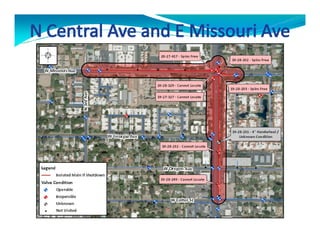

The document discusses challenges facing water utilities including aging infrastructure, reduced staffing, and deferred maintenance. It emphasizes the importance of valve operability for system control and reducing risks like water loss, injuries, and lawsuits. A "run to failure" asset management strategy is not sustainable and will lead to service disruptions. The document recommends taking inventory of assets, assessing conditions, prioritizing critical assets, and developing long-term operation, maintenance, and capital improvement strategies focused initially on large, critical valves to gain control of the system and set up future generations for success.