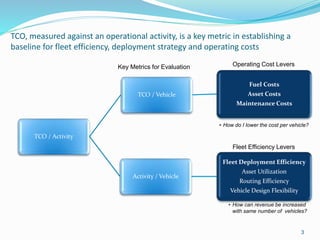

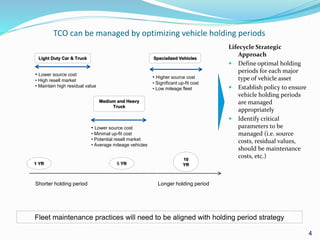

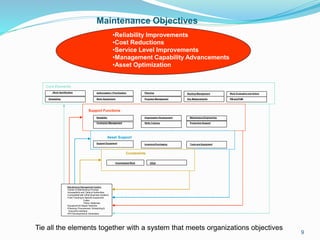

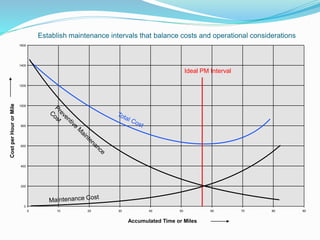

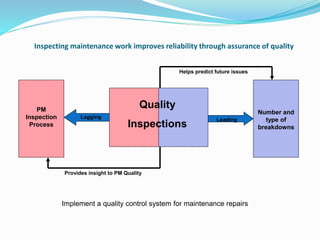

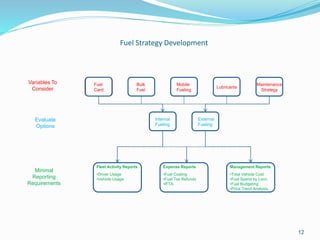

To properly manage fleet costs, understanding total cost of ownership (TCO) is important. TCO includes factors like vehicle assets, maintenance, and fuel. The document discusses how optimizing vehicle holding periods, aligning maintenance programs with holding periods, and determining the right fuel strategy can impact TCO and operations. It also explains that measuring TCO against operational activity is a key metric for establishing a baseline for fleet efficiency and costs.