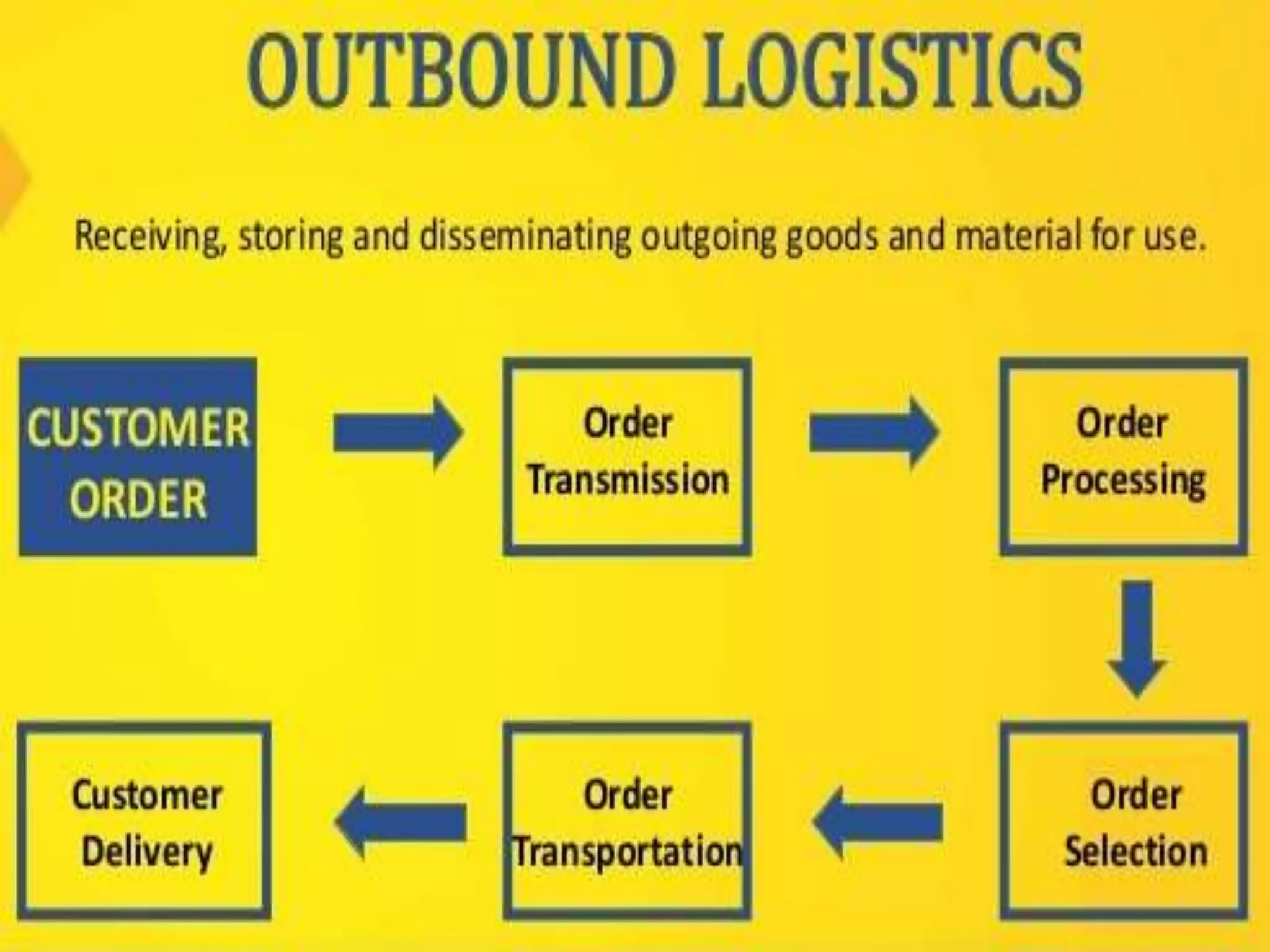

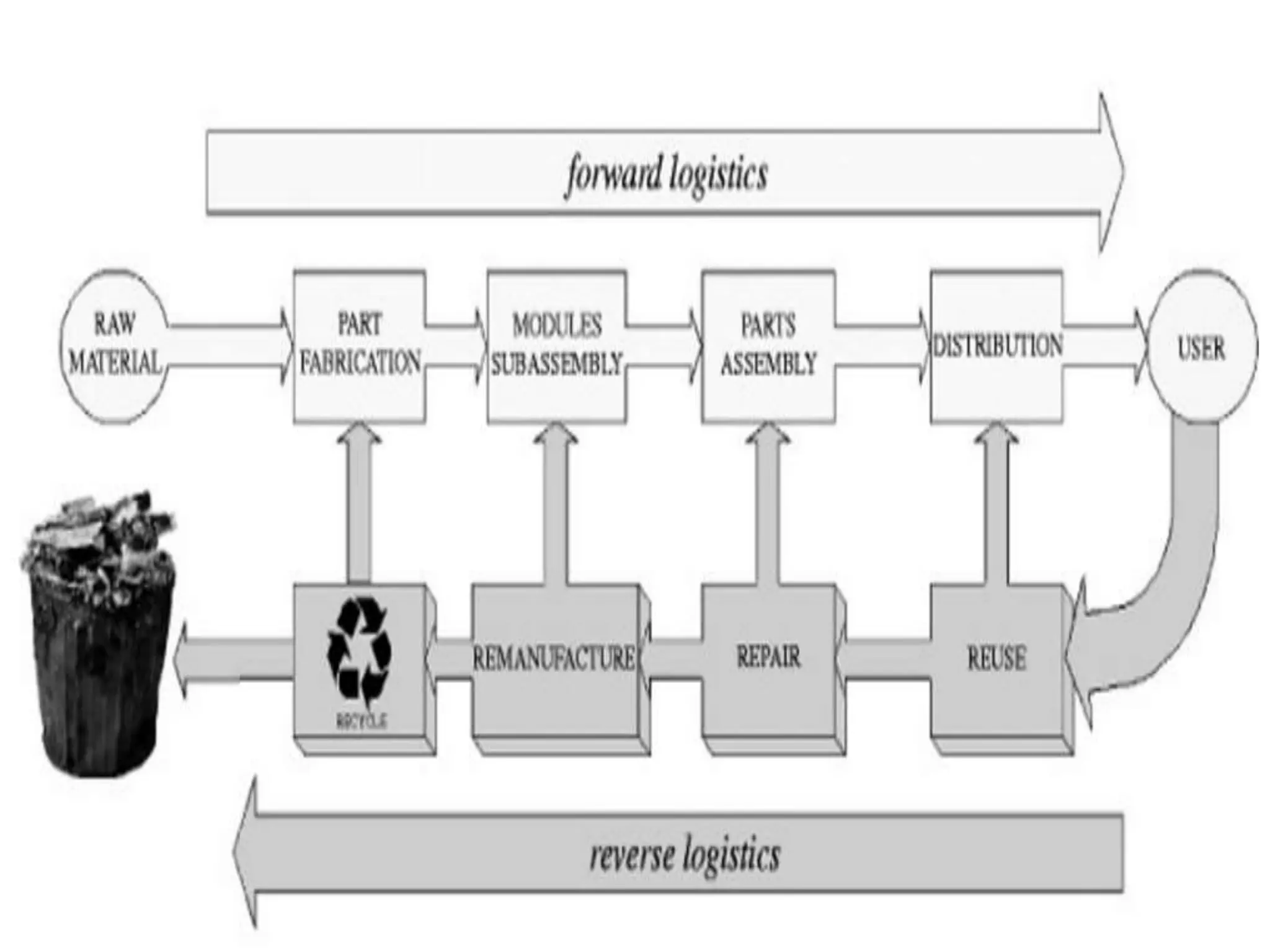

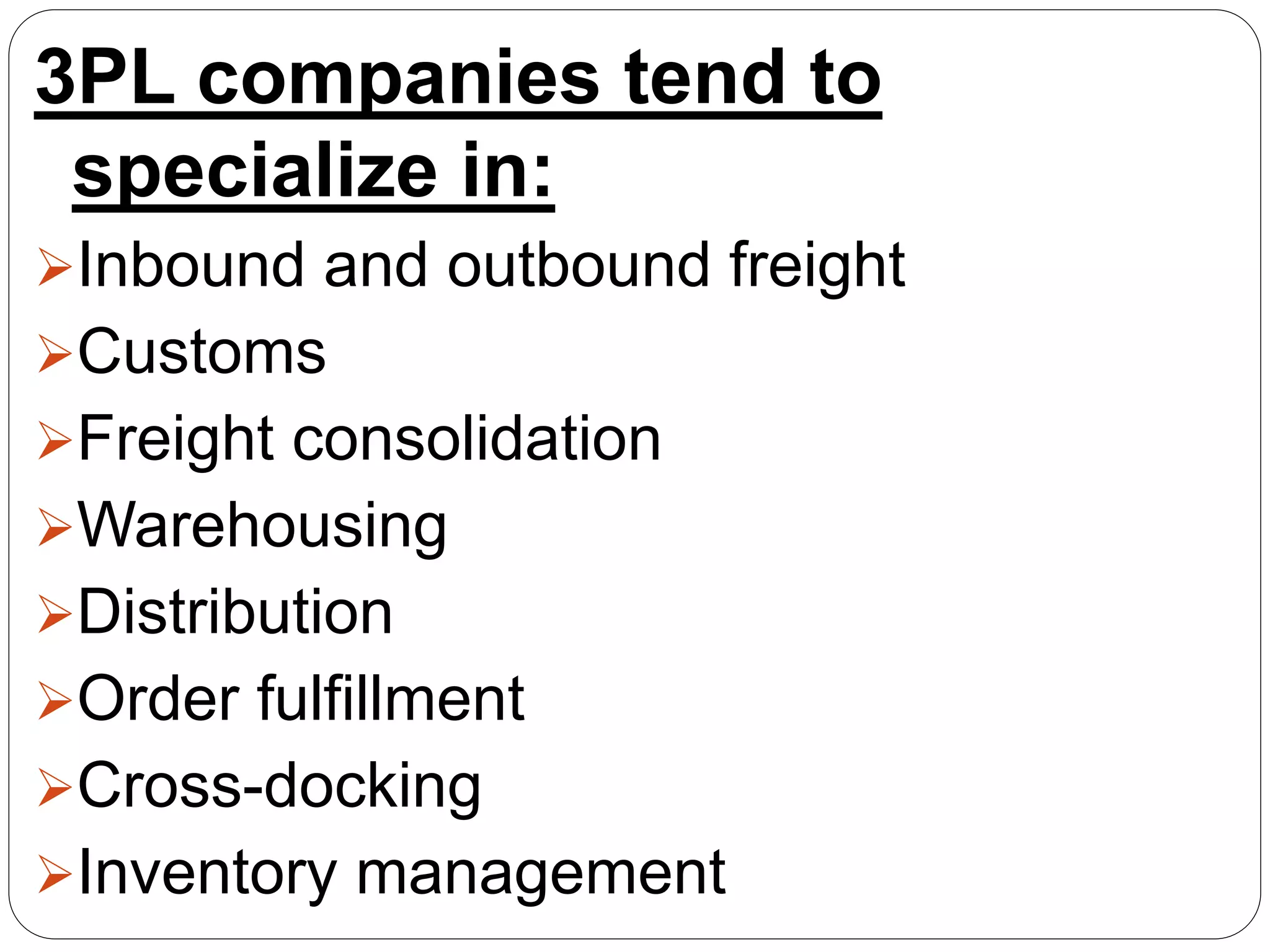

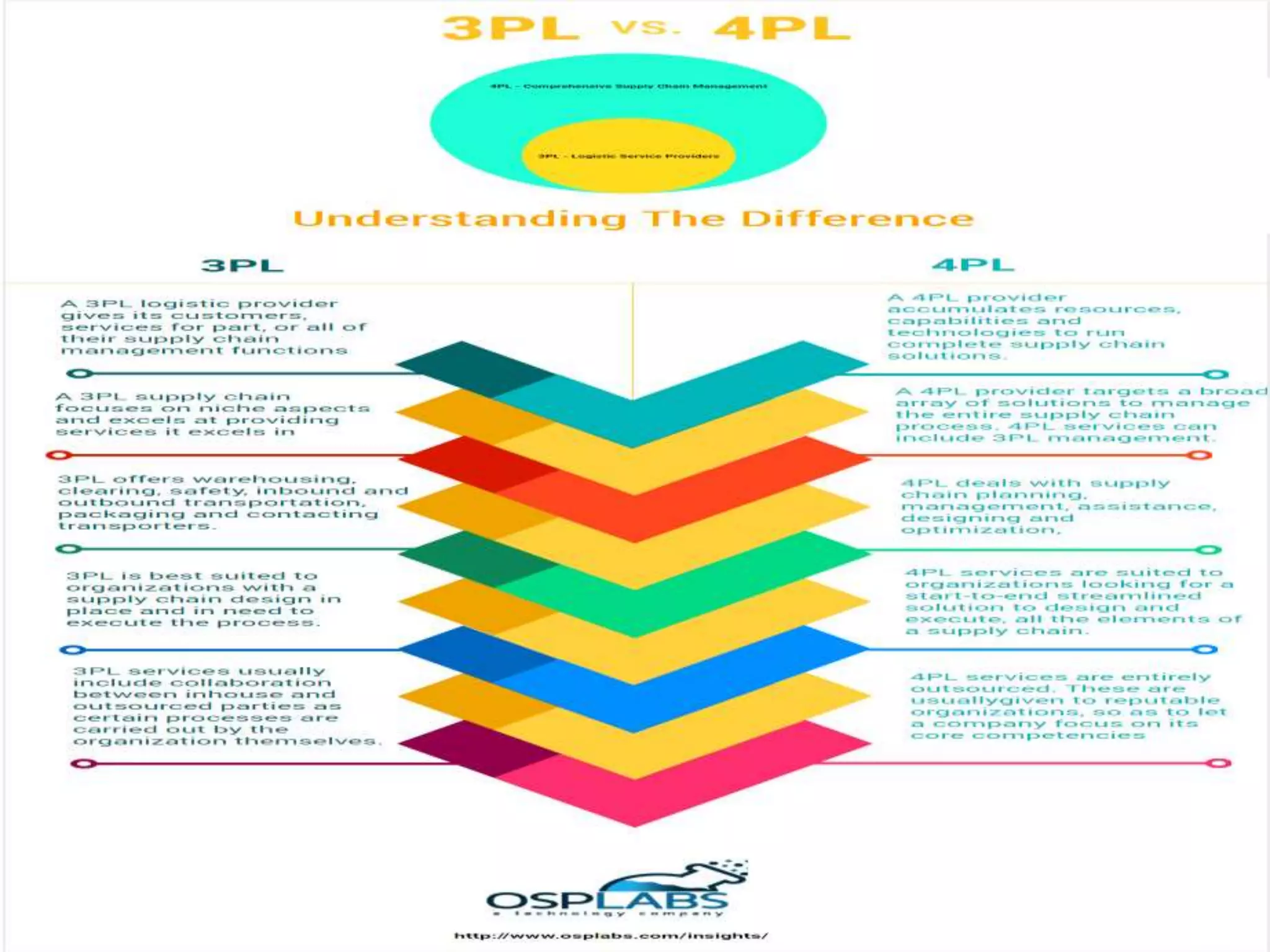

The document provides an overview of logistics management, detailing its components such as inbound, outbound, and internal logistics, as well as the development of integrated logistics strategies aimed at optimizing supply chain management effectiveness. It emphasizes the importance of logistics in maximizing profitability, cash flow, and customer satisfaction through effective inventory management, financial control with suppliers, and the use of third-party logistics (3PL) and fourth-party logistics (4PL) companies. Additionally, it discusses reverse logistics and the necessity of logistics strategies aligning with company objectives to maintain high service levels despite changing supply chain dynamics.